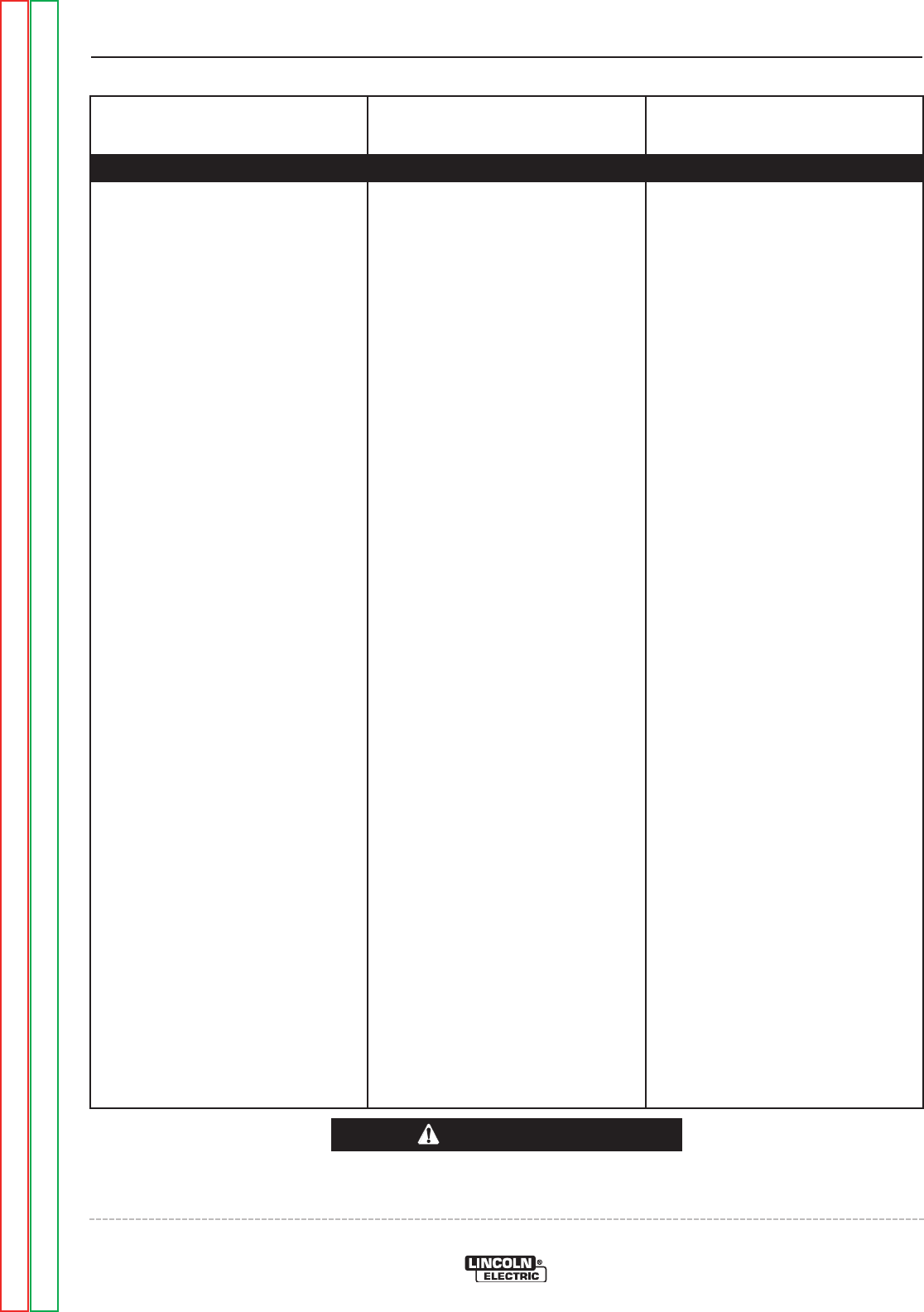

WELDING PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

The welding arc is loud and

spatters excessively.

The weld current or voltage

settings may be incorrect.

The polarity may be incorrect

for the process in use.

If a remote current control is

being used, try switching to

local control. The remote

current control may be faulty.

The engine RPM may be

incorrect; perform the Engine

RPM Adjustment Test.

Check the exciter brushes

and slip rings, and if

necessary, perform the Brush

and Slip Ring Service

Procedure.

Check the DC welding

generator brushes and

commutator. Perform the

Welding Generator Brush

and Commutator Inspection

and Service Procedure.

Replace the Exciter Diode

Bridge with a new or known

good bridge.

(Diode bridges will sometimes

appear good under test, but

fail while under a normal

operating load.)

Perform the Exciter Rotor

Resistance and Ground

Test.

Perform the Shunt Field Coil

Resistance and Ground

Test.

Verify that the rocker is

positioned correctly, according

to the factory drill mark.

Adjust the rocker position per

the procedure in this manual.

TROUBLESHOOTING AND REPAIR

F-9 F-9

CLASSIC® 300D & 300G

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC