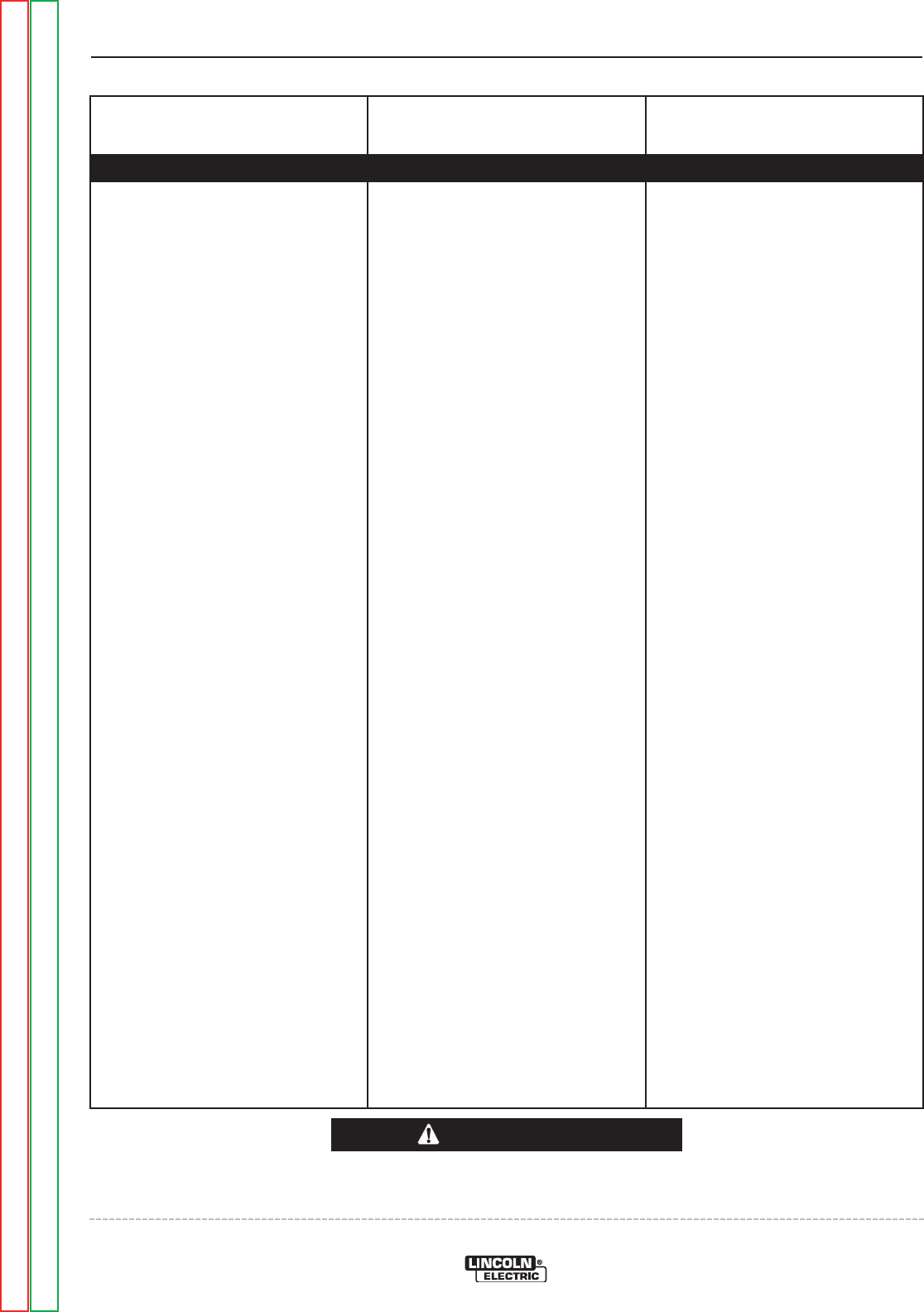

FUNCTION PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

The engine will not go to high

idle when striking an arc. The

automatic idle system functions

normally when using auxiliary

power. Weld and auxiliary

power are normal when the idle

switch is in the “High Idle”

position. The engine starts,

runs, and shuts down normally.

Check that the welding cables,

electrode holder, and work

clamp are tight and in good

condition.

This may be normal operation

if the machine has a Wire

Feed Module, and is operating

in CV mode. See the

operatorʼs manual for the Wire

Feed Module.

Perkins powered models:

The 2 CR Reed Relay, or the

wiring that connect it to the

PC board and chassis ground

may be faulty. The Reed

relay should close when

sufficient current is drawn

from the weld output

terminals.

The idle/engine protection PC

board may be faulty.

Classic® 300G and

Classic® 300D Kubota

powered machines:

The weld current sense wire

that passes through the

current sensor may have a

poor electrical connection.

These leads are not

numbered on Classic® 300G.

on Kubota powered

machines; these are leads

67A and 67B.

Take these connections apart,

clean them thoroughly and

securely reconnect them.

Check the condition of the

crimp connections and

replace any that are loose,

corroded or suspect in any

way.

TROUBLESHOOTING AND REPAIR

F-21 F-21

CLASSIC® 300D & 300G

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC