WELDING GENERATOR BRUSH AND COMMUTATOR

INSPECTION AND SERVICE PROCEDURE (continued)

PROCEDURE

1. Shut off the engine.

2. Open either, or both of the side doors of the

Classic® 300 machine.

NOTE: Secure the doors in the open position using

the door restraint system. If the machine

does not have a door restraint system,

remove the doors or securely restrain them

to prevent them from falling closed.

3. Disconnect the negative battery cable.

4. Remove the cover protecting the welder gener-

ator brushes.

Examine the Commutator:

Normal appearance:

The commutator should appear smooth, and have

an even brown color where the brushes ride.

Blackened Commutator:

A commutator that appears an even black color all

around may indicate a grounded armature, shorted

weld circuit, a serious overload condition, or out-of-

adjustment rocker. It could also indicate the use of

poor quality brushes, or brushes that have been

contaminated with oil or some other foreign sub-

stance.

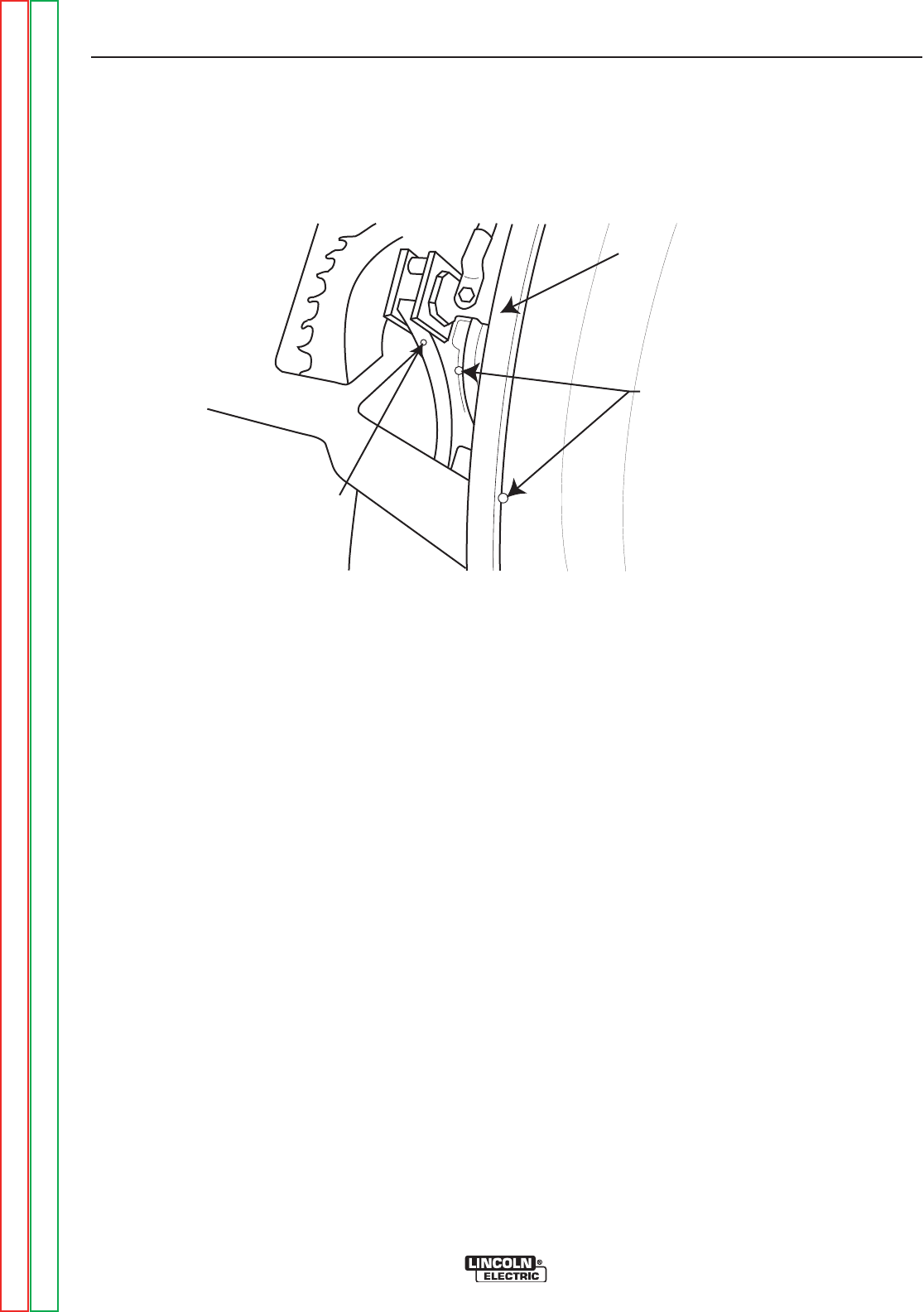

• Check the rocker position. Be certain that it is

aligned with or very close to the factory drill

mark. See Figure F.3. IMPORTANT: If the rocker

position requires adjustment, do not over tighten

the rocker clamping screw. This screw should be

tightened to a torque of 70 to 75 Inch-Lbs. Over

tightening can destroy the rocker.

• Perform the Weld Circuit Ground and Short

Circuit Test.

• If the weld circuit is not grounded or shorted, and

poor brush quality or contamination is suspect-

ed, replace the brushes and seat them with a

commutator stone or sand paper.

• If brush quality or contamination is not suspect-

ed, clean the commutator by lightly stoning the

surface. See caution note on commutator stone

use.

TROUBLESHOOTING AND REPAIR

F-54 F-54

CLASSIC® 300D & 300G

FIGURE F.3 - DRILL MARK LOCATIONS

ROCKER

DRILL MARKS

EXCITER BRACKET

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC