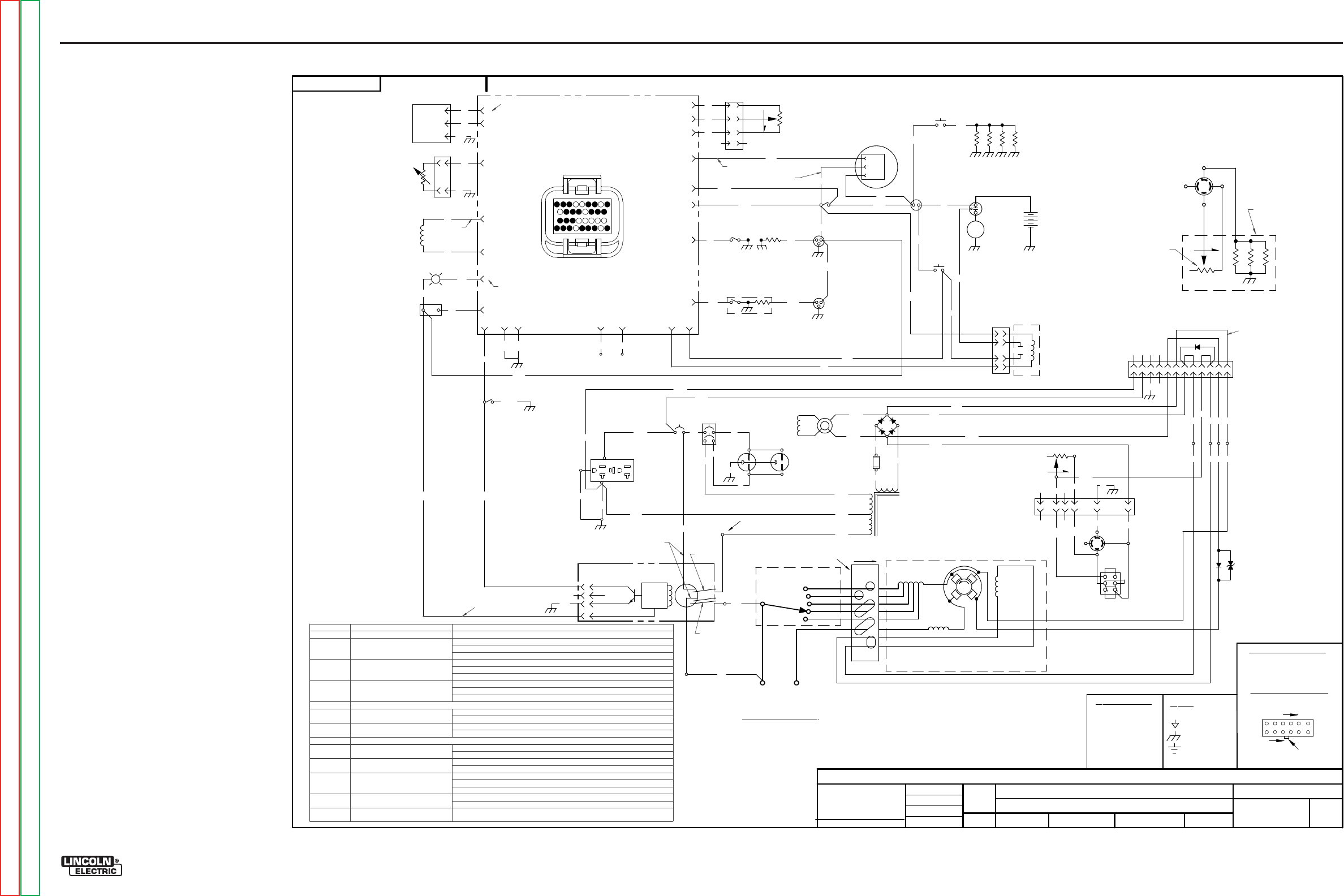

ELECTRICAL DIAGRAMS

G-21

CLASSIC® 300D & 300G

SCHEMATIC - COMPLETE MACHINE - (CODES 11474, 11475) (L13351)

L13351

C

LASS

IC

300

D

K

UB

OTA

MACHIN

E

SCHEM

ATI

C

NO

NE

L13097

DO N

OT S

CA

LE

TH

IS

D

RAW

ING

EQU

IP

ME

NT

TYPE

:

SU

BJ

EC

T:

NA

CRM37

569

1

PA

GE

___

OF

___

1

ENGINE

ERING CONTROL

L

ED

MANUFACTURER:

No

T

HIS

DOC

UME

N

T C

ON

TAINS P

R

OP

RIETA

RY IN

FO

RMATIO

N

OW

NE

D BY L

IN

C

OLN

GLOBAL, IN

C. A

N

D MAY NOT BE

D

UPLI

CA

TE

D,

C

OMMU

NI

CA

TE

D

TO OT

HE

R PA

R

TIES O

R

USE

D

FO

R A

NY P

U

RP

OSE WIT

HOU

T THE E

X

PRESS

W

RITTE

N PE

RMISSIO

N

OF LIN

C

OLN

GLOBAL, IN

C.

PROPRI

ETA

RY & CONFIDE

NTIAL:

Ne

w

t

MAT

ERIAL TOLERANCE (

"

")

TO A

G

REE

WITH PUBLISHED

STANDARDS.

O

N ALL AN

GLES IS

±

.5

OF A

DEG

REE

ON

3

P

LA

C

E

DECIM

ALS

IS

±

.0

02

i

n.

(

±

0.05

mm)

O

N 2

PLACE DEC

IMALS IS

±

.02

in

. (

±

0.5

mm)

U

NLESS

OTHERW

ISE

SPE

C

IF

IE

D

TOLERA

N

CE

:

MANUFACTURIN

G

TOLERANCE PER

E2056

C

HA

N

GE DE

T

AIL:

REFE

RE

N

CE:

SCA

LE:

MATE

RIAL

DISPO

SITION:

APP

ROV

AL

DAT

E:

PRO

JE

CT

NU

MBE

R:

DOCUMENT

N

UMBER:

DOCUMENT

REVIS

I

ON:

U

NITS:

IF

PRIN

TED

@

A2

S

IZE

INC

H

1

1/

1

6/

2007

Maglietta

D. BE

N

DE

R

-

DR

A

WN

BY:

E

NG

IN

EE

R:

CLEVELAN

D

APP

RO

VE

D:

CO

NT

ROL:

A

L13351

EA

RTH

GROU

ND

FRAM

E

G

RO

UND

COMM

ON

LA

B

EL

S:

EX

.

1

2

PIN CONNECTOR

LATC

H

127

6

2

1

VIEW O

F

CONNECTOR ON PC BOARD

CO

NNE

CTOR

P

IN N

UM

BERS:

RESI

STO

R: O

HM

S/W

ATTS

CAPA

CITO

R:

MFD/

V

OLTS

COM

P

ON

E

NT

V

AL

UE

U

NIT

S:

B-BL

ACK

OR

GR

AY

G-GRE

EN

R-RE

D

OR

P

IN

K

U-BLU

E

W-

W

HIT

E

Y-Y

ELLO

W

N-BR

OWN

LE

A

D

COLO

R

CO

DE:

OIL PRESSURE SWITCH / SENDER

TEMPERATURE

SWITCH

TEMPERATURE

GAUGE

S

I

G

OIL PRESSURE

GAUGE

S

I

G

AMMETER

+

-

ENGINE CONTROL UNIT

(

ECU)

1

ENGINE

PROTECTION

LIGHT

ALTERNATOR

WK

G

NEGATIVE OUTPUT

TERMINAL

POSITIVE OUTPUT

TERMINAL

4

3

2

1

GENER

ATOR L

E

AD B

LOCK

SHOWN

A

SVI

EW

ED

WITH

ENGINE IN THIS DIRECTION

-

-

+

+

INTERPOLE

COILS

SHUNT

FIELD

SERIES FIELD

TYPICAL CURRENT

DRAW IS 40 AMPS

+

HOUR METER

12

11

10

9

8

7

65

4

3

2

1

P10

J5

SWITCH CLOSES

AT 6+/-2 PSI

SENDER OPERATION:

0PSI->10+/-5OHMS

40PSI -> 105+/-5 OHMS

80 PSI -> 187+/-5 OHMS

FJW-5AP

COILPAIR:

25.2 - 26.7

OHMS EACH

FLYBACK DIODE PREVENTS

VOLTAGESPIKES IN SHUNT FIELD

FROM DAMAGING LOCAL/REMOTE

TOGGLE SWITCH WHEN SWITCHED

SHOWN IN LOCAL

POSITION

3 TURN

S

2 TURN

S

SENSOR GROUNDS LEAD

ON SENSE OF WELD OR

AUXILIARY LOAD

Y

RHEOSTAT

W

G

X

REMOTE

RECEPTACLE

LOCAL / REMOTE

SWITCH

S

WITCH CLO

SES

AT

110v+/

-3

vC

S

END

ER OP

ER

ATION:

90v

C

->

51.

2+/

-4.3 OHMS

P9

J8

46531 2

64+/-6.4 OHMS MAX

WITH

AC AU

X

ILIARY POW

ER,

ROUTING

DIRECTIONS OF THES

E

LE

AD

S DOE

S NOT

M

AT

TER

BRUSH POSITION SHOWN AS

VIEWED FROM CONTROL PANEL

+

_

COLOR: RED

12 VOLT

NORMALLY OFF

SHOWN IN"OFF"

POSITION

53

51C

50

50A

51

51A

212D

43

200

54

44

212A

212B

61

844A

841

844

N

U

67A

602B

602

SELECTOR SWITCH

90-MIN

130-80

190-120

240-160

220-MAX

WELDING

GENERATOR

CCW

-40 TO 40 AMPS

AMMETER SHOWS FULL

DISCHARGE WHILE PRESSING

GLOW PLUG SWITCH

40AMP/12VOLT

IG

B

L

GLOW PLUGS

12.6 VOLTS MIN

ATREST

14-14.5 VOLTS

WHILE RUNNING

BACK, BOTTOM

OFMACHINE

JUMPER PLUG IS FOR CONNECTION

TO WIRE FEED MODULE

LOCATEDBEHINDUPPER PORTIONOF CONTROL PANEL

LOCATEDBEHINDUPPERLEFT

PORTION OFCONTROL PANEL

TYPICAL OCV(WARM MACHINE):

94-99.0 VOLTS AT MAX RHEOSTAT

44-54.5 VOLTS AT MIN RHEOSTAT

DRIVER

CIRCUITS

JUMPERPLUG ISWIRE-TIED UP

BEHIND LOCAL / REMOTESWITCHON

R IGHTS IDEOFM AC HINE(A SV IE WED

FROMCONTROL PANEL)

1

2

3

WATER

TEMP.

SENSOR

ENGINE

SPEED

SENSOR

31

60F

19

58

6

IGNITION

SWITCH

212C

12

START

BUTTON

7

52A

52B

55

62

STARTER

RELAY

RELAY CONTACTS FOR 52 AND 52A ARE NORMALLY

OPEN. THE STARTER MOTOR CAN ONLY BE ENGAGED

WHEN THE IGNITION SWITCH IS "ON" AND THEECU

SENSES LESS THAN 700 RPM. IF THE ENGINE IS SHUT

DOWN DUE TO A FAULT

(EVEN

IF T

H

AT

CO

ND

IT

IO

N

DO

ES

NOT

RES

ULT

IN A

FL

ASH

CO

DE, SUCH AS RUNNI

NG

OUT

OF

F

UE

L)

, THEIGNITIONSWITCHWILL NEED TOBE

TURNED OFF THEN BACK ON TO RESTART THE ENGINE.

4

87

86

88

11

2

3

10,000 +/- 1,000 OHMS MAX

TURN POT COUNTERCLOCKWISE TO

REDUCE RESISTANCE AND SUBSEQUENTLY

REDUCE RPM BY UP TO 150RPM

RATED VOLTAGE: 12V

RATED CURRENT: 22mA MAX

60

S

EN

SOR OPER

ATION:

-4

v

F

->

18.

8

0 kOH

MS

104

v

F

->

1.14

kOHM

S

212

v

F

->

.16 kOH

MS

RATED VOLTAGE: 12V

RATED CURRENT: 4.5A(MAX.)-TERMINAL #15

LEAKAGE CURRENT 10micro A (MAX.)-TERMINAL #16

57 34

RAT

ED VO

LT

AGE: 1

2V

RAT

ED CURRENT: 2

A

COIL RESI

ST

ENC

E:

2.8

+/-

.28 OH

M

S

AT

20vC

EN

ERGIZED FOR RUN

DE-ENERGIZED FOR STOP

ACTU

ATOR CONTROLS R

PM

DOWN THE

ENGINE A

T 1

15%

OF RATED

SPE

ED.

27

28

841A

9

212E

26

64

16

15

51B

70A

70B

CONNECT TO

GROUND FOR

800RPM

CONNECT TO

GROUND FOR

1600RPM, LEAVE

UNCONNECTED

FOR 1800RPM

30

32

61

0A

+

-

+

-

21

5

81

0

82

0

SLIPRINGS

21

4

AC

AC

48

GND-

T

11C

21

EXCITER STATOR

(ALTERNATOR)

11B

POSITIVESLIP RING

IS NEAREST TO IRON

EXCITER REVOLVING

FIELD(ROTOR)

400E

400D

15A

610

610

600B

600A

42

600

41

602A

67B

60E

INTERPOLE

COILS

ACTUATOR

56

18

69

13

60A

94

20

93 17

CCW

RPM CONTROL POTENTIOMETER

WIRE-TIEDTOHARNESS

BEHIND CONTROL PANEL

FUSE

BOTHOPENLEADSAREWIRE-TIED INSIDE THEHARNESS BEHINDCONTROLPANEL

SHOWN IN "AUTO

IDLE" POSITION

IDLER SWITCH

GND-B

841B

WINDING SPEC: ALT-241-3A

40.5 - 42.5 OHMS AT 25C

EXCITER CIRCUIT

LEAD 21A TO 21B

WINDING SPEC: ALT-214-2B

.488 OHMS MAX AT 25C

115

V

OLT

CIRCU

IT

L

EAD

8

10

TO

8

20

WINDI

NG

SPEC: A

LT-214

-2

C

.2

30

O

HM

S

M

AX

AT

2

5C

115

V

OLT

CIRCU

IT

L

EAD

8

20

TO

8

30

WINDI

NG

SPEC: A

LT-214

-2

D

.4

24

O

HM

S

M

AX

AT

2

5C

1

2 VO

LT

SU

PP

LY

THE

ECU WI

L

L INDICAT

E FAU

LT CONDITIONS BY FLA

SHING THE

ENGINE PROT

ECTION LIGHT IN A CODED SEQU

ENC

E, S

E

E CHAR

T

FOR FAULT CODE

S

AND CORRECTIV

E

MEA

SUR

E

S. WH

EN TH

E

ENGINE IS

SHUT DOWN DUE

TO A FAU

LT, TH

E IGNITION

S

WITCH

WI

L

L NE

ED TO B

E TURN

ED OFF THEN B

AC

K ON

TO RES

TAR

T THE

ENGINE.

1

2 VO

LT

SU

PP

LY

N

U

GLOW PLUG

BUTTON

+

BATTERY

STARTER

MOTOR

STARTER

SOLENOID

842

42

W

W

Y

Y

MOU NTEDTONEGATIVE

BRUSHHOLDER

THIS CIRCUIT USES THE

RESIDUAL MAGNETISM OF

THE GENERATOR TO FLASH

THE EXCITE THE ROTOR

WHICH IN TURN PROVIDES

THE EXCITATION FOR THE

GENERATOR

D

IO

DE AND

MO

V ASS

EM

BLY

IN

-LINE BOLT

ED CONNECTION

B

EHIND CONTROL PAN

EL

60

0C

FRONT, RIGHT SIDE

OF ENGINE

FRONT, LEFT SIDEOF ENGINE

BACK, LEFT SIDEOF ENGINE

JUMPER PLUGIS BEHINDLOWER

RIGHTSIDEOF CONTROL PANEL

LOWER, RIGHT SIDEOF CONTROL PANEL

DIODE

LOW ER,

RIGHT OF

CONTROL

PANEL

LOW ERLEFTOF

CONTROL PANEL

LOW ERLEFTOF

CONTROL PANEL

CENTER OF

CONTROL PANEL

BACK, RIGHT

S IDEO FENGINE

BACK, LEFT

SIDE OF ENGINE

BACK, RIGHT

SIDE OF ENGINE

CENTEROF

CONTROL PANEL

UNDERLEFT DOOR

LOWER RIGHT OF CONTROL PANEL

44

28

1

2 VO

LT

SU

PP

LY

ECU CONNECTOR DETAIL

9

17

25

34

26

18

10

1

FL

A

SH

E

S

A

LT

ERN

ATOR

S

EN

SE

S

A

LT

ERN

ATOR OUTPU

T

THE

P1

0 P

LUG IS ONLY

ON UN

ITS

WITHOUT TH

E

WIR

E FE

ED

MODU

L

E.

THE

WIR

E FE

ED

MODU

L

E HA

S

A

HARNE

S

S TH

AT

P

LUGS DIREC

TLY

INTO J5.

41

JUMPERPLUG IS

WIRE -TIE DU P

BEHIND LOCAL /

REMOTE SWITCH

ONRIGHT SIDEOF

MACHINE

SCHEMATIC S25973

CURRENT SENSING PC BOARD

602B

400F

WH

ITE

LOA

DWH

ITE

LI

NE

HOT

LOA

D

HOT

LI

NE

115 VOLT GFCI

RECEPTACLE

400D

CB2

15A

6A

810

230 VOLT

RECEPTACLE

7A

6A

GND-E

11A

CB1

20A

82

0

GND-S

FRONT, RIGHT SIDE

OF ENGINE

BACK, LEFT SIDE

OF ENGINE

TEMPERATURE

SENSOR

LIGHTCODE

FAILUREDETECTED

POSSI BLECAUSE-CORREC TIVEMEASURE

LONG 1, SHORT 1

RPM IS OVER 115% OF RATED RPM (2070 RPM)

ACTUATOR IS STUCK -REMOVEACTUATOR ANDVERIFYPLUNGER PULLSIN WHEN ENERGIZED

LOW OIL -CHECK OIL LEVEL ON DIPSTICK

FAULTY OILPRESSURE SWITCH -CHECKTHAT "WK"STUDIS OPEN WHEN ENGINE IS RUNNING

LEAD TO OIL PRESSURE SWITCH "WK" STUD MAY BE GROUNDED -CHECK

BROKEN OR LOOSE BELT - INSPECT

LEAD TO "L" TERMINAL ON ALTERNATORMAY BE SHORTED TO GROUND -CHECK

FAULTY ALTERNATOR -CHECK

AMOUNT OR QUALITY OF COOLANT INCORRECT -CHECK

FAULTY WATER TEMPERATURESWITCH- CHECK THAT "WK" STUDISOPEN WHEN ENGINE IS NOT RUNNING

LEADTO WATER TEMPERATURE SWITCHMAY BEGROUNDED- CHECK

LONG 1, SHORT 5

FAULTY RPM SENSOR - CHECKFOR GOODCONNECTION

FAULTY ECU - CHECK FOR 12 VOLTS ON SUPPLY LEAD TORPM SENSOR FROMECU

FAULTY ACTUATOR -CHECKFOR PROPER COIL RESISTANCE

LEADS TO ACTUATOR MAYBE OPENOR GROUNDED -CHECK

LONG 2, SHORT3

FAULTY WATER TEMPERATURE SENSOR - CHECK FOR PROPER RESISTANCE

LEAD TO WATER TEMPERATURE SENSORMAY BE OPEN- CHECKFOR CONTINUITY

FAULTY WATER TEMPERATURE SENSOR - CHECK FOR PROPER RESISTANCE

LEAD TO WATER TEMPERATURE SENSORMAY BE GROUNDED - CHECK

LEAD TO "L" TERMINAL ON ALTERNATORMAY BE OPEN- CHECKFOR CONTINUITY

BROKEN OR LOOSE BELT - INSPECT

FAULTY ALTERNATOR -CHECK

INCORRECT BATTERY -INSPECT

FAULTY ALTERNATOR -CHECK

LONG 2, SHORT 8

LESSTHAN 4 VOLTS TO RPMSENSOR AND/OR

ACTUATOR SENSED BYECU

FAULTY ECU - CHECK FOR 12 VOLTS ON LEADS TO RPM SENSOR AND ACTUATOR FROM ECU

NOT ENABLEDFOR LINCOLN PRODUCTS

NOT ENABLEDFOR LINCOLN PRODUCTS

0 RPM IS DETECTED AND 12VIS DETECTED

FROM "L"TERMINAL ON ALTERNATOR

LONG 2, SHORT 1

LONG 1, SHORT 4

HIGH WATER TEMPERATURE DETECTED FOR1

SECOND

LONG 1, SHORT 2 LOW OIL PRESSURE DETECTED FOR 1 SECOND

LONG 1, SHORT 3

"L" TERMINALIS GROUNDEDON ALTERNATOR

FOR 1SECOND

LONG 2, SHORT 7 OVER 18 VOLTS DETECTEDFROM ALTERNATOR

CURRENT TOACTUATOR IS OUT OF LIMITLONG 2, SHORT 2

LONG 2, SHORT 6

0 VOLTSDETECTED FROM "L" TERMINAL ON

ALTERNATOR FOR 1 SECOND

LONG 2, SHORT 5 150C WATER TEMPERATURE DETECTED

-50C WATER TEMPERATURE DETECTED

LONG 2, SHORT4

K924-5 REMOTE CONTROL

(OPTIONAL)

RHEO

STAT

R

EM

OTE

CO

NTROL

BOX

2

5+/-1.

25

OHM

S

EACH

6

4+/-6.

4

OHM

S

MA

X

CCW

Y

W

G

X

R

EM

OTE

CO

NTROL

PL

UG

G-21

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC