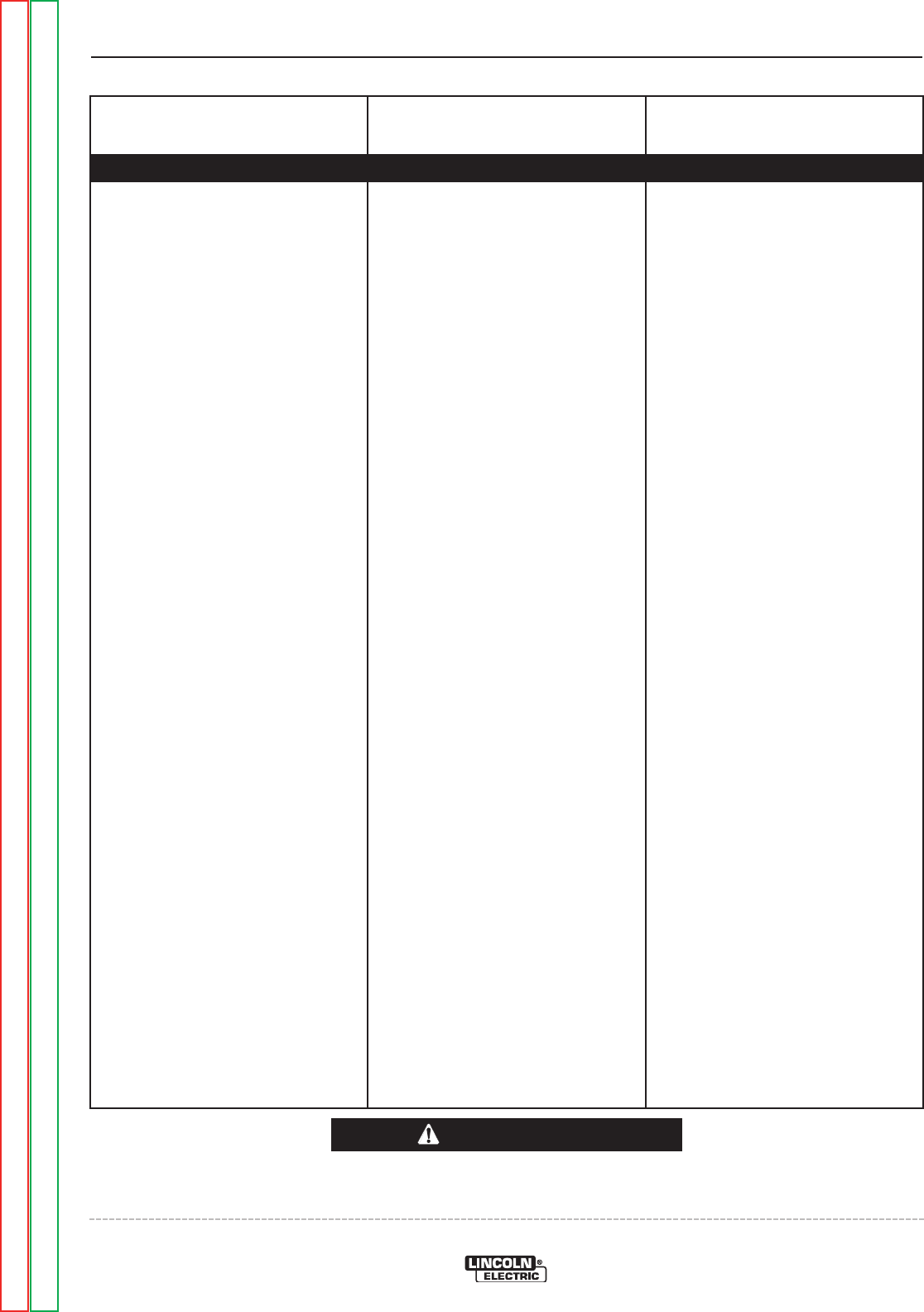

FUNCTION PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

The machine will not idle down

to low RPM when weld and

auxiliary loads are removed.

The machine has normal weld

and auxiliary output. The engine

starts and shuts down normally.

Make sure the idle switch is in

the “AUTO IDLE” position.

Make sure there is no external

load on the weld terminals or

the auxiliary power

receptacles. Disconnect the

weld cables and unplug

anything that may be

connected to the auxiliary

receptacles.

For machines equipped with

an idle solenoid, check for

mechanical restrictions in the

idler solenoid linkage.

Check the Idle Switch for

proper operation. See wiring

diagram.

Perkins powered units:

The idle solenoid linkage, if

so equipped, may be bent or

out of adjustment. Check that

the linkage moves freely and

that the plunger does not bind

in any way.

Check that the solenoid can

freely pull in and solidly seat

against its internal stop.

The idle solenoid may have

failed. Disconnect the

solenoid leads and check the

resistance of the solenoid

coil. See machine schematic

for correct solenoid coil

resistance. Check the

resistance from the solenoid

leads to the solenoid body,

resistance should be very

high, 500,000 (500k) ohms

minimum.

Perform the Engine RPM

Adjustment Test.

The 2-CR Reed relay may be

faulty. The reed relay should

be electrically open if no

current is flowing in the weld

circuit. If there is continuity

through the reed relay when

the machine is off, it is

defective and should be

replaced.

There may be voltage in the

toroidal current sensor circuit.

Unplug the current sensor

from the PC board. See

wiring diagram.

TROUBLESHOOTING AND REPAIR

F-17 F-17

CLASSIC® 300D & 300G

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC