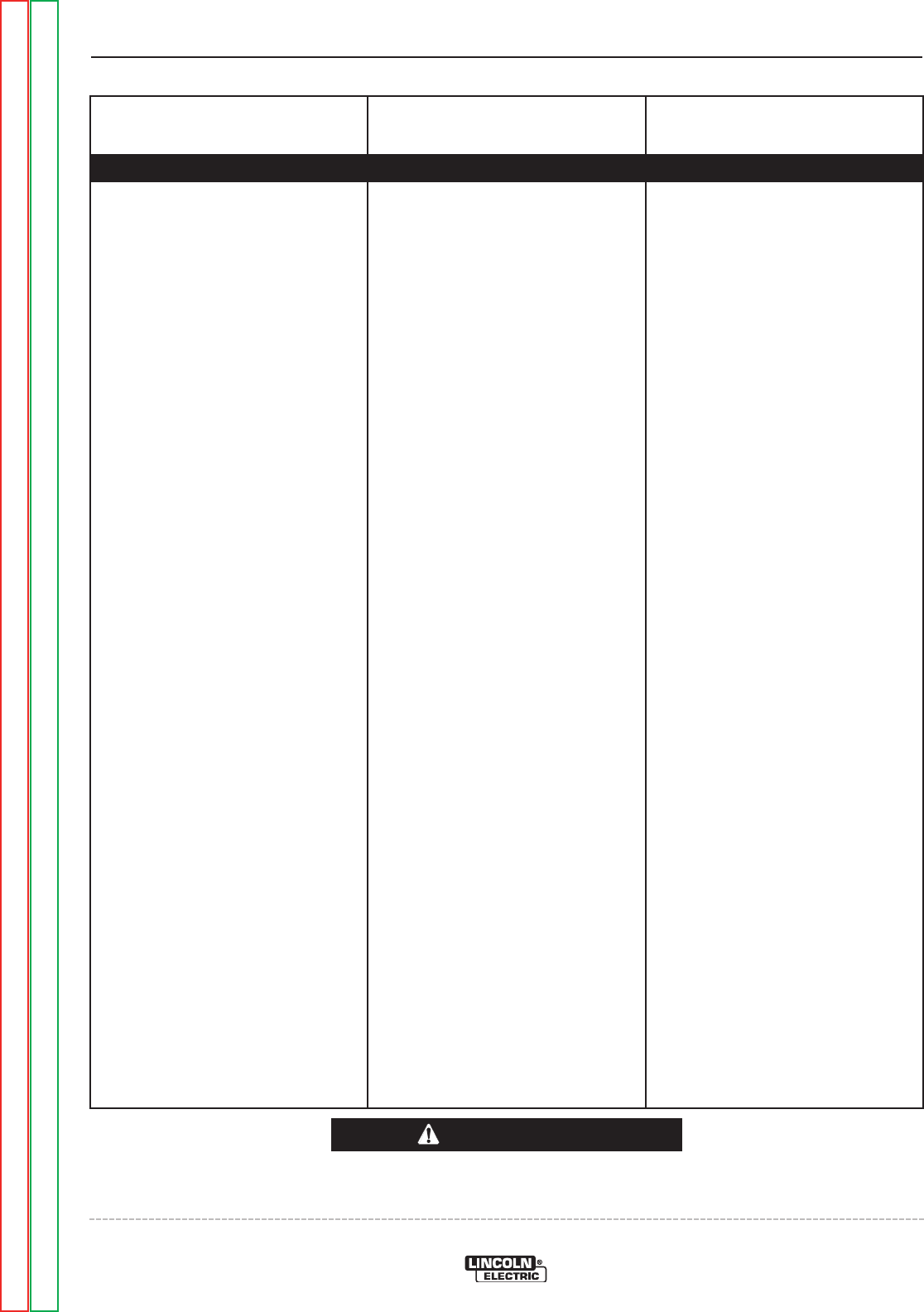

FUNCTION PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

The machine will not idle down

to low RPM when weld and

auxiliary loads are removed.

The machine has normal weld

and auxiliary output. The engine

starts and shuts down normally.

(Continued)

If the machine idles down

after the sensor is unplugged,

check the wiring between the

PC board and toroidal current

sensor for damaged insulation

and electrical contact with

other electrically live

components. (See the wiring

diagram) If the wiring is

good, there is likely a load on

the auxiliary circuit. Check all

wiring and components in the

AC auxiliary circuit. (See

wiring diagram)

If the machine still will not

idle down, check all wiring

connected to the solenoid.

See the wiring diagram. Look

for damaged wiring, poor

connections, dirty or corroded

terminals, etc. If all of the

wiring is good, replace the PC

board.

For Classic® 300G and

Kubota powered units:

Unplug the current sensor PC

board.

If the machine will not idle

down, check all the wiring

connecting to the current

sensor.

If all the wiring is good,

replace the engine control

unit.

If the engine idles down when

the sensor is disconnected,

reconnect the sensor, then

disconnect the leads that loop

through the current sensor

sensing unit. (See wiring

diagram)

If the engine does not idle

down, replace the current

sensor PC board.

TROUBLESHOOTING AND REPAIR

F-18 F-18

CLASSIC® 300D & 300G

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC