Adjustments

'< .C<61 =<@@6/92 6;7B?F

1

6@0<;;20A =9B4 3?<: =<D2?

@<B?02 /23<?2 =2?3<?:6;4 .;F .@@2:/9F

.17B@A:2;A@<??2=.6?@

2.1@@2:/9F <08$6;

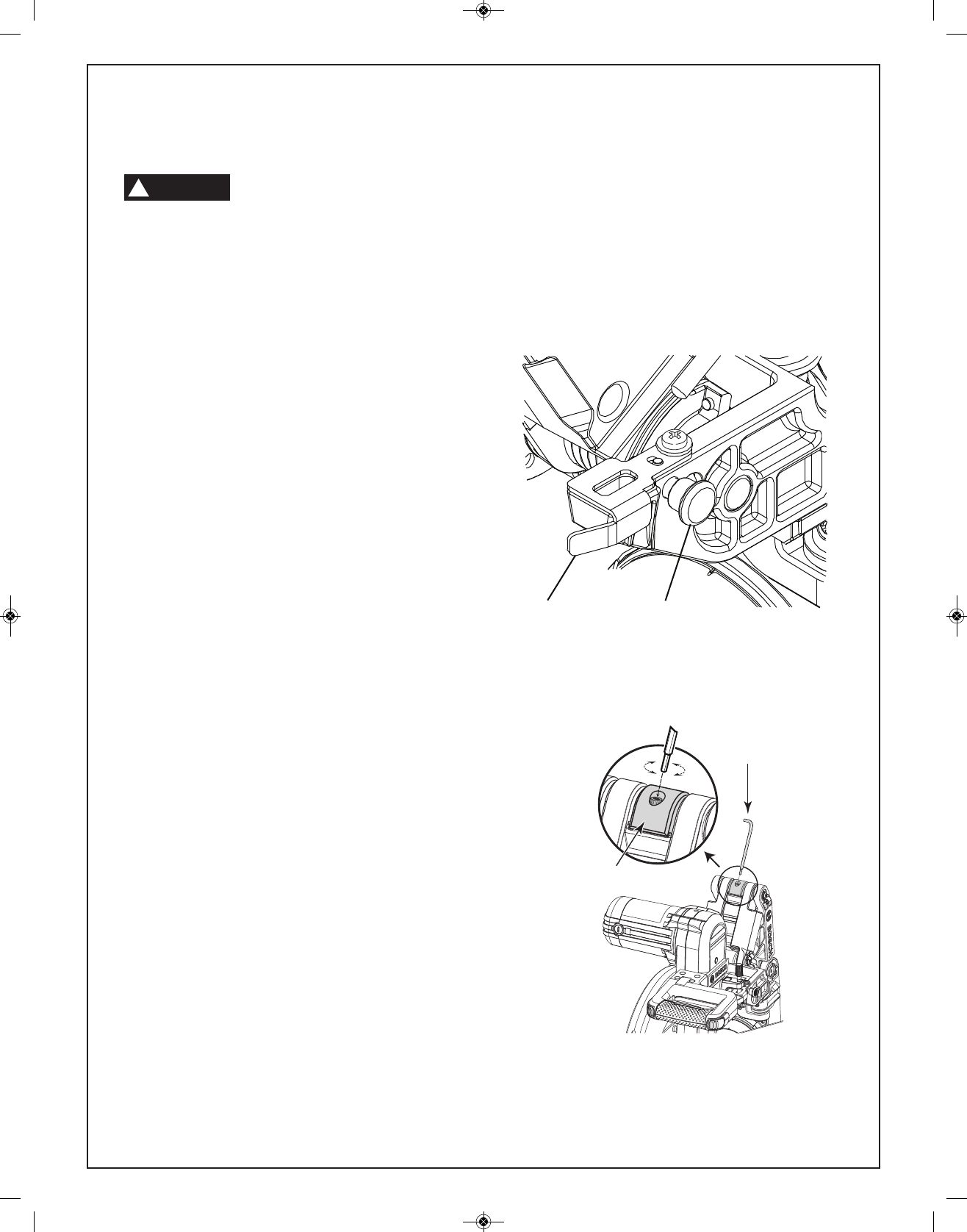

T

he head assembly lock pin (item 43 - page 9) is

located on the right side of the pivot post (item 34 -

page 9). It is used to hold the saw’s head assembly

in the DOWN position. This position prevents the

head from bouncing up and down during

transportation. This also makes the saw more

compact for lifting and storage. This position is also

required for some calibrating procedures.

'<;4.42A522.1@@2:/9F <08$6;

1. Check that the depth stop plate (item 33 - page 9)

is disengaged, or pressed in to the left position.

2. Grasp the saw’s main handle (item 3 - page 8) and

press down on the head assembly.

3. While pressing the saw head down, push in on the

head assembly lock pin. Release the head

assembly. The head will be locked in the DOWN

position (see Figure 11).

'<6@2;4.42A522.1@@2:/9F

<08$6;

1. Grasp the main handle and press down on the

head assembly.

2. While pressing the head down, pull out the head

a

ssembly lock pin. Release the lock pin, but

maintain your grip on the main handle. Slowly

allow the spring-loaded saw head to come up to

the top of its travel and then release the handle.

64B?2

*%""

!

Depth Stop

Plate

Head Assembly

Lock Pin

(@6;4A522.1@@2:/9F <08$6;

'<17B@AA529612!<C2:2;A

<;A?<992?

The glide movement controller is attached to the

upper joint of the glide mechanism; it is designed to

control the smoothness of the saw’s glide action.

When assembled at the factory, the controller is not

adjusted; therefore, the movement is very smooth. To

adjust the glide mechanism’s smoothness, slightly

tighten or loosen the two screws at the top by using

the 6/4mm hex key or a 4mm hex key (see Figure 12).

64B?2

6/4mm Hex Key

x 2 Screws

Glide Movement

Controller

(@6;4A529612!<C2:2;A<;A?<992?

BM 2610007877 04-10:BM 2610007877 04-10.qxp 4/26/10 8:13 AM Page 17