Emerson Process Management GmbH & Co. OHG1-18

X-STREAM XEFD

Instruction Manual

HASXEDE-IM-EX

03/2012

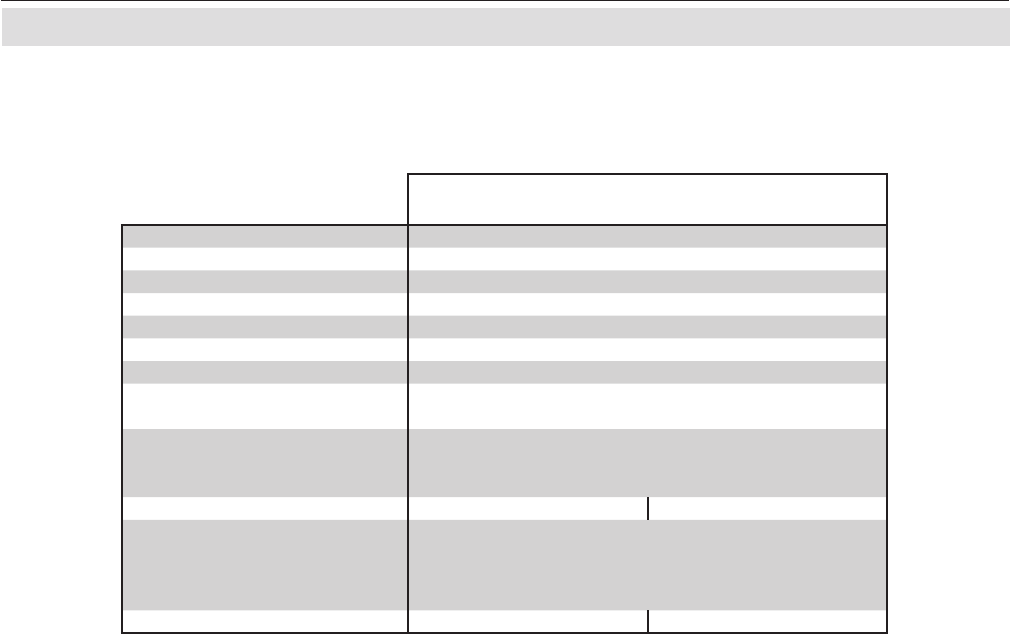

1.8 Measurements Specications

Special Performance Specications for Gas Purity Measurements (ULCO & ULCO

2

)

Tab. 1-10: Special Performance Specications for Gas Purity Measurements

1

Related to full scale

2

Constant pressure and temperature

3

Within 24 h; daily zero calibration requested

4

Within 24 h; daily span calibration recommended

5

Related to measuring value

6

Temperature variation: ≤ 10 K per hour

7

From gas analyzer inlet at gas ow of 1.0 l/min

8

Barometric pressure sensor is required

9

Whichever value is higher

10

Limited to atmospheric if internal sample pump

11

Special conditions apply to pressures above

1100 hPa

(1.5 psig) up to 1500 hPa (7 psig)

0–10…< 50 ppm CO

0–5…< 50 ppm CO

2

Detection limit (4 σ)

1 2

<

2 %

Linearity

1 2

< 1 %

Zero-point drift

1 2 3

< 2 % resp. < 0.2 ppm

9

Span (sensitivity) drift

1 2 4

< 2 % resp. < 0.2 ppm

9

Repeatability

1 2

< 2 % resp. < 0.2 ppm

9

Response time (t

90

)

7

< 10 s

Permissible gas ow 0.2–1.5 l/min.

Inuence of gas ow

1 2

< 2%

Maximum gas pressure

10 11

≤ 1500 hPa abs.

(≤ 7 psig)

Inuence of pressure

5

– At constant temperature ≤ 0.1 % per hPa

– With pressure compensation

8

≤ 0.01 % per hPa

Permissible ambient temperature +15 to +35 °C (59 to 95 °F) +5 to +40 °C (41 to 104 °F)

Inuence of temperature

6

(at constant pressure)

– On zero point < 2 % per 10 K resp. < 0.2 ppm per 10 K

9

– On span (sensitivity) < 2 % per 10 K resp. < 0.2 ppm per 10 K

9

Thermostat control none 60 °C (140 °F)

Note! 1 psi = 68.95 hPa