Emerson Process Management GmbH & Co. OHG 2-5

2

Installation

X-STREAM XEFD

Instruction Manual

HASXEDE-IM-EX

03/2012

2.3 Installation - Gas Lines

Gas ttings are accessible at the instrument‘s

outer bottom side.The number and assign-

ment of gas inlet and outlet ttings depends

on the application and is given on a label at-

tached to the analyzer‘s bottom side adjacent

to the ttings.

For simple installation we recommend to

mark the gas lines according to the marking

on the analyzer label. This avoids confusion

during re-installation if the analyzer had to be

disconnected for whatever reason.

2.3.1 Special Conditions

The purge medium must be supplied via a

separate ame arrestor (purge gas inlet),

installed into the analyzer enclosure. Another

ame arrestor must be installed, operating as

a breathing device (purge gas outlet).

Connection of breathing device:

The external output of the breathing device

(exhaust) can be open to the ambience of the

analyzer, if inert gas is used as purge medium.

If air is used, the output must end in a safe

area, if the measured gas concentration is

above

25 % V/V LEL.

2.3.1.1 Purging the Housing with Clean Gas when e.g. Measuring Low Concentrations

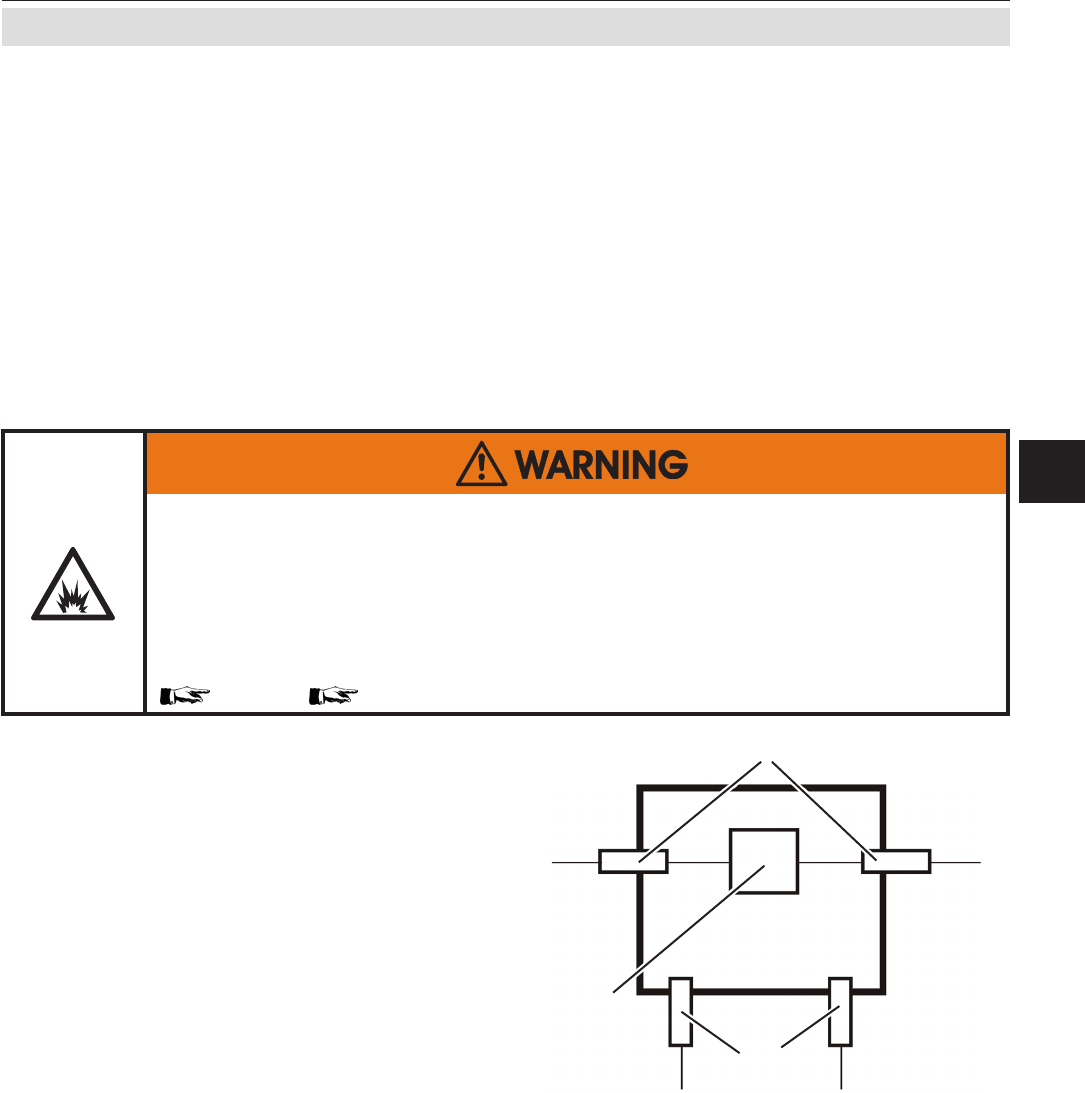

Fig. 2-5: Exemplary diagram for a single channel unit with purge option

1

2

3

1: Flame arrestors for gas path

2: Measuring system

3: Flame arrestors for purge gas in-/outlet

EXPLOSION HAZARD BY HIGH PRESSURE

Risk of internal overpressure under leakage conditions!

For the following option, take care to limit the total of purge gas ow and

highest ow of sample gas lines into the instrument to max. 2 l/min!

Take care of special conditions for safe use, and gas parameter specications

( S-5 and 1-12)!