Emerson Process Management GmbH & Co. OHG2-6

X-STREAM XEFD

Instruction Manual

HASXEDE-IM-EX

03/2012

2.3 Installation - Gas Lines

The gas paths need additionally to be

protected by suitable external inline ame

arrestors, designed and approved for the in-

stallation area and for the applied higher gas

pressure (above 1100 hPa to max. 1500 hPa;

see gas parameter specication 1-12 ).

These inline ame arrestors need to be in-

stalled outside the analyzer and in addition to

the ame arrestors provided by the analyzer.

Note!

The external inline ame arrestors are not

subject of the analyzer certication and may

be provided by the customer, or optionally by

EMERSON PROCESS MANAGEMENT.

A separate analyzer ame arrestor has to be

installed, operating as a breathing device,

limiting the internal pressure rise in case of

gas path leakage.

Connection of breathing device:

The external output of the breathing device (ex-

haust) may be open to the ambience of the ana-

lyzer, if the measured gas concentration is below

25 % V/V LEL. Otherwise it must end in a

safe area.

2.3.1.2 High Sample and Calibration Gas Pressures

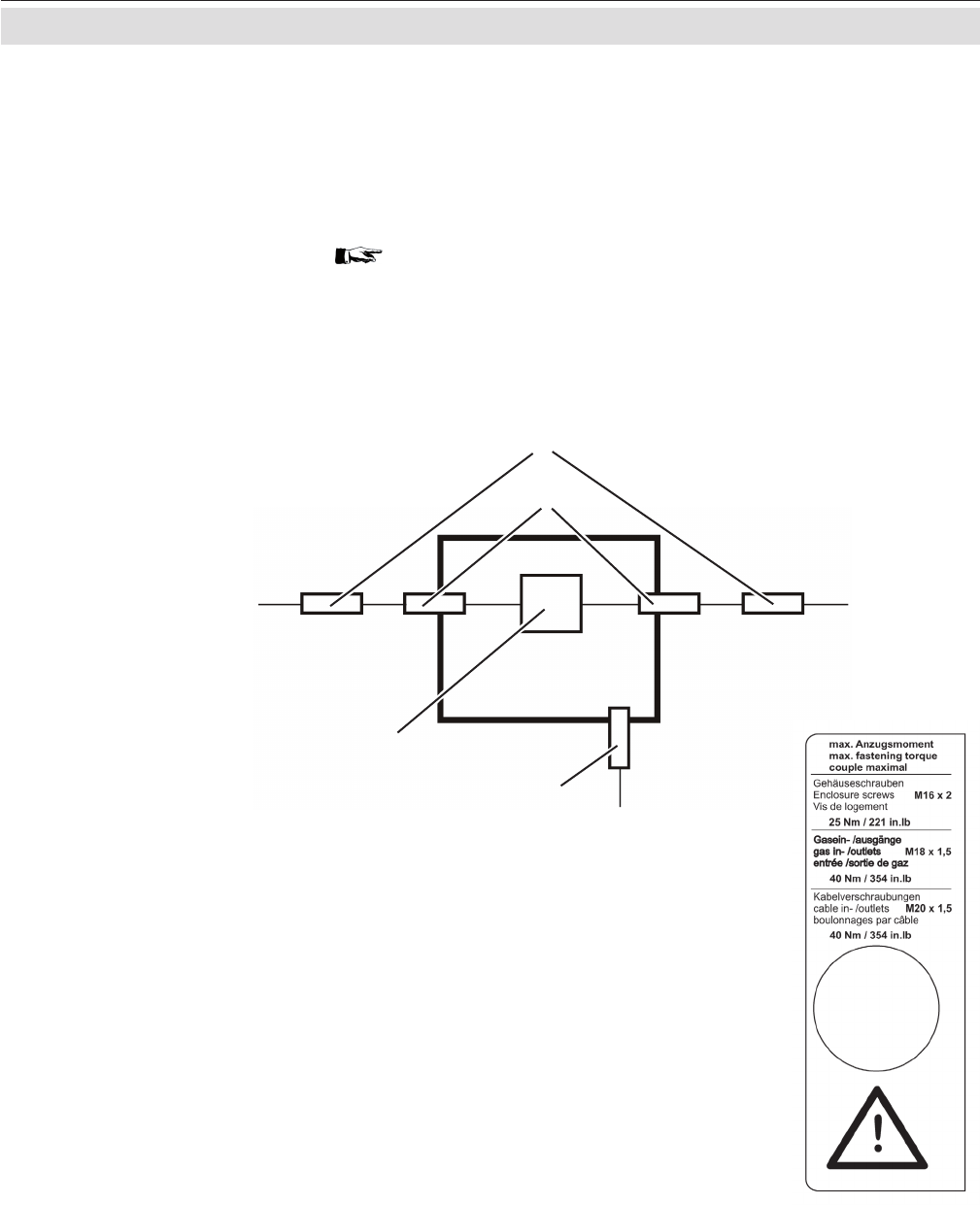

2.3.1.3 Fastening Torques for Enclosure Components

1

4

2

3

1: Flame arrestors for gas path

2: Measuring system

3: Flame arrestor as breathing device

4: External ame arrestors, approved

for higher pressure

Fig. 2-6: Exemplary diagram for a single channel

instrument for high gas pressure

Fig. 2-7: Label with fastening torques,

installed at the instrument

Consider the permitted fastening torques,

when installing components to the enclosure,

as given on a label at the instrument!