Operation Using

Automatic Display M odule (ADM)

Flush the System

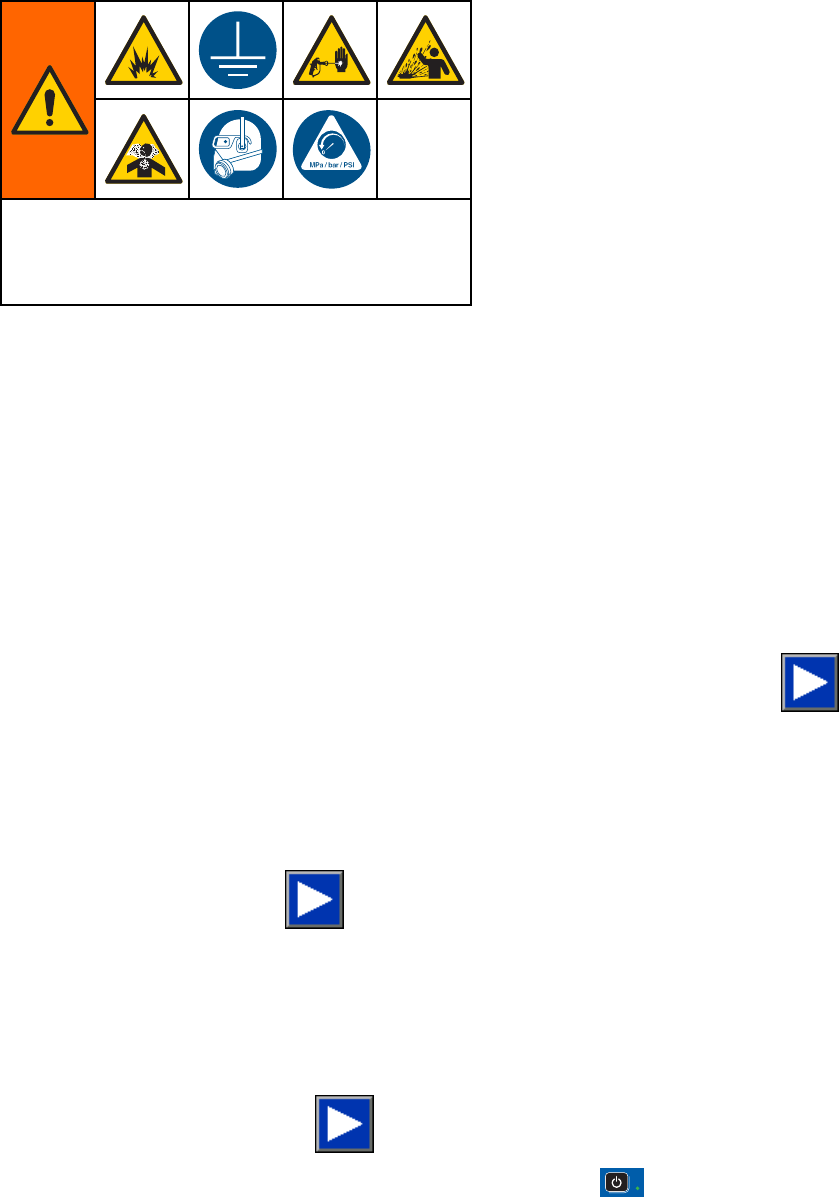

To avoid fire and explosion, always ground

equipment and waste container. To avoid injury

from splashing, always flush at lowest possible

pressure.

Follow this procedure before:

• the first time material is loaded into the equipment

•servicing

• shutting down equipment for an extended period

of time

• putting equipment into storage

Single Color System

1. Relieve the pressure. See

Pressure Relief Procedure, page 19.

2. Disconnect the color and catalyst supply lines

from the pump inlet manifolds, and connect

regulated solvent supply lines.

3. Set the solvent supply pressure regulator at the

lowest pressure possible. Generally a setting

of 25–50 psi (0.18–0.35 MPa, 1.8–3.5 bar) is

sufficient.

4. Enable manual override on

System Screen 5, page 71.

5. On the ADM, go to the Fill screen. Set the

Material to Color (A). Press

. The system

will pump solvent through pump A all the way to

the gun.

6. Hold a metal part of the spray device firmly to a

grounded metal pail. Trigger the spray device

until clean solvent dispenses.

7. On the ADM, go to the Fill screen. Set the

Material to Catalyst (B). Press

.The

system will pump solvent through pump B all the

way to the gun.

8. Relieve the pressure. See

Pressure Relief Procedure, page 19

Color Change S

ystem

1. Relieve the pressure. See

Pressure Relief Procedure, page 19.

2. Attach regulated solvent supply lines as follows:

• Multiple color/single catalyst system: On the

color side, do not disconnect the color supply

line from the inlet manifold of Pump A. Instead,

connect a regulated solvent supply line to the

designated solvent valve on the color valve

manifold. On the catalyst side, disconnect

the catalyst supply line from the inlet manifold

of Pump B, and connect a regulated solvent

supply line.

• Multiple color/multiple catalyst system:

Connect regulated solvent supply lines to

the designated solvent valves on the color

and catalyst valve manifolds. Do not connect

solvent supply lines directly to the inlet

manifolds of the pumps.

3. Set the solvent supply pressure regulator at the

lowest pressure possible. Generally a setting

of 25–50 psi (0.18–0.35 MPa, 1.8–3.5 bar) is

sufficient.

4. On the ADM, go to the Fill screen. Set the

Material to Solvent. Press

. The system

will pump solvent from the color valve inlet all the

way to the gun.

5. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until clean solvent

dispenses.

6. Repeat for each color line.

7. Relieve the pressure. See

Pressure Relief Procedure, page 19

Shut

down

1. Flush out the mixed material to avoid potlife errors

and fluid setup in the lines. See Purging, page 22.

2. Follow the Pressure Relief Procedure, page 19.

3. Close the main air shutoff valve on the air supply

line and on the control box.

4. Press

on the Display Module to turn off

power to the pumps.

5. Shut off system power (0 position).

332564B 23