Operation Using

a Programmable Logic Controller (PLC)

OUTPUT REGISTERS 01, 02, 03, and 04: Pump

Status

ThePumpStatu

s registers contain a number that

indicates the

state of Pumps 1 — 4. This status can

be used for gen

eral monitoring of the pump state,

or as an indica

tor for driving independent pump

operations.

See INPUT REGISTER 02: Flush/Prime

Pump Command

, page 36.

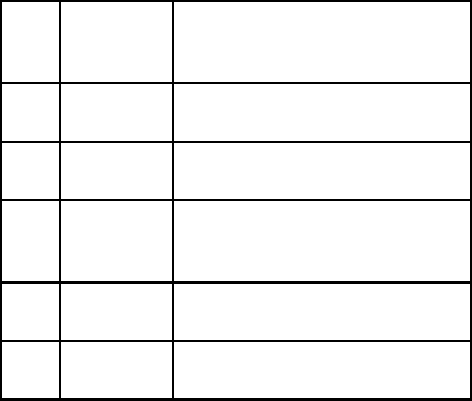

Table4PumpS

tates for Output Registers 01–04

Nu-

m-

ber

Pump

State

Description

0

Off

The pump is powered down or

not enabled.

1

Standby

The pump is powered but not

currently active.

2 Busy The pump i

s currently in

arecipec

hange or mixing

operatio

n.

3 Flushing

The pump is currently flushing

with solvent

4 Priming The pump

is currently priming

with mat

erial.

OUTPUT REGISTER 05: Actual Mix Flow

The Act

ual Mix Flow register reports back the

insta

ntaneous mixing flow rate in cc/min.

NOTE: This register is valid only during a mix

operation.

OUTPUT REGISTER 06: Actual Mix Ratio

The A

ctual Mix Ratio register contains the

inst

antaneous calculated mix ratio.

• The value reported is the ratio antecedent

multiplied by 100. The ratio consequent is always

1.

Example

: Value = 250 >> A mix ratio of 2.5:1

(Material A to Material B)

•Ift

he current recipe ratio is 0:1 (1K recipe) this

va

lue will be 0.

This register is valid only during a mix operation.

OUTPUT REGISTER 07: Actual Mix Potlife

Remaining

The Actual Pot

life Remaining register contains

the current am

ount of time remaining in the active

recipe’s potl

ife in seconds.

NOTE: If potlife is disabled for the active recipe or at

initial startup this value will be 0xFFFFFFFF.

OUTPUT REGISTER 08: Active Recipe Number

TheActiveR

ecipe Number register contains the

number of th

eactiverecipe(1–60).

• This value is 0 if the system was flushed.

• This value is 61 if the system does not know the

current loaded recipe, if the recipe is invalid, or at

initial startup.

OUTPUT REGISTER 09: Active Recipe Material A

The Activ

e Recipe Material A register contains the

number of

the Color (1 – 30) that is associated with

the curre

nt recipe.

• This value is 0 if the system was flushed.

• This value is 61 if the current recipe is invalid or at

initial startup.

OUTPUT REGISTER 10: Active Recipe Material B

The Act

ive Recipe Material B data register contains

the num

ber of the Catalyst (31 – 34) that is associated

with t

he current recipe.

• This value is 0 if the system was flushed.

• This value is 61 if the current recipe is invalid or at

initial startup.

• This value is 0 if the current recipe ratio is 0:1 (1K

recipe).

OUTPUT REGISTER 11: Active Recipe Material A

Flush Sequence

The

Active Recipe Material A Flush Sequence

reg

ister contains the number of the Flush Sequence

(1 –

5) that is associated with the Color pump of the

cur

rent recipe.

If the current recipe is invalid this value reflects the

Flush Sequence associated with Material A pump

of recipe 0.

332564B 29