Operation Using

a Programmable Logic Controller (PLC)

ProMix PD2K Network Inputs

The ProMix PD2K Network Inputs are Write-Read capable, but should be treated as outputs from a PLC or

other networking device. These registers allow the user to control system operation and configure system

settings remotely. Invalid values (i.e. out of bounds or not consistent with system configuration) will be ignored

by the ProMix PD2K. All values must be written as integers. Floating point numbers are not supported.

Do not rely on

these registers for Read status, other than to confirm data that has been written and accepted.

NOTE: The PD2K system does not refresh the values for these registers. At power up all input registers

initialize to invalid values.

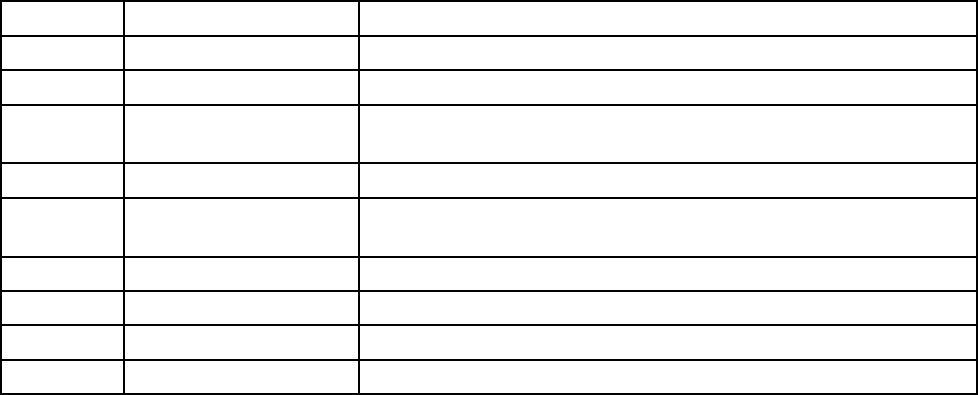

INPUT REGISTER 00: System Mode Command

The System M

ode Command register accepts a number that represents a command to the PD2K system

to initiate

a particular operation. Some operation modes may be initiated only under certain conditions (see

Figures 5 –

9 for details).

Number

Operation Mode

Descripti

on

1

No OP

The system takes no action.

2 Power Pumps

The system powers on or powers off the pumps.

3

Remote Stop The system stops all current operations and turns off power to the

pumps.

4

Recipe

Change

The sys

tem initiates a recipe change. (See also Register 7.)

5

Mix Fill

The system fills the mix manifold and gun with material at ratio for

a valid recipe.

6Mix Thesy

stem initiates a mix/spray cycle.

7

Purge A The system purges only Material A out through the gun.

8 Purge B The system purges only Material B out through the gun.

9

Standby The system puts all active pumps into Standby mode.

36 332564B