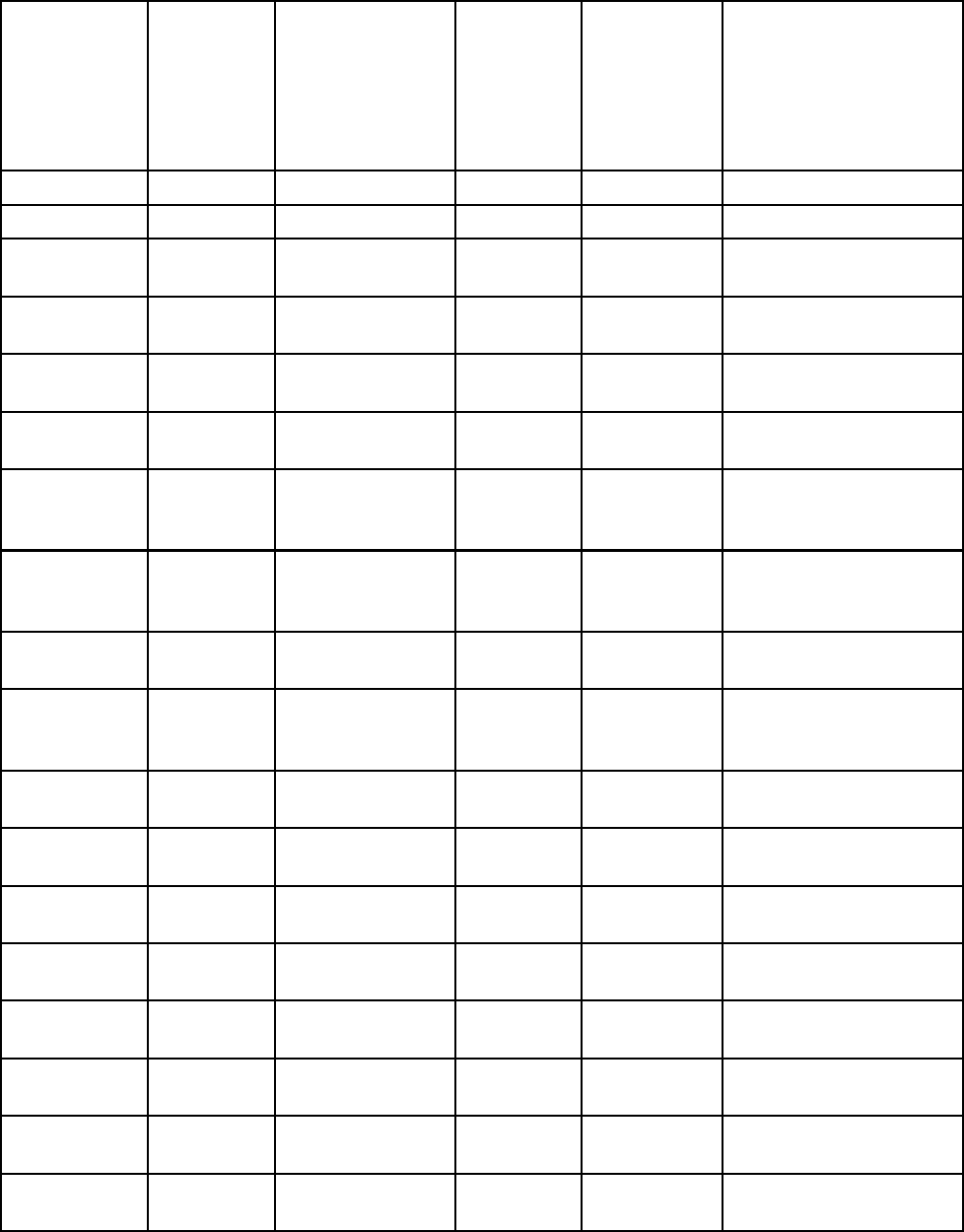

Operation Using

a Programmable Logic Controller (PLC)

0=Off

1 = Standby

2=Busy

3 = Flushing

04 40108

Pump 4 Status

uint32

NONE

4 = Priming

05 40110 Actual Mix Flow uint32 cc/min 1 - 1600

06 40112 Actual Mix Ratio uint32

NONE

0 - 5000

07 40114

Actual Mix Potlife

Remaining

uint32

sec

0 – 59940

08 40116 Active Re

cipe

Number

uint32

NONE

0-61

09 40118 Active Recipe

Material A

uint32

NONE

1-30,61

10 40120 Active Recipe

Material B

uint32

NONE

31 - 34, 61

11 40122 Active

Recipe

Materi

al A Flush

Sequen

ce

uint32

NONE

1-5

12 40124 Active Recipe

Material B Flush

Sequence

uint32

NONE

1-5

13 40126 Active Recipe

Ratio Set Point

uint32

NONE

0 - 5000

14 4012

8

Acti

ve Recipe

Potl

ife Time Set

Poin

t

uint

32

min 0 - 99

9

15 40130 Actual Pump 1

Flow Rate

uint32 cc/min 0 - 800

16 40132 Actual Pump 2

Flow Rate

uint32 cc/min 0 - 800

17 40

134

Ac

tual Pump 3

Fl

ow Rate

ui

nt32

cc

/min

0-

800

18 40136 Actual Pump 4

Flow Rate

uint32 cc/min 0 - 800

19 40138 Actual Pump 1

Fluid Pressure

uint32

P

SI

0 - 1500

2

0

4

0140

A

ctual Pump 2

Fluid Pressure

u

int32

PSI

0

-1500

21 40142 Actual Pump 3

Fluid Pressure

uint32

PSI

0 - 1500

22 40144 Actual Pump 4

Fluid Pressure

uint32

PSI

0 - 1500

34 332564B