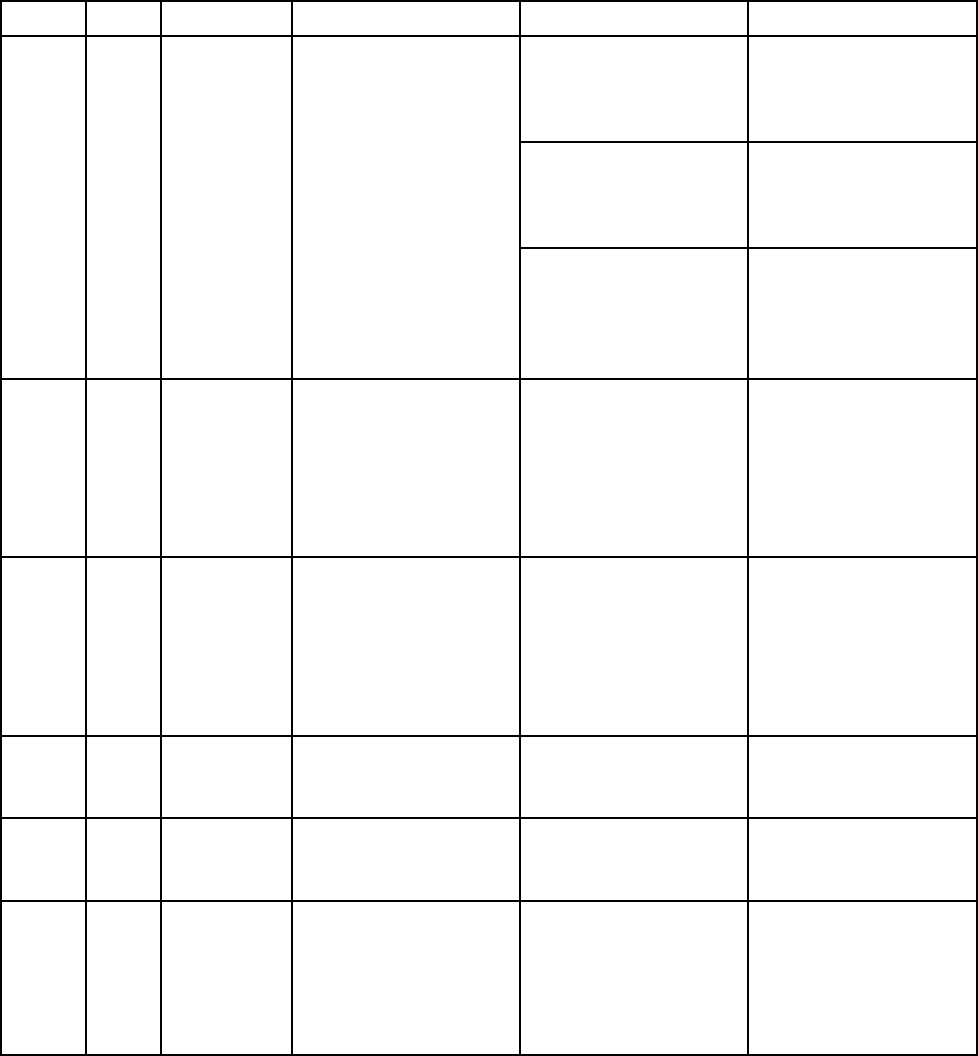

System E rrors

Code

Type Description Problem

Cause Solution

There is a restriction on

the outlet side of the

pump or color stack.

Make sure there are no

restrictions in the color

stack and that the dump

valve is actuating.

Thick viscos

ity paint

requires mor

e pressure

to pump.

Increase non

-mix

pressure if n

ecessary

to create flow

during

the fill funct

ion.

F1F#

Alarm Flow Low

Fill Pump #

There has been

no flow

or low flow duri

ng a

pump fill opera

tion.

The pumps do not

have to move for the

system to build enough

pressure to meet the

setpoint.

Increase non-mix

pressure if necessary

to create flow during

the fill function.

F1S#

Alarm Flow Low

Purge Pump

#

There has b

eennoflow

or low flow

during a

pump purg

e operation.

Restriction in the outlet

side of the pump or

color stack resulting in

the solvent flow being

too low.

Make sure there are

no restrictions in the

system. Increase

non-mix pressure if

necessary to create

flow during the purge

function.

F7D#

Alarm Flow

Detecte

d

Pump #

Thepumpflow

exceeded 20 cc/min

flowcomingintoIdle

mode.

There is

a leak in the

system o

r the gun was

open whe

n the system

went in

to Idle mode.

Verify there are no

leaks in the system.

Make sure the air flow

switch is actuating

properly. Do not

trigger the gun without

atomizing air.

F8D1 Alarm Flow Not

Detected

No flow

while mixing.

Restriction in the outlet

side of the pump or

color stack.

Make sure there are

no restrictions in the

system.

F9D#

Alarm Flow

Unst

able

Pump

#

Thepumpflowrate

did not stabilize while

entering Idle mode.

Poten

tial leak in the

syst

em.

Check the system for

leaks and run manual

stall test.

SAD

1

Alarm Atomizing

Solvent

Air

flow switch is

act

ive while solvent,

dil

uted material, or an

unk

nown material is in

the

gun.

Atomizing air supply

was not shut off before

purging or filling spray

gun.

Make sure atomizing

air is shut off before

purging or filling the

spray gun. Use an

AA cutoff valve on the

atomizing air supply.

92 332564B