Operation Using

a Programmable Logic Controller (PLC)

Operation Usi

ng a Programmable Logic Controller

(PLC)

Network Communications and

Discrete I/O

The ProMix PD2K Automatic system does not use

a Booth Control module. Instead, it uses Network

Communications and has optional Discrete I/O

features to drive the system remotely.

Some automation control elements of the

ProMix PD2K can be driven by a discrete

input

or

network communications. These

options need to be configured at the ADM (see

System Screen 5, page 71). The following features

can be set to ‘Discrete’ or ‘Network’:

• Flow Cont

rol – Means of adjusting the control set

point (s

ee Flow Control Set Point below).

• Gun Trig

ger – Means of signaling the ProMix PD2K

when the

spray device is triggered.

NOTE: Th

e Manual Override check box enables a

user to

operate the system before the automation

(PLC) i

s available. Manual Override can be used to

run all

functions of the system if a proper gun trigger

signal

is provided. It is not intended to be the main

mode of

control. Graco recommends that Manual

Overri

de be disabled during normal operation to

avoid

driving the system in a way that conflicts with

the au

tomation sequence.

Discrete I/O

The ProMix PD

2K does not supply power for

Discrete I/

O. A clear understanding of these inputs

is necessar

y to properly integrate the ProMix PD2K

with the PLC

or networking device. Input and output

connection

s are made at the Discrete I/O terminal

strips on t

he Enhanced Fluid Control Module (EFCM)

inside the

control box.

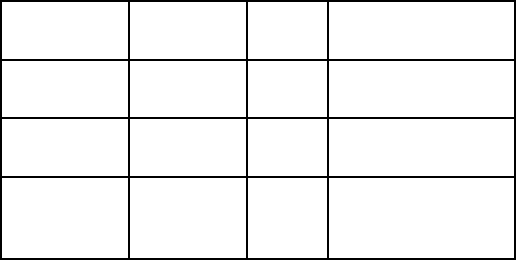

Table 3 and Figure 2 show where discrete I/O

connections are made on the ProMix PD2K.

Table 3 PD2K Discrete I/O Connections

I/O

Description

EFCM

Connector

Pins Type

Gun Trigger

Input

61,2

Normally Open

Contact

Contro

lSet

Point

7

1,2 4-20 mA Input

Safety

Interlock

Input

7

11,12

Normally Open

Contact

2

4

332564B