Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTPUT CONNECTIONS

ELECTRIC SHOCK can kill.

• Keep the electrode holder, TIG

torch and cables insulation in

good condition and in place.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and ground.

• Turn the power off pushbutton on the Square Wave

TIG 355 “off” before connecting or disconnecting

output cables or other equipment.

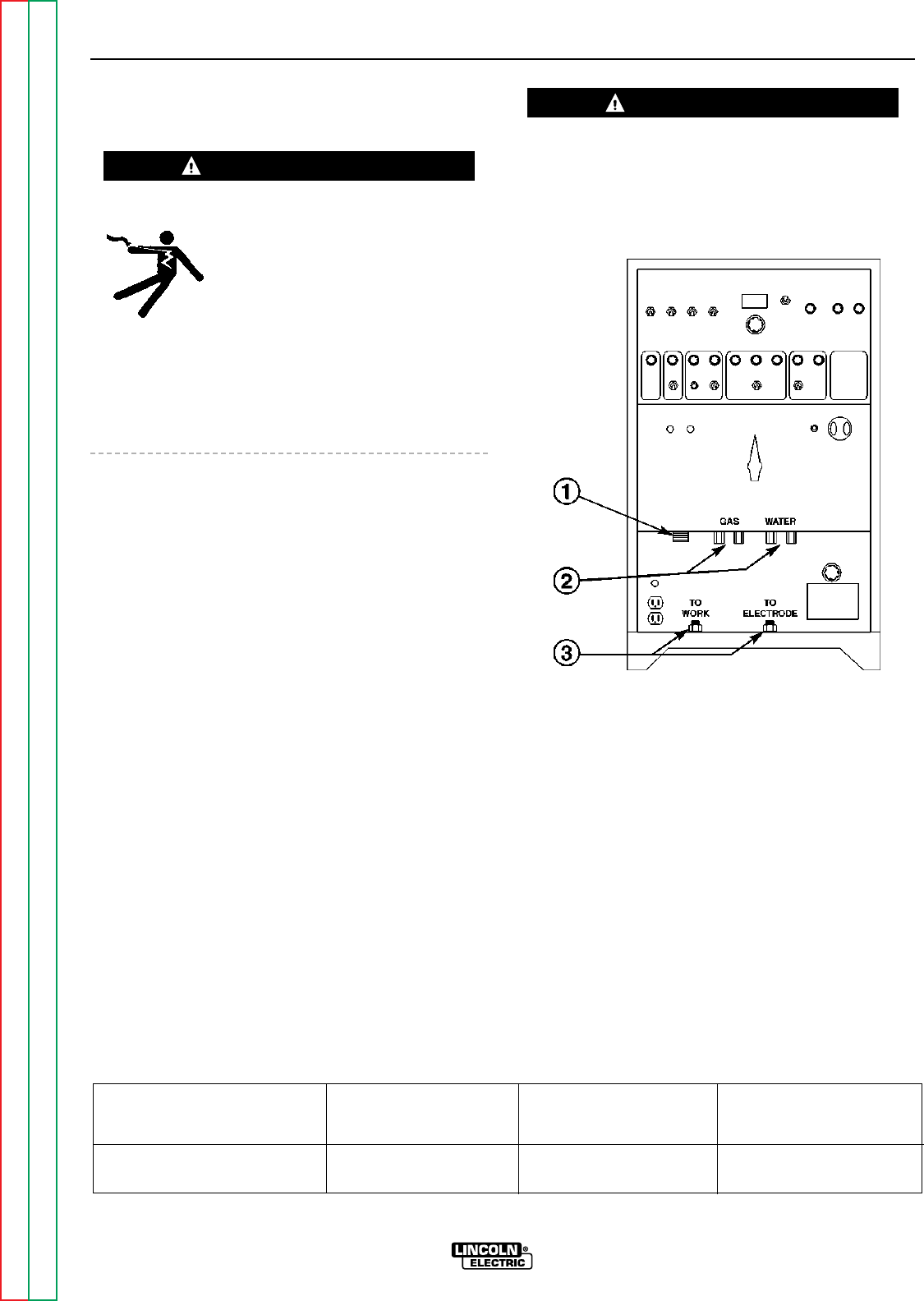

See Figure A.3 for the location of the work and elec-

trode terminals, the gas and optional water solenoids,

and the Remote Receptacle.

TIG TORCH CONNECTION

TIG welding torches come with 15 ft (4.6m) and 25 ft

(7.6m) cables. Use the shorter length whenever pos-

sible to minimize possible radio interference problems.

With power source off, connect the torch cable to the

“Electrode” terminal on the welder. Connect a sepa-

rate work cable to the “Work” terminal of the welder.

See Table A.3 for recommended work cable sizes.

Both work and electrode cables should be routed

through the cable strain relief holes provided in the

base directly below the welding ouput terminals.

Connect the TIG torch gas and water fittings to the

welder fittings. any torch with fittings that conform to

Compressed Gas Association (CGA) standards can be

used.

The welder fittings have the following threads: Gas

Inlet and Outlet: 5/8”-18 right-hand female; Water inlet

and Outlet: 5/8”-18 left-hand female. The cylinder of

inert shielding gas must be equipped with a pressure

regulator and flow meter. Install a hose between the

flow meter and gas inlet on the welder.

Observe the safety precautions necessary for handling

and using compressed gas containers. Contact your

supplier for specific information.

INSTALLATION

A-7 A-7

SQUARE WAVE TIG 355

1. REMOTE RECEPTACLE

2. WATER AND GAS

SOLENOIDS

3. WORK (LEFT) AND

ELECTRODE TERMINALS

WARNING

WARNING

TABLE A.3

CABLE SIZES FOR COMBINED LENGTHS OF COPPER ELECTRODE AND WORK CABLE

Lengths up to 100 to 200 ft 200 to 250 ft

Machine Size 100 ft (30 m) (30 to 61 m) (61 to 76 m)

350 Amp

40% Duty Cycle #1 (45mm

2

) 1/0 (55mm

2

) 2/0 (70mm

2

)

FIGURE A.3 – FRONT PANEL