Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-81 F-81

TROUBLESHOOTING & REPAIR

SQUARE WAVE TIG 355

5) Re-inspect the SCR for proper

seating.

6) Clamp the cap screws. Use the

procedure for 1/4-28 cap screws

or 1/4-20 bolts, depending on

which you have.

Clamping procedure for 1/4-28 cap

screws.

NOTE: This procedure can only be

used with 1/4-28 bolts. Do not use

bolts with any other type thread, or the

new SCR will be damaged. Do not

overtighten the cap screws. The leaf

spring will apply the required clamping

force to the SCR.

a. Do not turn the nuts. While

holding the nuts stationary,

turn the bolts only with the fol-

lowing procedure.

b. Tighten first cap screw 1/4

turn.

c. Tighten second cap screw 1/2

turn.

d. Tighten first cap screw 1/2

turn.

e. Tighten second cap screw 1/2

turn.

f. Tighten first cap screw 1/4

turn. Stop. The assembly

now has proper clamping

force.

Clamping procedure for 1/4-20 cap screws.

NOTE: This procedure can only be used

with 1/4-20 cap screws. Do not

use cap screws with any other

type thread, or the new SCR will

be damaged. Do not overtighten

the cap screws. The leaf spring

will apply the required clamping

force to the SCR.

a. Do not turn the nuts. While

holding the nuts stationary,

turn the cap screws only with

the following procedure.

b. Tighten first cap screw 1/4

turn.

c. Tighten second cap screw 1/2

turn.

d. Tighten first cap screw 1/2

turn.

e. Tighten second cap screw 1/4

turn. Stop. The assembly

now has the proper clamping

force.

7) Perform the Active SCR Test.

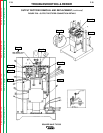

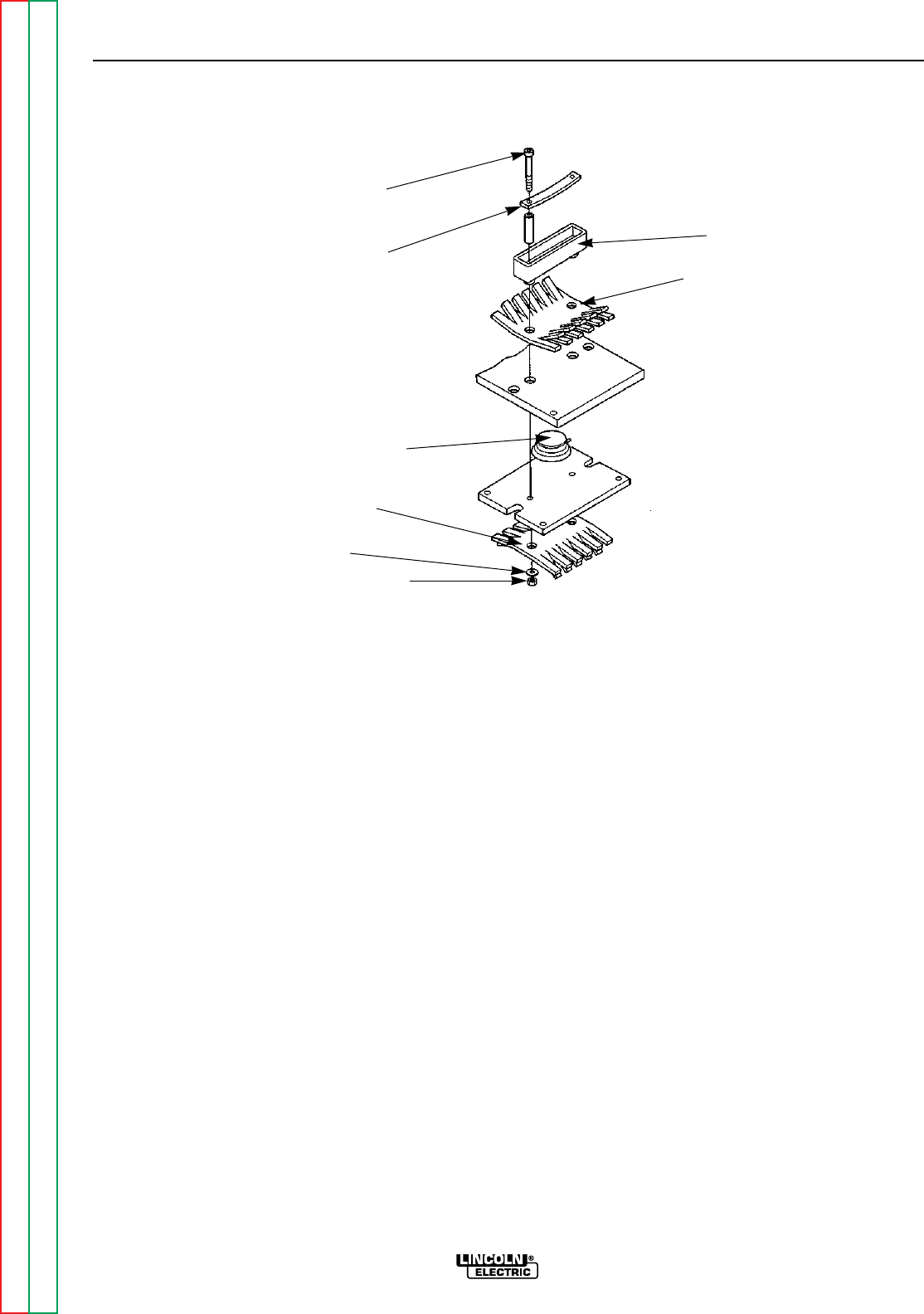

FIGURE F.29 – SCR CLAMP ASSEMBLY DETAILS – 1/2” WIDE SPRING

SCR REMOVAL AND AND REPLACEMENT (continued)

Plastic Housing

Cap Screw

Leaf Spring

Heat Sink

SCR

Heat Sink

Plain Washer

Clamp Nut