Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-16 F-16

SQUARE WAVE TIG 355

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.

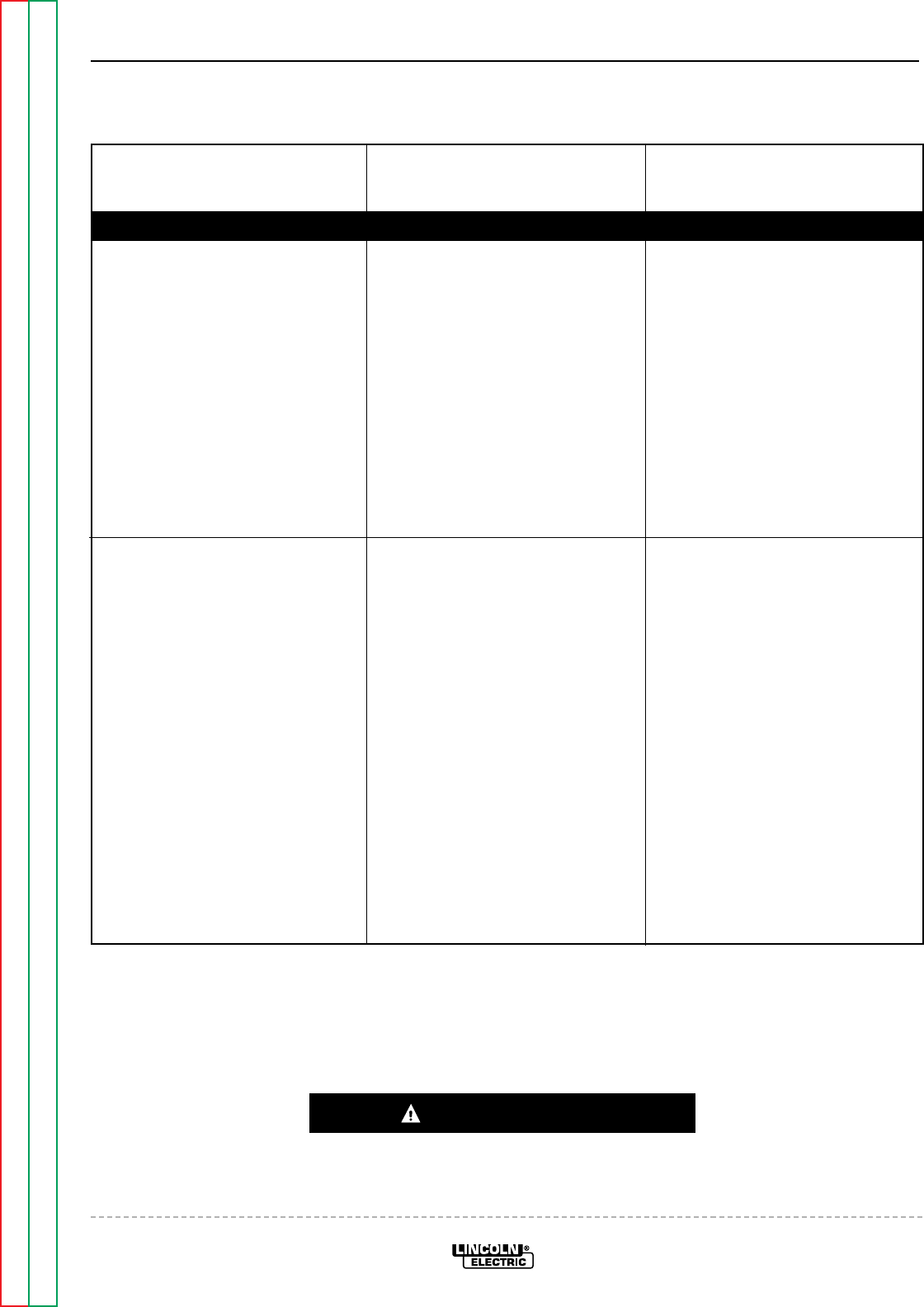

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

TIG MODE PROBLEMS

The machine output is intermit-

tently lost. Gas flow and high fre-

quency are also interrupted.

1. The problem may be caused

by high frequency inteference.

Make sure that the machine is

grounded properly according

to the installation instructions.

If there are other high frequen-

cy sources in the area, make

certain they are grounded

properly.

2. Check the Arc Start switch or

Amptrol for proper operation

and loose connections.

1. The machine internal ground

connections may be loose.

Check the mounting screws on

the protection board, the

bypass boards, and the feed-

thru board.

2. The protection or bypass

boards may be faulty. Check

or replace.

3. Perform the Arc Start Trigger

Circuit Test.

The arc “flutters” when TIG weld-

ing.

1. The tungsten electrode may be

too large in diameter.

2. The tungsten electrode may

needed sharpening.

3. If helium shielding gas is used,

reduce the percentaghe of heli-

um.

4. Adjust the gas flow rate to the

proper level for the process

being used.

5. Check gas hoses and connec-

tions for leaks.

1. Check for loose shunt connec-

tions, leads #222 and #221.

See Wiring Diagram.

2. Check polarity switch for loose

or faulty connections.

3. Perform the SCR Rectifier

Bridge Tests.

4. Check components R6 and C6

in the high voltage transformer

primary circuit. Replace if nec-

essary.

5. The control board may be

faulty. Replace.

6. The power board may be

faulty. Replace.