Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

THEORY OF OPERATION

E-6 E-6

SQUARE WAVE TIG 355

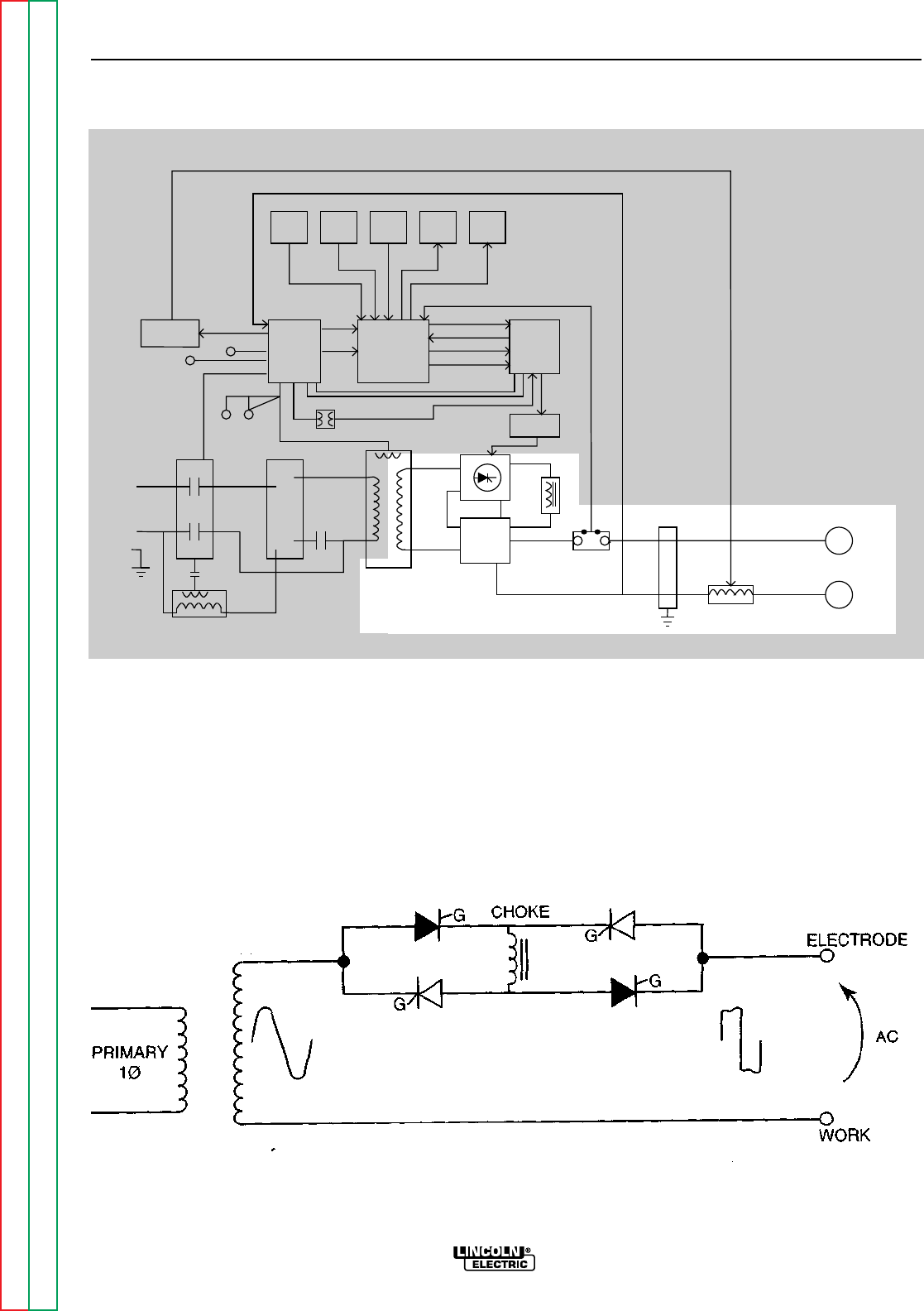

AC WELDING OUTPUT

Rotating the polarity switch to the AC position

changes the welding power circuit. One lead (X2) of

the main transformer secondary is connected to the

machine output work terminal. The other secondary

lead (X1) is connected to one of the AC connections

on the SCR bridge. The electrode terminal is con-

nected to the other AC side of the bridge. The choke

is now electrically across the negative and positive

SCR bridge connections. With the ability of the choke

to store energy and the SCRs to turn on at the appro-

priate times, an AC square wave is developed and

applied to the output terminals.

FIGURE E.6 – AC WELDING OUTPUT CIRCUIT

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

HIGH VOLTAGE

TRANSFORMER

CIRCUIT

REMOTE

RECEPTACLE

GAS/WATER

SOLENOIDS

FANS

115VAC

RECEPTACLE

INPUT

CONTACTOR

R

E

C

O

N

N

E

C

T

POWER

FACTOR

CAPACITORS

FEED - THRU

BOARD

CONTROL

BOARD

POWER

BOARD

SNUBBER

BOARD

MAIN

TRANSFORMER

AC

AC

DC-

DC+

POLARITY

SWITCH

SHUNT

C

H

O

K

E

BY-PASS

BOARDS

WORK

ELECTRODE

HI-FREQ

TRANSFORMER

PILOT

TRANSFORMER

START/

STOP

PANEL

SWITCHES

UPPER

CONTROL

PANEL

LOWER

CONTROL

PANEL

DISPLAY

BOARD

STATUS

BOARD

ELECTRODE SENSE

HIGH FREQUENCY SPARK

115VAC

INTERLOCK

HI-FREQ AND GAS/WATER

115VAC -

115VAC

CONTROL TRANSFORMER

INTERLOCK

ELECTRODE

SENSE

REMOTE

COMMANDS

GATE COMMANDS

HI-FREQ/

WATER/GAS

COMMANDS

INTERLOCK

115VAC

SCR

TRIGGER

15VDC

115VAC

FIGURE E.6a – SCR BRIDGE AND CHOKE CONFIGURATION FOR AC WELDING

X1

X2