Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-50 F-50

CONTROL PC BOARD TEST (continued)

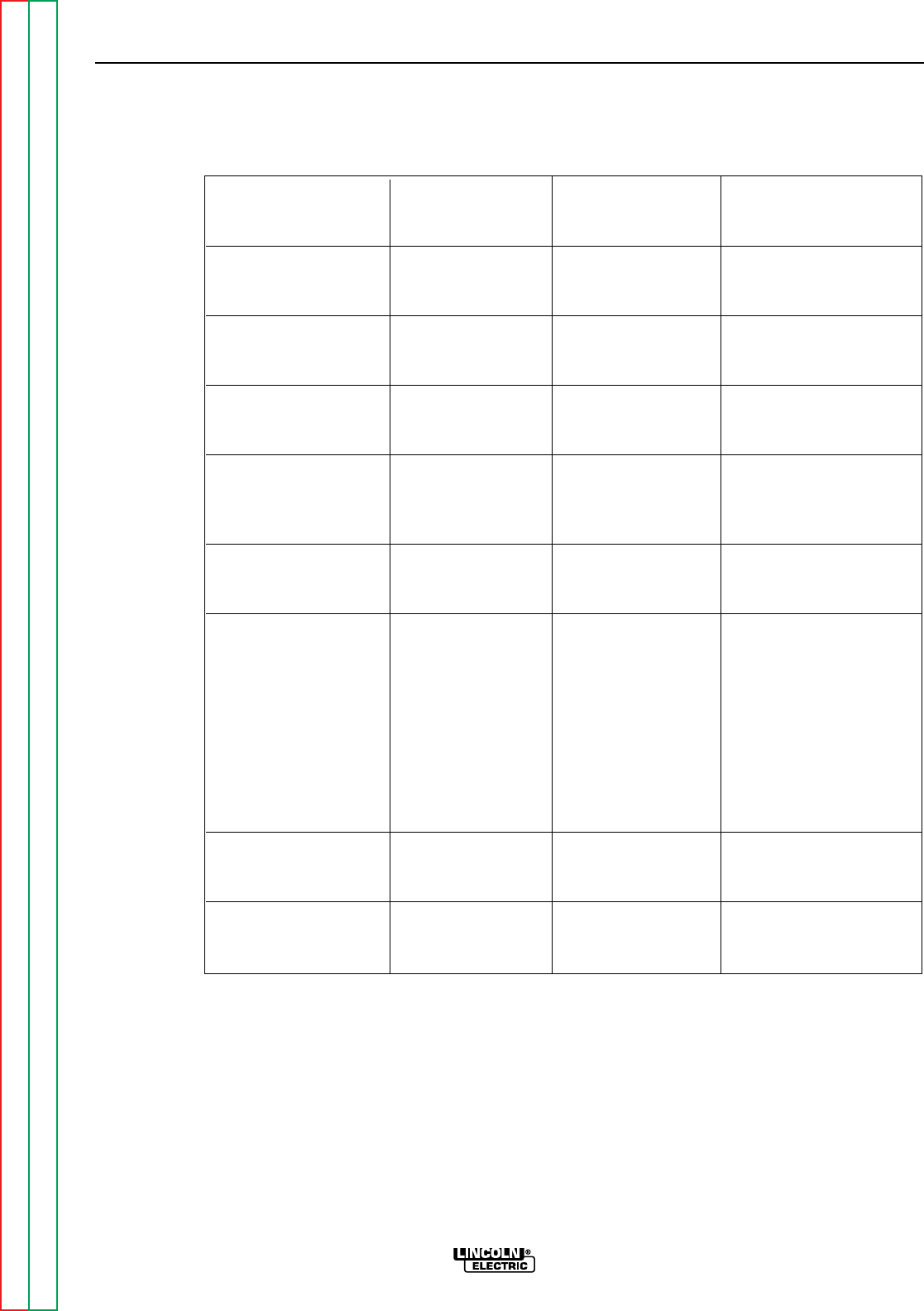

CONTROL PC BOARD VOLTAGE TEST POINTS CHART

TROUBLESHOOTING & REPAIR

SQUARE WAVE TIG 355

Special

Signals Being Expected Conditions

Test Points Checked Reading for Test

3J13 to 5J13 Regulated +15VDC +15VDC None

supply to control

board

4J13 to 5J13 Regulated -15VDC -15VDC None

supply to control

board

1J13 to 2J13 Unregulated DC +12VDC None

supply to control

board

R11 to 5J13 Low logic signal for 0 - 2 VDC TIG Mode

gas/water valve Arc Start Switch or

Amptrol must be

activated

R32 to 5J13 Low logic signal for 0 - 2 VDC If input contactor is

interlock control staying closed signal

will normally be low.

R13 to 5J13 Low logic signal 0 - 2 VDC CAUTION: High

for high frequency frequency may

damage test

equipment.

Use analog

volt/ohmmeter

TIG Mode

High frequency is

active after gas

preflow time.

R66 to 5J13 Low logic signal for 0 - 2 VDC StickMode

DC OCV Boost DC Mode

(CR3) relay

R8 to 5J13 Low logic signal for 0 - 2 VDC Stick Mode

AC OCV Boost AC Mode

(CR2) relay