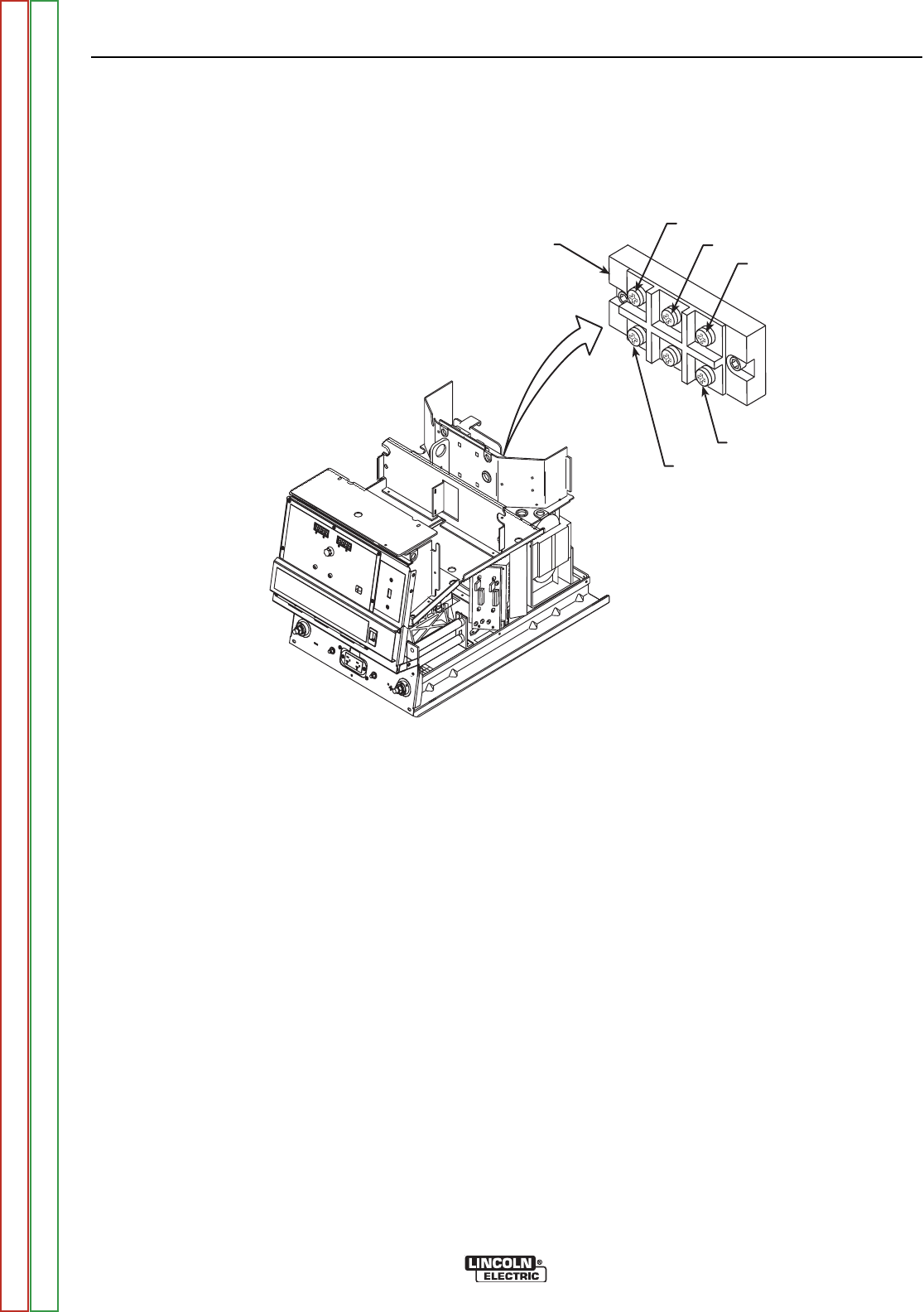

FIGURE F.17 – INPUT RECTIFIER LOCATION

INPUT RECTIFIER

REMOVAL AND REPLACEMENT PROCEDURE (continued)

REMOVAL PROCEDURE

1. Remove input power to the V450-PRO.

2. Using the 3/8” nut driver, remove the case top,

input access panel and sides.

3. Perform the Capacitor Discharge Procedure.

4. Locate and remove the RTV sealant from the

input rectifier connection terminals. See Figure

F.17.

5. Label and, using the Phillips head screwdriver,

carefully remove the five leads from the input

rectifier terminals. Note placement for

reassembly. See Figure F.17.

6. Using the 3/16” allen wrench, remove the two

mounting screws and washers from the rectifier

module.

7. Carefully remove the input rectifier module.

REPLACEMENT PROCEDURE

1. Clean heat sink surfaces.

2. Apply an even coating of joint compound

(Penetrox A-13) to both the heat sink and mod-

ule mounting surfaces. The joint compound

should be 0.002 - 0.005 in. thick per surface.

3. Mount the module to the heat sink and evenly

torque the mounting screws (with washers) to

44 in/lbs.

4. Assemble the leads to the correct module ter-

minals and torque to 26 in/lbs. See Figure F.17.

5. Apply RTV sealant to the rectifier connection

terminals.

6. Install the case top, sides, and input access

panel using the 3/8” nut driver.

TROUBLESHOOTING AND REPAIR

F-64 F-64

INVERTEC® V450-PRO

NEG (-)

POS (+)

A

B

C

I

NPUT

RECTIFIER

NEG (-)

POS (+)

A

B

C

I

NPUT

RECTIFIER

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC