THEORY OF OPERATION

E-2 E-2

INVERTEC® V450-PRO

POWER SOURCE

GENERAL DESCRIPTION

The INVERTEC® V450-PRO is an inverter based

welding power source that is designed to be a multi-

process welding system. It is a high performance, dig-

itally controlled inverter capable of complex, high-

speed waveform control. With the appropriate modu-

lar components it can support constant current, con-

stant voltage and pulse welding processes. The output

rating is 450 amps at 36 volts with a 100% duty cycle.

INPUT VOLTAGE AND

PRECHARGE

The INVERTEC® V450-PRO can be connected for a

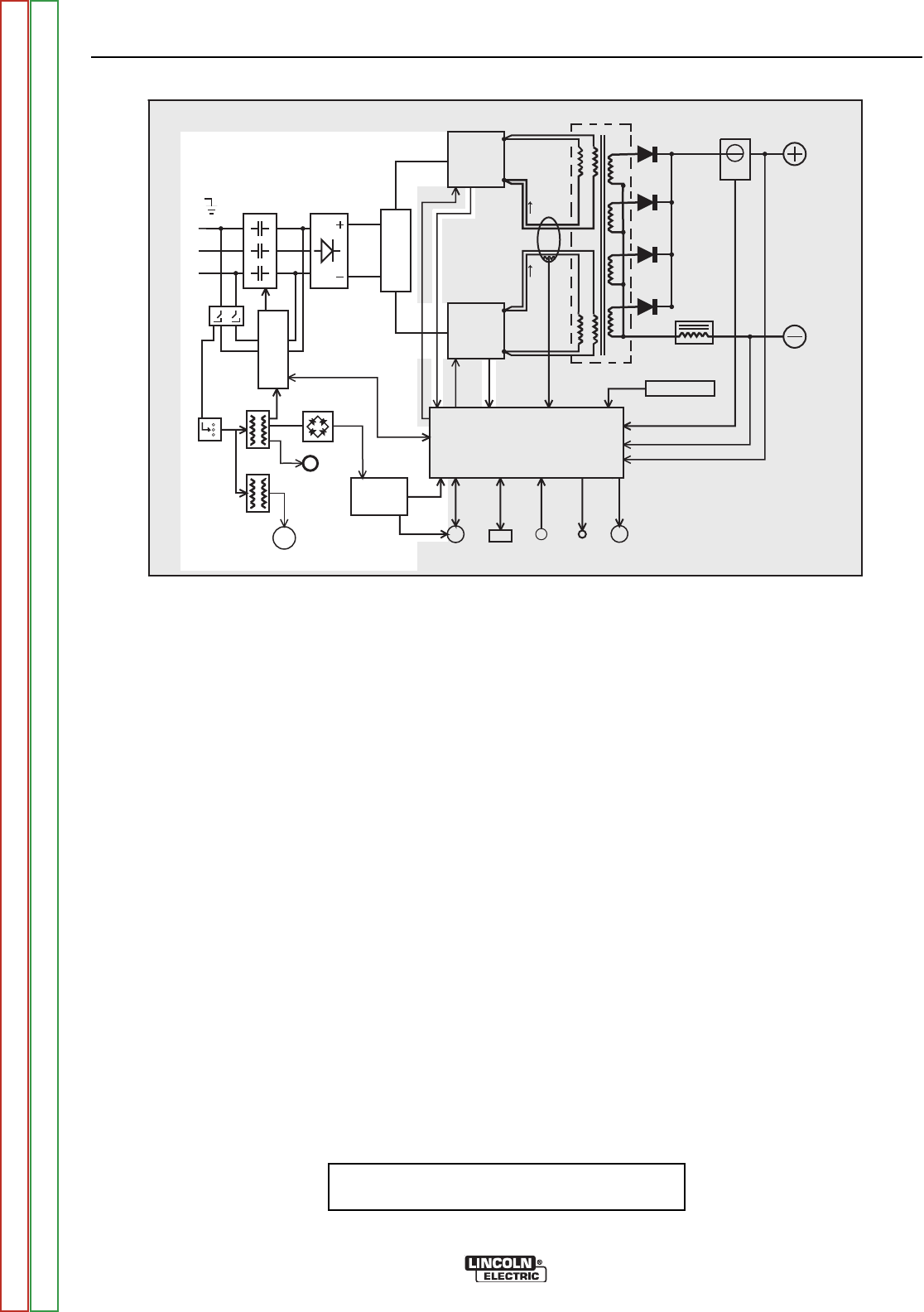

variety of three phase voltages. Refer to Figure E.2.

The initial input power is applied to the INVERTEC®

V450-PRO through a line switch located on the front of

the machine. Two phases of the three-phase input

power is applied to the input board and both auxiliary

transformers. The various secondary voltages devel-

oped by the #1 auxiliary transformer are applied to the

input board, the power board rectifier and the fan

motor. The 115 VAC secondary voltage developed by

the No. 2 auxiliary transformer is applied to the 115

VAC receptacle.

FIGURE E.2 - INPUT VOLTAGE AND PRECHARGE.

The 65 VDC produced from the power board rectifier is

utilized by the power board to provide various DC volt-

ages for the control board and wire feeder.

The two phases, which are connected to the input

board through the power switch, are connected to the

input rectifier. During precharge or “soft start” these

two phases are current limited by the input board. This

AC input voltage is rectified, and the resultant DC volt-

age is applied through the reconnect switches to the

input capacitors located on the switch boards. The

control board monitors the voltage across the capaci-

tors. When the capacitors have charged to an accept-

able level, the control board signals the input board to

energize the main input contactor making all three

phases of input power, without current limiting, avail-

able to the input capacitors. At this point, the

INVERTEC® V450-PRO is in the “Run Mode” of oper-

ation. If the capacitors become under or overvoltage,

the control board will signal the input board to de-

energize the main input contactor, and the

INVERTEC® V450-PRO will be disabled.

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

INPUT

CONTACTOR

INPUT

RECTIFIER

R

E

C

O

N

N

E

C

T

CONTROL BOARD

R

IGHT

SWITCH

BOARD

L

EFT

SWITCH

BOARD

M

AIN

TRANSFORMER

CURRENT

S

ENSOR

CHOKE

OUTPUT

TERMINAL

O

UTPUT

TERMINAL

POWER

BOARD

115VAC

RECEPTACLE

P

O

W

E

R

S

W

I

T

C

H

I

N

P

U

T

B

O

A

R

D

FAN

MOTOR

A

UX.

TRANS.

AUX.

TRANS.

RECTIFIER

AUX.

RECONNECT

PRIMARY

CURRENT

SENSOR

WIRE FEEDER

RECEPTACLE

RS232

CONN.

THERMOSTATS

STATUS

LIGHT

THERMAL

LIGHT

CURRENT FEEDBACK

VOLTAGE FEEDBACK

65VDC

40VDC

CONTROL SIGNALS

P

WM

CAPACITOR

VOLTAGE

FEEDBACK

PWM

DRIVE

VOLTAGE

SENSE

RECEPTACLE

#1

#2

S

W

I

T

C

H

DRIVE

FEEDBACK

VOLTAGE

CAPACITOR

INPUT

CONTACTOR

INPUT

RECTIFIER

R

E

C

O

N

N

E

C

T

CONTROL BOARD

R

IGHT

SWITCH

BOARD

L

EFT

SWITCH

BOARD

M

AIN

TRANSFORMER

CURRENT

S

ENSOR

CHOKE

OUTPUT

TERMINAL

O

UTPUT

TERMINAL

POWER

BOARD

115VAC

RECEPTACLE

P

O

W

E

R

S

W

I

T

C

H

I

N

P

U

T

B

O

A

R

D

FAN

MOTOR

A

UX.

TRANS.

AUX.

TRANS.

RECTIFIER

AUX.

RECONNECT

PRIMARY

CURRENT

SENSOR

WIRE FEEDER

RECEPTACLE

RS232

CONN.

THERMOSTATS

STATUS

LIGHT

THERMAL

LIGHT

CURRENT FEEDBACK

VOLTAGE FEEDBACK

65VDC

40VDC

CONTROL SIGNALS

P

WM

CAPACITOR

VOLTAGE

FEEDBACK

PWM

DRIVE

VOLTAGE

SENSE

RECEPTACLE

#1

#2

S

W

I

T

C

H

DRIVE

FEEDBACK

VOLTAGE

CAPACITOR

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC