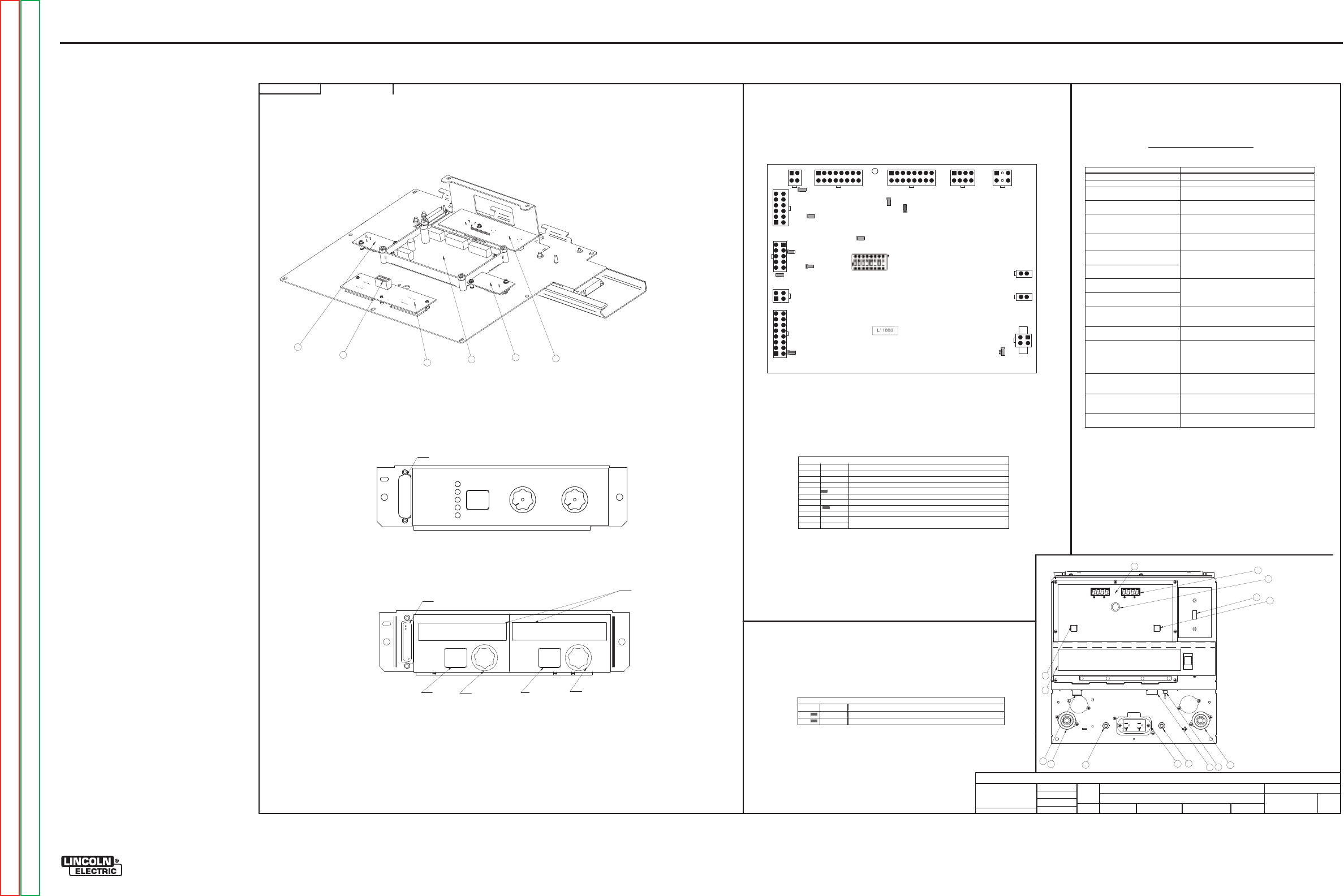

ELECTRICAL DIAGRAMS

G-5

INVERTEC® V450-PRO

SCHEMATIC - COMPLETE MACHINE - (G4875 SHEET 3)

G4875

INVE

RTE

C V450-P

RO

MAC

HI

N

E SC

HEM

ATIC

NONE

G4421

DO NO

T

SC

AL

E

T

HIS DR

A

WING

EQ

UIP

M

ENT

TYPE:

SUBJECT:

SCA

L

E:

UF

CRM36847

3

PAGE ___ OF

___

3

E

NGI

N

EE

RI

NG

CO

NT

RO

LLE

D

MA

NU

FA

CT

URE

R:

No

THIS DOCUMENT CONTAINS PROPRIETAR

Y

INFORMATION OWNED B

Y

LINCOLN GLOBA

L, INC.

AND MA

Y

NOT BE DUPLICATED, COMMUNICATED

TO O

THER PARTIES OR US

ED FOR

AN

Y

PURPOS

E WITHOU

T

THE EXPRES

S WRIT

TEN PERMISSION

OF LINCOLN GLOBAL, INC.

PR

OP

R

IETA

R

Y &

CON

FI

DE

NTIAL:

t

MAT

ERI

A

L TO

L

ER

ANC

E ("

"

) TO A

GR

EE

WITH

PU

B

LI

SH

ED

ST

ANDARD

S.

ON A

LL

AN

GL

E

S I

S ± .5 OF

A D

E

GR

EE

ON

3

PLACE

D

E

CIM

ALS

IS

± .

00

2 i

n.

(

±

0.

0

5

mm)

ON 2

PL

AC

E D

ECIM

AL

S I

S ± .02 in. (

±

0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

M

ANUF

ACTURING TO

L

ER

ANC

E

P

ER

E

2056

C

B2 AN

D F

U

SE, REVISED AMPS

R

EVISED

NOTE

N.B.

CHAN

GE

D

ET

AIL:

REFER

ENCE:

MA

T

ERI

AL

DIS

PO

SI

T

ION:

AP

PRO

VA

L

DA

T

E:

PROJ

EC

T

NUMBER:

DOCUMEN

T

NUMBER:

DOCUMEN

T

REV

ISI

ON:

IF PR

IN

T

ED

@ A

1

SIZ

E

UNI

T

S:

IN

CH

7-

13

-2

00

7

Dsn

ell

J.O'C

onn

or

.

DRAWN BY:

ENGINEER:

CL

EV

EL

AND

APPROVED:

CONTROL:

C

G4875

1.

Power Switch

2.

24V

-

42V

10 Amp Wire Feeder

Circuit Breaker

3.

115V

Auxiliary Power

&

Wire Feeder

Circuit Breaker

4.

6 pin Remote

5.

Work Stud

6.

Electrode Stud

7.

14 Pin

Wire feeder Remote

8.

Auxiliary Output (110V or 220V)

9.

STD Display Board

10.

Weld Terminal

/Remote ON

11.

Output

Control

/Remote Local

12.

Wire Feeder Polarity Switch

13.

Control Knob

14.

Mode Panel or (optional) Advance

Process Panel

f

ound underneath

Front Panel D

oor.

15. Thermal Light

Error codes for the

Invertec V450

-

PRO

The following is a list of possible error codes that the Power Wave can output via the status light

Error Code #

Indication

21 Unprogrammed Weld Mode.

Contact the Service Department for instructions on

reloading the Welding Software.

22 Empty Weld Table.

Contact the Service Department for instructions on

reloading the Welding Software.

23 Weld Table checksum error.

Contact the Service Department for instructions on

reloading the Welding Softwa

re.

31 Primary overcurrent error.

Excessive Primary current present. May be related to a

switch board or output rectifier failure.

32 Capacitor “A” under voltage

(Left side facing machine)

33

Capacitor “B” under voltage

(Right side facing machine)

Low voltage on the main capacitors. May be caused by

imp

roper input configuration, or an open/short circuit

in the primary side of the machine.

34

Capacitor “A” over voltage

(Left side facing machine)

35

Capacitor “B” over voltage

(Right side facing machine)

Excess voltage on the main capacitors. May be caused

by

improper input configuration, or an open/short

circuit in the primary side of the machine.

36 Thermal error

Indicates over temperature. Usuallyaccompanied by

Thermal LED. Check fan operation.

Be sure process

does not exceed duty cycle limit of the machine.

37 Softstart error

Capacitor precharge failed. Usually accompanied by

codes 32

-

35.

41 Secondary overcurrent error

The secondary (weld) current limit has been exceeded.

When this occ

urs the machine output will phase back

to 100 amps, typically resulting in acondition refered

to as “noodle welding”

43 Capacitor delta error

The maximum voltage difference between the main

capacitors has been exceeded. May be accompanied by

errors

32

-

35.

49 Single phase error

Indicates machine is running on single phase input

power. Usually caused by the loss of the middle leg

(L2).

Other

Use Snap Shot to interpret other errors

or Diagnostic

Sofware

CONTROL BOARD

Description of LED

functions on the Invertec V450

-

PRO

For reference only

G3632 Digital Power Supply Board

LED #

COLOR

FUNCTION

1

Red

Indicates +5VDC SPI supply is present

2

Red

Indicates +5VDC co

ntrol supply is present

2

1

Inve

rt

ec V450

-

PR

O

LE

D

9

LE

D

10

LE

D

5

LE

D

1

LE

D

2

LE

D

3

LE

D

4

LED6

LED7

LE

D

8

S1

J11

J10A

J10B

POWER BOARD S

J5

J6

J7

J8

J9

J4

J3

J2

J1

1

1.

STD DISPLAY PC BOARD ASSEMBLY

2.

SPI ASSEMBLY

3.

REMOTE

PC

BOARD ASSEMBLY

4.

LED SELECT PC BOARD ASSEMBLY

5.

FACTORY MODE PANEL ASSEMBLY

5

2

3

3

4

6

5

7

Case front Detail

Description of LED fu

nctions on the Invertec V450

-

PRO

For reference only

L11088 Digital Control PC Board

LED #

COLOR

FUNCTION

1

Green

Indicates +15VDC from power supply board is present

2

Green

Indicates

–

15VDC from power supply board is present

3

Gre

en

Indicates +5VDC for +5SPI from power supply board is present

4

Green

Indicates +15VDC for +15SPI from power supply board is present

5

Green

Indicates +5VDC for +5V from power supply board is present

6

Green

Indicates +5VDC for +5VRS232 from power sup

ply board is present

7

Red

FAULT Signal (See software group for coding)

8

Green

Indicates +5VDC for +5CAN from power supply board is present

9

Green

10

Red

ArcLink Status Indicators (Main System

Master

ArcLink Connection) Solid

Green only when functional (Se

e software for error codes)

Fac

tory

Mod

e Panel

9

10

11

12

13

8

4

4

Control Panel

C-

C S

tick Sof

t

C-

C S

tick

cr

isp

Ti

g G

ta

w

C

V

W

ir

e

C

V

In

ners

hield

Hot

St ar t

ArcControl

Touc

h

Start

TI

G

Hi

-Freq

TI

G

So

ft

C

risp

WEL

D

MODE

Sele

ct

-1

0

+10

0

1

10

5

M

em

or

y

Sele

ct

Adj

us

t

Sele

ct

Ad

vance

Pr

ocess Panel

(O

pt

iona

l)

14

(S

1isn

ot

use

d)

8 Memo

ry

Select

weld process

(enco

der)

Select

Hot

Start

or Arc

Weld

Adjust

Hot

Start

&

Arc control

(encod

er)

A

lpha Numeric

Display

R

S232

R

S232

15

G-5

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC