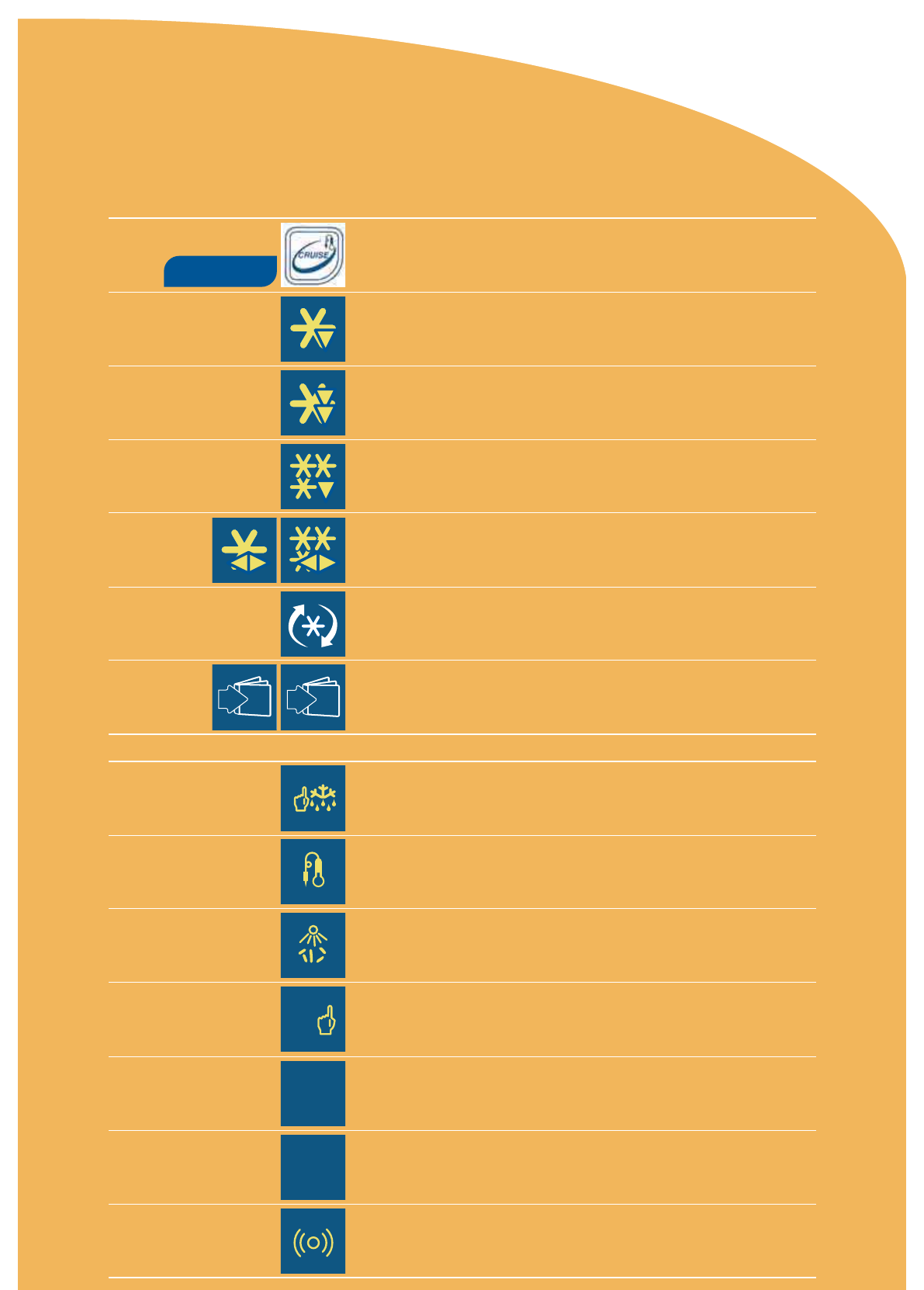

Chilling cycles

with probe the ARTE (Algorithm for Residual Time Estimation) activates automatically

Advanced functions

Patent

pending

Cruise Automatically adjusts the working temperature to the type of food. It reduces

the chilling time and prevents superficial burns.

Soft Chilling

air temperature: -2 °C

Ideal for delicate foods, such as leafy or cut vegetables, seafood, small portions

of meat, pastries, small cakes, biscuits, pasta.

Hard Chilling

air temperature: -20 °C

Ideal for solid or firm foods, such as vegetables (grown below the ground),

soups, stocks and sauces, stews and casseroles, whole joints of meat and

poultry.

Shock freezing

air temperature: -36 °C

Ideal for freezing all kinds of food – raw, half or fully cooked – that need to be

stored over a long period of time. (Version chiller-freezers)

Holding at:

+3 °C

or

-22 °C

Automatically activated at the end of each cycle, to save energy and maintain

the target temperature.

Can also be activated manually to turn air-o-chill

®

into a storage refrigerator or

freezer. (Version chiller-freezers)

Turbo cooling Alarms the user to set a working temperature between -36 and +3 °C.

Indicated for countinuous and bulk production.

P1

Customizable

Programs

(2 per cycle)

Can be replaced (via software) by the “ICE CREAM” Freeze and Hold

and the “ICE CREAM” turbo cooling cycles.

P2

Manual start

for the defrost function

Intelligent defrost cycle is activated automatically whenever necessary and as

long as necessary.

Can also be activated manually.

Core Probe selector It allows to alternately monitor the temperature of 3 different core probes

(optional) inserted in different kinds or sizes of food.

UV sterilizing Built–in UV lamps (only on request) to sterilize the cooling chamber after use.

NF

UK

Norms profile selection Through this function, it is possible to select the reference norms

(UK and NF are pre-programmed).

A third profile, can be created to match local or customer specific regulations.

SET

Settings Setting of the following parameters:

• date and time • customer profile limits • alarms and HACCP options •

bactericide cycle time (only with UV lamps)

HACCP

HACCP recall Calls up the HACCP events stored in the memory.

Operation Alarms recall Calls up the operational events registered by the auto-diagnostic system.

75electrolux user guide