4 – 1

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391SSG

Section 4 • Operation

Operation

All operation (setpoint adjustments, calibrations,

monitoring) of the compressor unit is done through

the Compact Logix PLC. For additional procedural

information, refer to Compact Logix PLC Software

Manual (35391CL).

Oil Inspection

WARNING

When working with LFG, NG or other dangerous

or fl ammable gases, ensure there are adequate

ventilation and vapor detectors. Refer to national fi re

and building codes. Failure to comply may result in

serious injury or death.

WARNING

Avoid skin contact with any condensate or oil. Wear

rubber gloves and a face shield when working with

condensate or oil. Failure to comply may result in

serious injury or death.

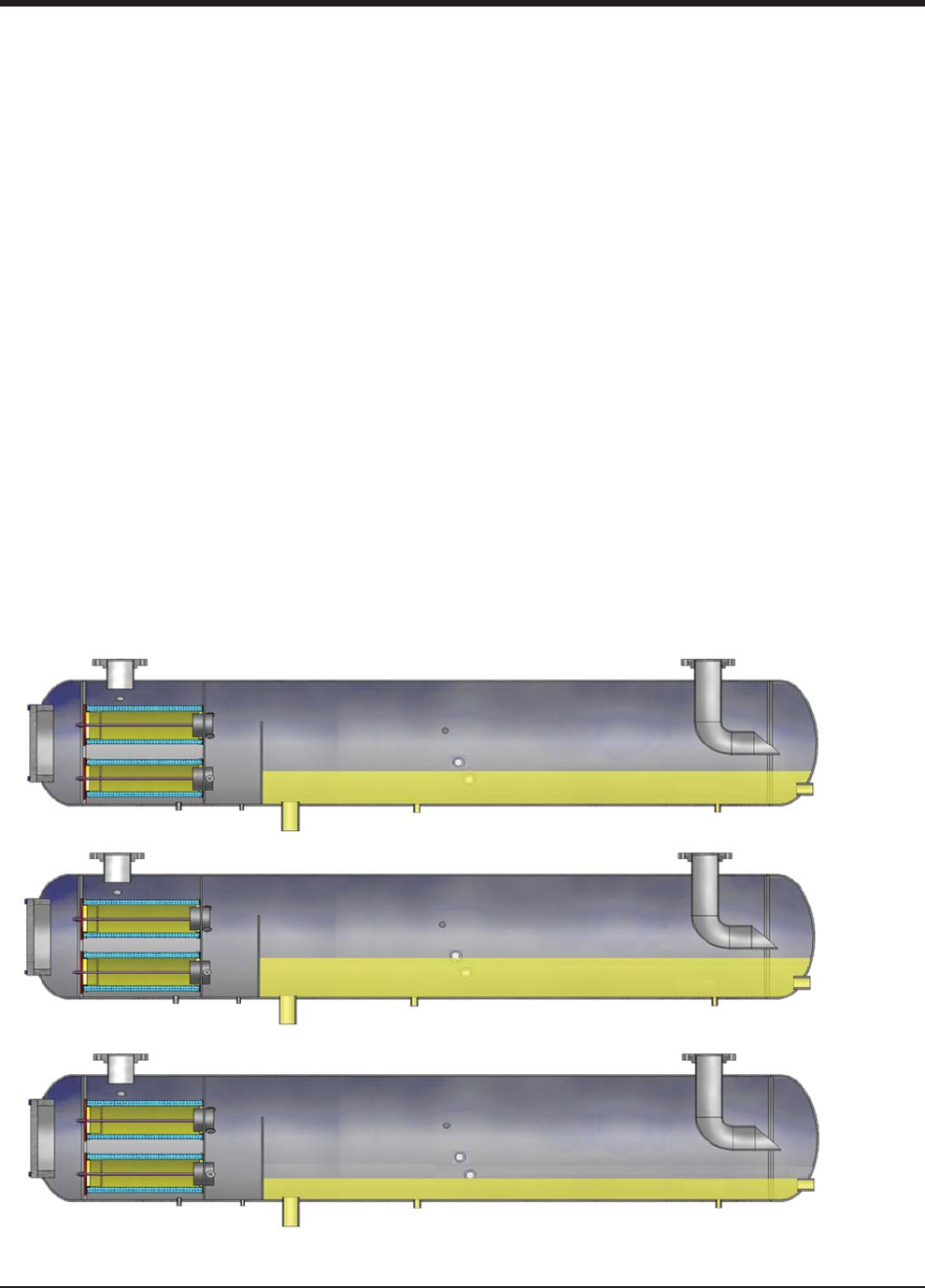

Inspect oil level through sight glasses on the oil

Figure 4-1. Oil Operating Levels

Normal Operating Level

Maximum NON-Operating Level

Minimum Operating Level

separator, see Figure 4-1. Oil Operating Levels. Drain or

fi

ll oil as required. For oil draining and fi lling procedure,

see Oil Charging and Oil Draining in Section 5.Oil Flow

with Dual Oil Filters

Dual Oil Filters

On compressor units equipped with dual oil fi lters, only

one fi lter should be in operation at a time.

NOTE

During operation, both oil fi lter outlet shut-off valves

should be open. This will help minimize the sudden loss

of oil pressure when switching between oil fi lters for

servicing.

Refer to Oil Filter Replacement in Section 5 for further

details.