5 – 5

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391SSG

Section 5 • Maintenance/Service

Oil Charging

WARNING

Avoid skin contact with oil. Wear rubber gloves and a

face shield when working with oil. Failure to comply

may result in serious injury or death.

CAUTION

Do not add oil to the coalescent side of the oil

separator. Failure to comply may result in damage to

equipment.

Normal oil level operating range must be maintained for

optimum performance and to prevent damage to equip-

ment. See Figure 4-1. for normal operating levels. There

are a couple of ways to maintain oil, while the compres-

sor unit is in operation and during shutdown.

Tool Required:

• Oil Pump, Maximum 2-3 GPM with Motor approved

for Division 1 or Division 2 and with ability to over-

come suction pressure.

Charging During Operation:

During operation, if the oil level is low, add oil to the

operating compressor through the suction oil charging

valve, see Figure 5-3. Pump oil into the compressor until

the oil level reaches the normal operating level. Watch

this level carefully to maintain proper operation. Never

allow the oil to reach a level higher than the Maximum

Operating Level, since this may impair the operation and

effi ciency.

1. Using a properly selected oil pump, connect oil

pump to suction oil charging valve, see Figure 5-3.

2. Open suction oil charging valve and fi ll oil separator

to Normal Operating Level.

3. Once the Normal Operating Level has been reached,

shut off the oil pump and close the valve. Disconnect

and remove oil pump.

Charging During Shutdown:

During shutdown, if oil is to be added, charging can be

performed through the drain valve located underneath

the oil separator, see Figure 5-3. During shutdown, oil

can be added to the Maximum Non-Operating Level.

For shutdown procedure, see Compressor Unit Isolation

procedure.

1. Using a properly selected oil pump, connect oil

pump to oil separator drain valve.

2. Open oil separator drain valve and fi ll oil separator to

Maximum NON-Operating Level.

3. Once Maximum NON-Operating Level has been

reached, shut off oil pump, close oil separator drain

valve and remove oil pump.

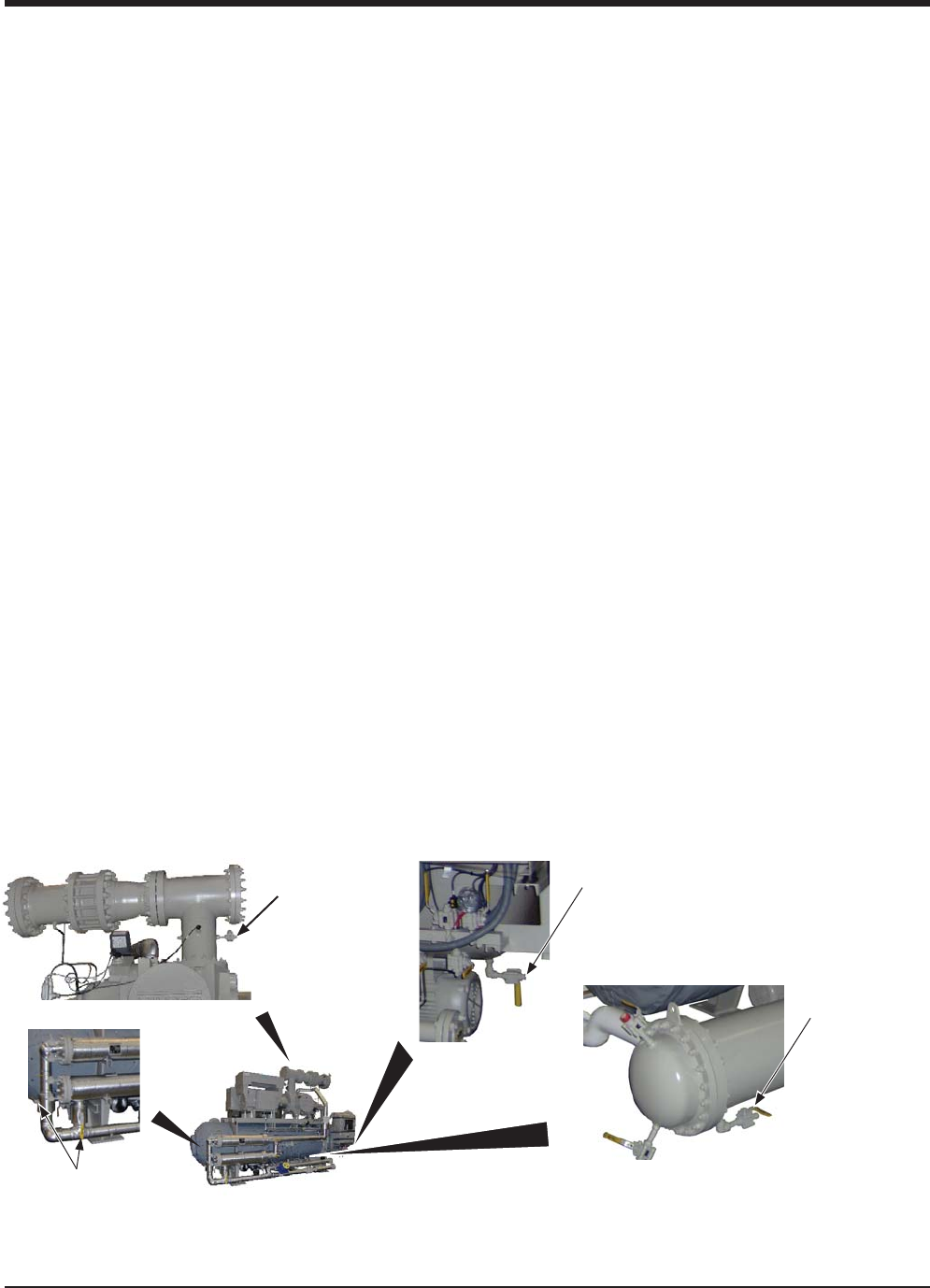

Figure 5-3. Suction Oil Charging Valve, Oil Cooler Drain Valve and Oil Filter Shut-Off Valves

Suction Oil

Charging Valve

View Rotate 180°

Oil Drain Valve

(Oil Separator)

Oil Drain Valve

(Oil Cooler)

View From Back - View Rotate 180°

Oil Filter

Shut-Off Valves