5 – 11

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391SSG

Section 5 • Maintenance/Service

16. If locking tab is being used, bend locking tabs in

gap towards shaft and around bolt.

17. Install set screw in hub cap to secure key in keyway

of shaft.

18. Tighten set screw, see Table 5-4.

Drive Center Member Installation and

Alignment

NOTE

Always adjust motor to the compressor. The

compressor is aligned to the frame.

19. Adjust motor position as needed to obtain a dis-

tance of 5” between both hub faces.

20. Soft Foot. The motor must sit fl at on its base (+/-

0.002”). Any soft foot must be corrected prior to

center member installation.

NOTE

If the driver or driven equipment alignment

specifi cation is tighter than these recommendations,

the specifi cation should be used. Also, be sure

to compensate for thermal movement in the

equipment. The coupling is capable of approximately

four time the above shaft alignment tolerances.

However, close alignment at installation will provide

longer service with smoother operation.

The fl ex disc pack is designed to an optimal thickness

and is not to be used for axial adjustments.

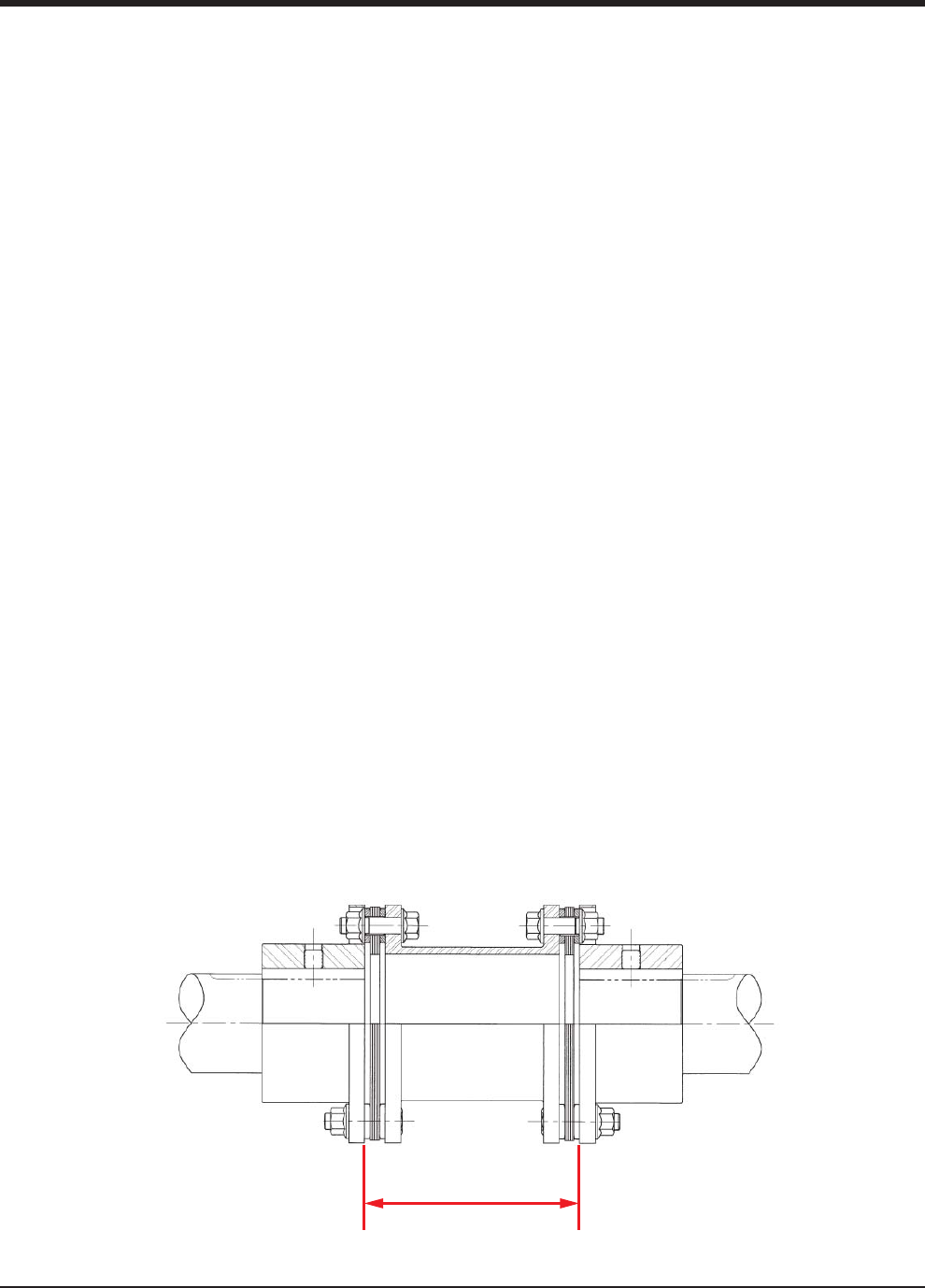

21. Axial Spacing. The axial spacing of the shafts should

be positioned so that the fl ex disc packs are fl at

when the equipment is running under normal op-

erating conditions. This means there is a minimal

amount of waviness in the fl ex disc pack when

viewed from the side. This will result in a fl ex disc

pack that is centered and parallel to its mating

fl ange faces. Move the motor to obtain the correct

axial spacing, see Table 5-3 and Figure 5-8.

22. Angular Alignment. Rigidly mount a dial indicator on

one hub or shaft, reading the face of the other hub

fl ange. Rotate both shafts together, making sure

the shaft axial spacing remains constant. Adjust the

motor by shimming and/or moving so that the indi-

cator reading is within 0.002” per inch of coupling

fl ange, see Figure 5-9.

23. Parallel Offset. Rigidly mount a dial indicator on one

hub or shaft, reading the other hub fl ange outside

diameter. Indicator set-up sag must be compen-

sated for. Rotate both shafts together. Adjust the

equipment by shimming and/or moving so that the

indicator reading is within 0.002” per inch of the

axial length between fl ex disc packs, see Figure 5-9.

With the coupling in good alignment the bolts will fi t

through the holes in the fl anges and the disc packs more

easily.

NOTE

All bolt threads should be lubricated. A clean motor

oil is recommended. On size 226 and larger, a link

must be put on bolt fi rst. Remove the disc pack

alignment bolt. Proceed to mount the second disc

pack to the other hub in the same way.

Ensure that the beveled part of the washer is against

Hub Distance

Figure 5-8. Hub Distance (Axial Spacing)