5 – 29

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391SSG

Command Shaft Assembly

Replacement

REMOVAL

NOTE

The following steps can be used to remove or install

either the capacity or volume command shaft

assemblies.

1. Shut down and isolate compressor unit, see

Compressor Unit Shutdown and Isolation

procedure.

2. Remove actuator, see Actuator Assembly

Replacement procedure.

3. Remove four socket head cap screws (457) and

Nord-Lock washers (477) securing mounting plate

(415) to manifold.

4. The command shaft and mounting plate may now

be removed from the compressor.

INSTALLATION

5. Install the command shaft assembly with a new

O-ring (446) on the manifold. Make sure that the

command shaft tongue is engaged in the cross

shaft slot. Rotate the bearing housing so the vent

holes point down, this will prevent water and dust

from entering the vents.

6. Install the actuator mounting plate with the four

socket head cap screws and Nord-Lock washers se-

curing it with proper torque.

7. Perform leak check, see Compressor Unit Leak

Check procedure.

Command Shaft Seal Replacement

REMOVAL

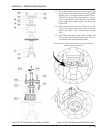

1. Remove bolts (281) holding the shaft seal cover

(218). Insert two of the bolts into the threaded

jacking holes to assist in removing the cover. There

will be a small amount of oil drainage as the cover

is removed.

2. Remove the rotating portion of the shaft seal

(219C).

3. Remove oil seal (230) from cover.

4. Remove the stationary portion of the shaft seal

(219B) from the seal cover using a brass drift and

hammer to tap it out from the back side of the seal

cover.

5. Seal with stationary carbon face (219B) and rotat-

ing mirror face (219C).

Figure 5-29. Command Shaft Seal

INSTALLATION

CAUTION

Care must be taken when handling the shaft seal and

mirror face so it is not damaged. Do not touch the

carbon or mirror face as body oil and sweat will cause

the mirror face to corrode.

NOTE

When replacing the stationary members of the seal

on the VSSG 291 thru VSSG 601 the roll pin in the

cover is used only with the seal assembly having a

stationary mirror face. If a seal assembly with a

stationary carbon face is installed, the roll pin must

be removed.

6. To install the carbon cartridge part of the seal in the

seal cover; clean the seal cover, remove protective

plastic from the carbon cartridge, do not wipe or

touch the carbon face. Lubricate the sealing O-ring

with clean compressor lubricating oil. If applicable,

align the hole on the back of the carbon cartridge

with the dowel pin in the seal cover. Install car-

tridge using seal installation tool or similar (see tool

lists).

7. Wipe clean, the compressor input shaft and the

Section 5 • Maintenance/Service