OPERATION

PRO-CUT 60

B-7

Cutting Expanded Metal

1. Cut expanded metal with OUTPUT

CURRENT CONTROL set near the mid-

range position using the same methods

listed under Cutting Thin Gauge Metal.

Keep the following points in mind:

a. Place a thin piece of scrap metal over

the area to be cut and then cut

through both to make cutting easier.

b. After 30 seconds of cutting expanded

metal, the pilot arc changes from a

bright continuous arc to an arc that

rapidly goes on and off. This

produces a slight spatter. You can

still cut metal when this condition

occurs as long as metal has been cut

in the last five seconds. If metal is not

cut in this condition for more than five

seconds, the arc shuts off and the

machine goes into postflow.

c. The pilot arc duty cycle is 20 seconds

out 80 seconds. If the torch trigger is

continuously pulled and released to

obtain a bright, continuous arc, the

duty cycle limit will be reached and

the arc will be turned off for the duty

cycle limit. When the arc is turned off,

the OUTPUT ON and FAULT LEDs

flash alternately.

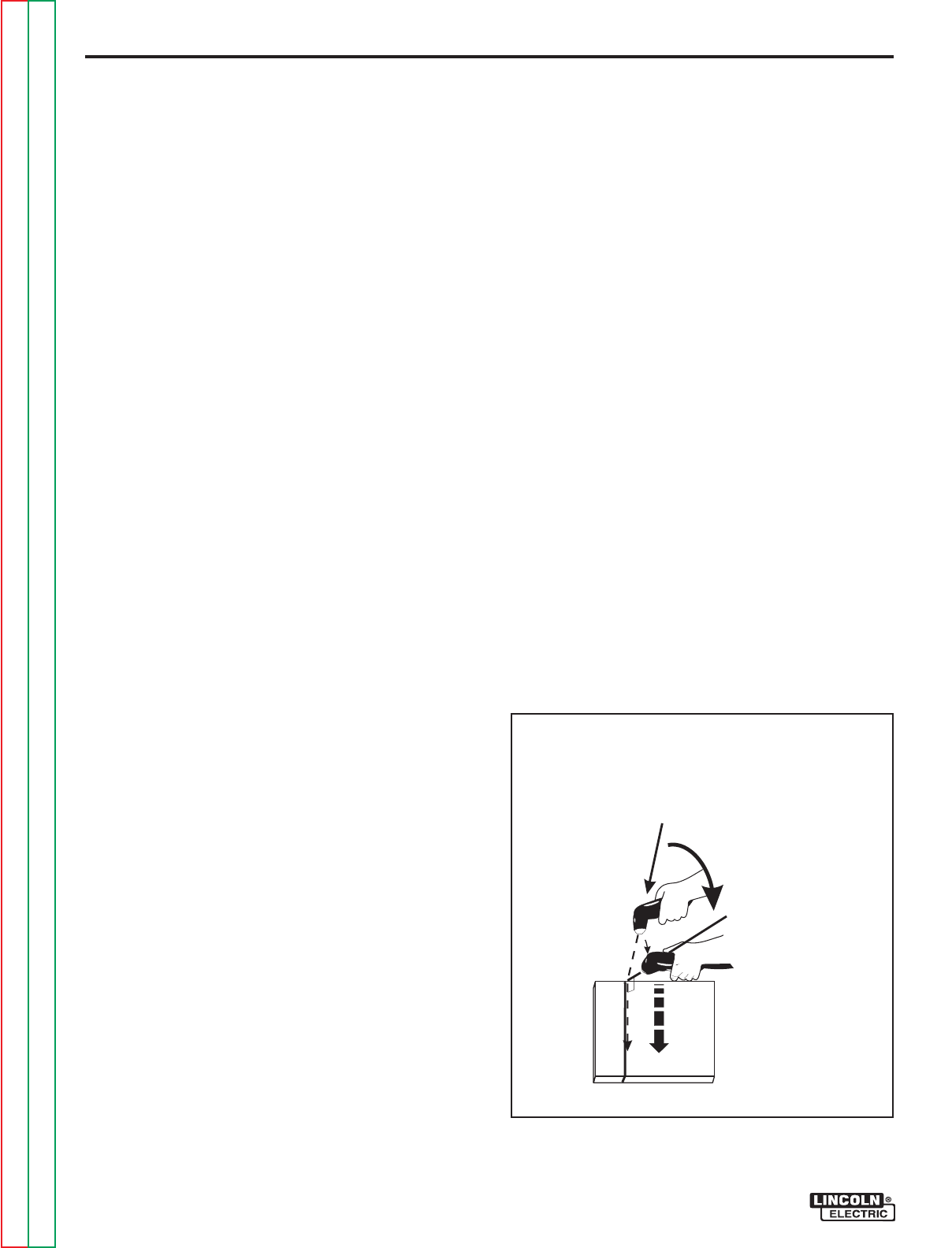

Cutting Thick Sections of Metal

1. Set the OUTPUT CURRENT CONTROL

above the mid-range (Red) position.

a. Use the minimum current needed to make

a satisfactory cut.

2. Hold the torch nozzle about 1/8" (3.2mm) from

the cutting surface. Do not let the torch nozzle

touch the work or carry a long arc.

a. Use the S24114 Drag Cup to protect the

torch.

b. Use only the .052" (1.3mm) or the .042"

(1.0mm) nozzles. Do not use the .035"

(0.8mm) nozzle for cutting thick sections of

metal.

3. Start the cut from the edge of the work piece

when possible. Pierce the work piece by slow-

ly lowering the torch onto the metal at a 30

0

angle. This will blow the dross away from the

torch tip. Slowly rotate the torch to vertical

position as the arc becomes deeper. See

Figure B. 2.

4. Keep moving while cutting. Cut at a steady

speed without pausing.

FIGURE B.2 -- Cutting Thick Piece of Metal.

3030

00

VERVERTICAL ANGLETICAL ANGLE

FOR CUTTINGFOR CUTTING

CUT

90

0

TORCH AT 30

0

ANGLE

TO PIERCE

ROTATE TO

90

0

ANGLE TO CUT

3/993/99

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC