Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

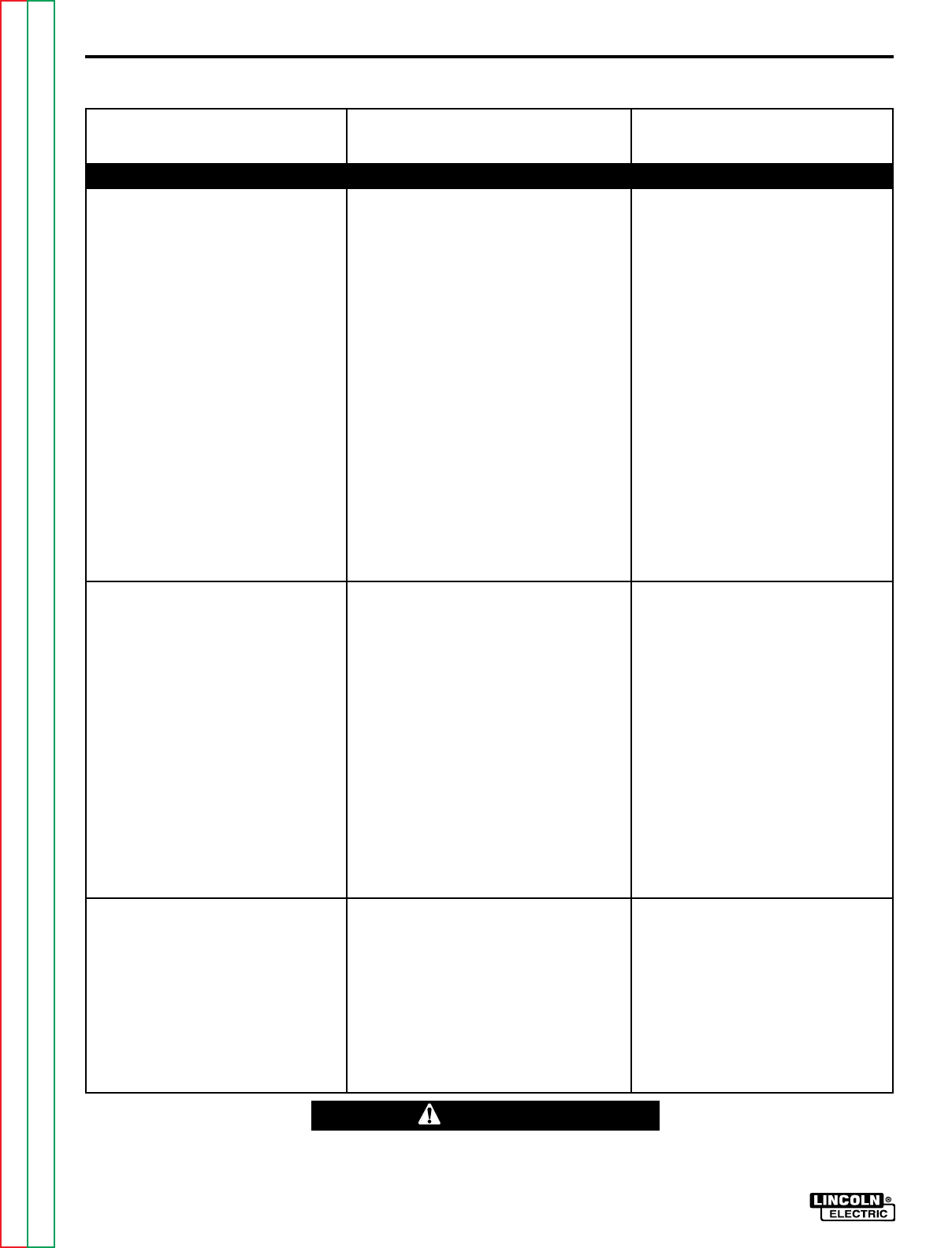

TROUBLESHOOTING & REPAIR

PRO-CUT 60

F-11

PROBLEMS

(SYMPTOMS)

The arc starts but sputters

badly. (If cutting expanded

metal, condition may be nor-

mal, see operation section.)

The "MALFUNCTION" or

"FAULT" LED starts blinking

during cutting or gouging.

Pilot arc is OK but cutting arc

will not establish.

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. Make sure the torch con-

sumables are tight and are in

good condition. Replace if

necessary.

2. Check the air supply for oil or

water contamination. If

there is oil or water present

the air supply must be fil-

tered or the machine

switched to nitrogen or

bottled air.

3. Make sure air pressure is

60 to 65 PSI.

4. Check spark gap setting -

.060” - clean if necessary.

1. This is an overcurrent con-

dition caused by a surge of

current the machine is not

designed to handle.

Release the torch trigger

and resume cutting or

gouging.

2. Check torch consumables

for wear - replace if neces-

sary.

1. Make sure work cable and

clamp are secure.

2. Clean any painted or heavily

corroded work surfaces.

RECOMMENDED

COURSE OF ACTION

1. The torch and cable

assembly could be faulty.

Perform the Torch, Torch

Cable Assembly, and

Internal Trigger and Safety

Circuit Tests.

2. Check Pilot Resistor R2.

See Wiring Diagram

3. The Control Board could be

faulty. Replace.

4. Check “Jump Start Diode” -

see wiring diagram.

1. Perform the Torch,

Torch Cable Assembly,

and Internal Trigger and

Safety Circuit Tests.

2. Perform the Transistor

Module Test.

3. Perform the Main Trans-

former Test.

4. The Control Board could be

faulty. Replace.

1. Perform Transistor Module

Test.

2. Perform Power Board Test.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln

Electric Service Department for technical troubleshooting assistance before you proceed call 216-383-2531 or 1-800-833-9353.

TROUBLESHOOTING GUIDE

Observe Safety Guidelines

detailed in the beginning of this manual.

CUTTING PROBLEMS

CAUTION