Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

B-4 B-4

RANGER 300 D AND 300 DLX

ADDITIONAL FEATURES

RANGER 300 D (K1522-1)

• One constant voltage wire-feed welding range - 80

to 200 amps.

The wire feed setting permits the Ranger 300D to be

used with the LN-25 Wire Feeder and .035, .045 or

.068 NR®-211-MP Innershield electrodes. Limited

MIG (GMAW) welding can also be done with .030 or

.035 L-50 and L-56 using blended Argon shielding

gas. “Auto-Idle” functions when using an LN-25

with an internal contactor.

ADDITIONAL FEATURES

RANGER 300 DLX (K1522-2)

• Four constant voltage (CV) wire-feed welding

ranges with fine control on each range for welding

at 40 to 300 amps.

• Excellent arc characteristics with MIG (GMAW) and

recommended Innershield electrodes (FCAW).

• Wire feeder amphenol receptacle (14-pin) for quick

connection of control cable.

• Voltmeter for reading CV wire-feed welding arc volt-

age.

• Built in contactor with front panel selection of

“cold” or “hot” welding terminals.

• Aluminum TIG welding when used with K930-1 TIG

Module. Output contactor control with Amptrol.

• Recommended wire feeders are the LN-25 with 42

Volt Remote Output Control Module or with internal

contactor and all models of the LN-7.

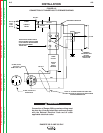

RECOMMENDED APPLICATIONS

WELDER

The RANGER 300 provides excellent constant current

AC/DC welding output for stick (SMAW) welding and

for TIG welding, and it offers constant voltage output

for DC semiautomatic wire feed welding.

GENERATOR

The RANGER 300 gives AC generator output for medi-

um use demands.

LIMITATIONS

• The Ranger 300 is not recommended for any

processes besides those that are normally per-

formed using stick welding (SMAW), TIG welding

(GTAW), MIG (GMAW) welding and Innershield®

(FCAW) welding.

• The RANGER 300 D/DLX is not recommended for

pipe thawing.

• During welding, generator power is limited and out-

put voltages can drop. Therefore, DO NOT OPER-

ATE ANY SENSITIVE ELECTRICAL EQUIPMENT

WHILE YOU ARE WELDING. See Table B.5 for

permissible simultaneous welding and auxiliary

power loads.