Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

B-13 B-13

RANGER 300 D AND 300 DLX

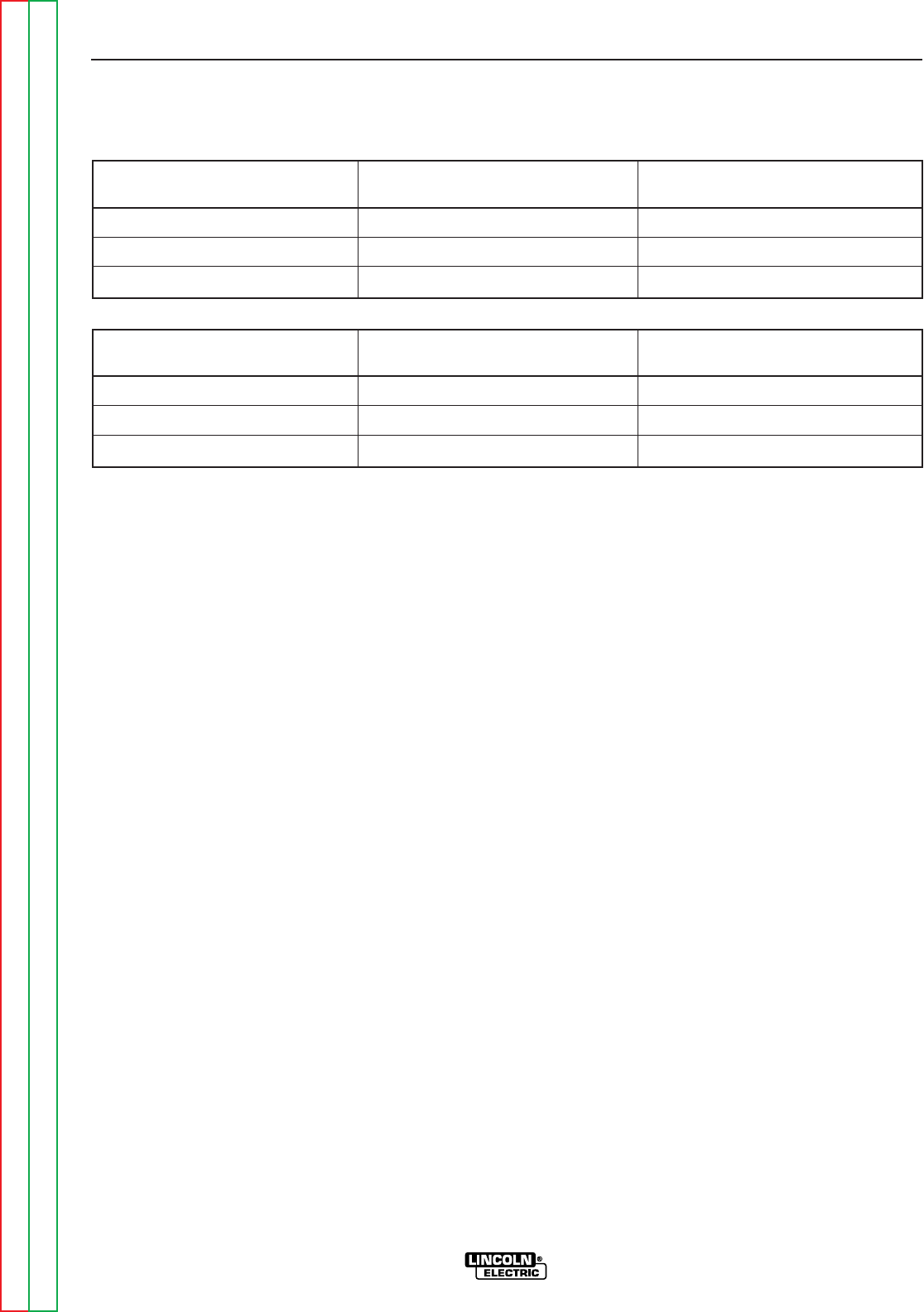

TABLE B.2

AC TIG WELDING – TIG ELECTRODE/RANGE SETTINGS

Pure (EWP) “Range” Appropriate

Tungsten Diameter Switch Settings Welding Current

1/8” 75, 100 or 140

(1)

100 - 200 amps

3/32” 50, 75 or 100 50 - 100 amps

1/16” 50, 75 or 100 45 - 150 amps

1% Thoriated “Range” Appropriate

Tungsten Diameter Switch Settings Welding Current

1/8” 100, 140 or 180 160 - 250 amps

3/32” 50, 100 or 140 100 - 180 amps

1/16” 50 or 100 60 - 120 amps

(1)

The welding current will be approximately 200 amps with the range switch set at 120 and the OUTPUT CON-

TROL set at 10. Do not use a range setting higher than 120 for AC TIG welding.

DC WIRE FEED WELDING (CV) WITH

RANGER 300 DLX

1. Connect one of the following: the LN-25, LN-7 or

LN-8 Wire Feeder.

2. Some recommended Innershield electrodes are:

.068 NR-211MP, .068 NR-232, NR-203 series, 5/64

NR-311, and 5/64 NS-3M. Lincore® 33 and 55

hardfacing electrodes can also be used. Cable

length and other conditions can affect the ultimate

results of this application. Request Lincoln publi-

cation N-675 for additional information.

Recommended Outershield electrodes are .045

(1.1 mm), .052 (1.3 mm), and 1/16 (1.6 mm)

Outershield 71 and 1/16 (1.6 mm) Outershield 70.

Request Lincoln publication GS-200 for additional

information.

For MIG welding, the recommended electrodes are

.030 (0.8 mm), .035 (0.9 mm) and .045 (1.1 mm) L-

50 and L-56. You must use a blended shielding

gas such as C25 (75% Argon, 25% CO

2

). Request

Lincoln publication GS-100 for additional informa-

tion.

3. Set the IDLER CONTROL to “AUTO” for the LN-25

or “HIGH” for the LN-7 or LN-8 and start the diesel

engine.

4. Set the RANGE switch to either HIGH, MEDIUM

HIGH, MEDIUM LOW, or LOW (CV-red) depending

on your wire size and speed.

5. Set the POLARITY SWITCH to either WIRE WELD-

ING DC+ or WIRE WELDING DC- depending on

the electrode.

6. Set the OUTPUT control to a setting between 1 and

10 that gives the most stable arc for the applica-

tion. Try a higher RANGE switch setting if the arc

is unstable.

7. Strike an arc and begin welding. The OUTPUT

control can be adjusted while welding. DO NOT

change the RANGE switch setting while welding.

This can result in damage to the switch.

AFTER YOU FINISH WELDING:

1. Stop the engine.

2. Allow the work to cool completely.

3. Remove the work clamp from the work.