Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INSTALLATION

F-40 F-40

RANGER 300 D AND 300 DLX

CHARGING CIRCUIT TEST (continued)

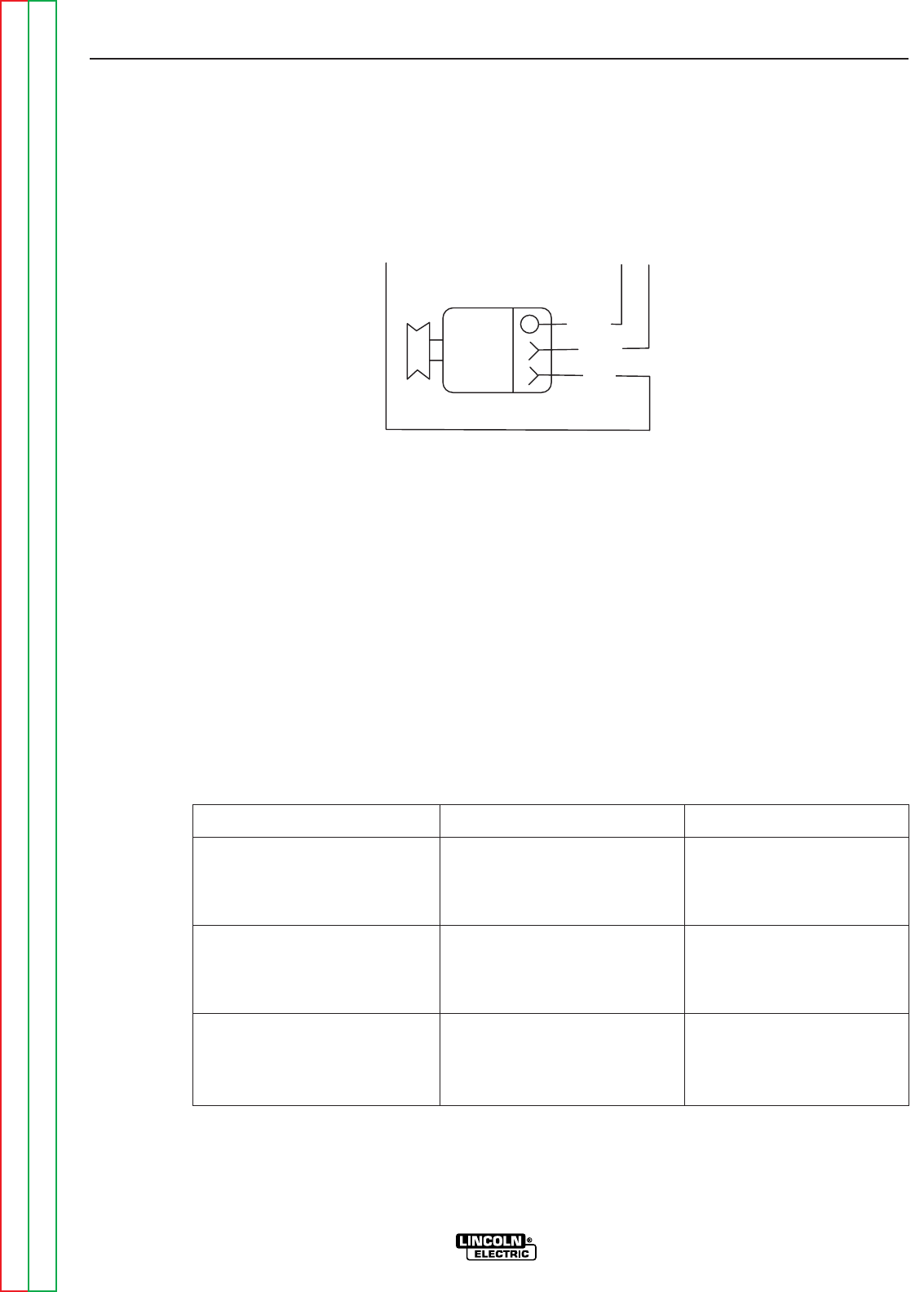

FIGURE F.13 – VOLTAGE REGULATOR LEADS

TEST PROCEDURE

1. With the 5/16” and 3/8” nut drivers, remove

the right case side.

2. Locate the engine alternator and leads. See

Figure F.13.

3. Set the voltmeter for DC volts and check for

the typical DC voltages according to the

Charging Circuit Test Chart below.

4. If the DC voltages are correct, the engine

alternator is operating normally.

If any of the voltage readings are missing or

not normal, the engine alternator or associ-

ated wiring may be faulty. See the Wiring

Diagram.

CHARGING CIRCUIT TEST CHART

TEST CONDITIONS TEST POINTS TYPICAL VOLTAGE

Ignition Switch Off Lead 222D to Frame Ground 12 VDC

Ignition Switch Off Lead 224A to Frame Ground 0 VDC

Ignition Switch Off Lead 227 to Frame Ground 0 VDC

Ignition Switch On Lead 222D to Frame Ground 12 VDC

Ignition Switch On Lead 224A to Frame Ground 12 VDC

Ignition Switch On Lead 227 to Frame Ground 0.7 VDC

Engine running at 3700 RPM Lead 222D to Frame Ground 14.5 VDC

Engine running at 3700 RPM Lead 224A to Frame Ground 14.3 VDC

Engine running at 3700 RPM Lead 227 to Frame Ground 14.3 VDC

B

IG

L

222D

224A

ALTERNATOR

227