Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-11 F-11

RANGER 300 D AND 300 DLX

TROUBLESHOOTING GUIDE OBSERVE SAFETY GUIDELINES

DETAILED IN THE BEGINNING OF THIS MANUAL.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-800-833-9353.

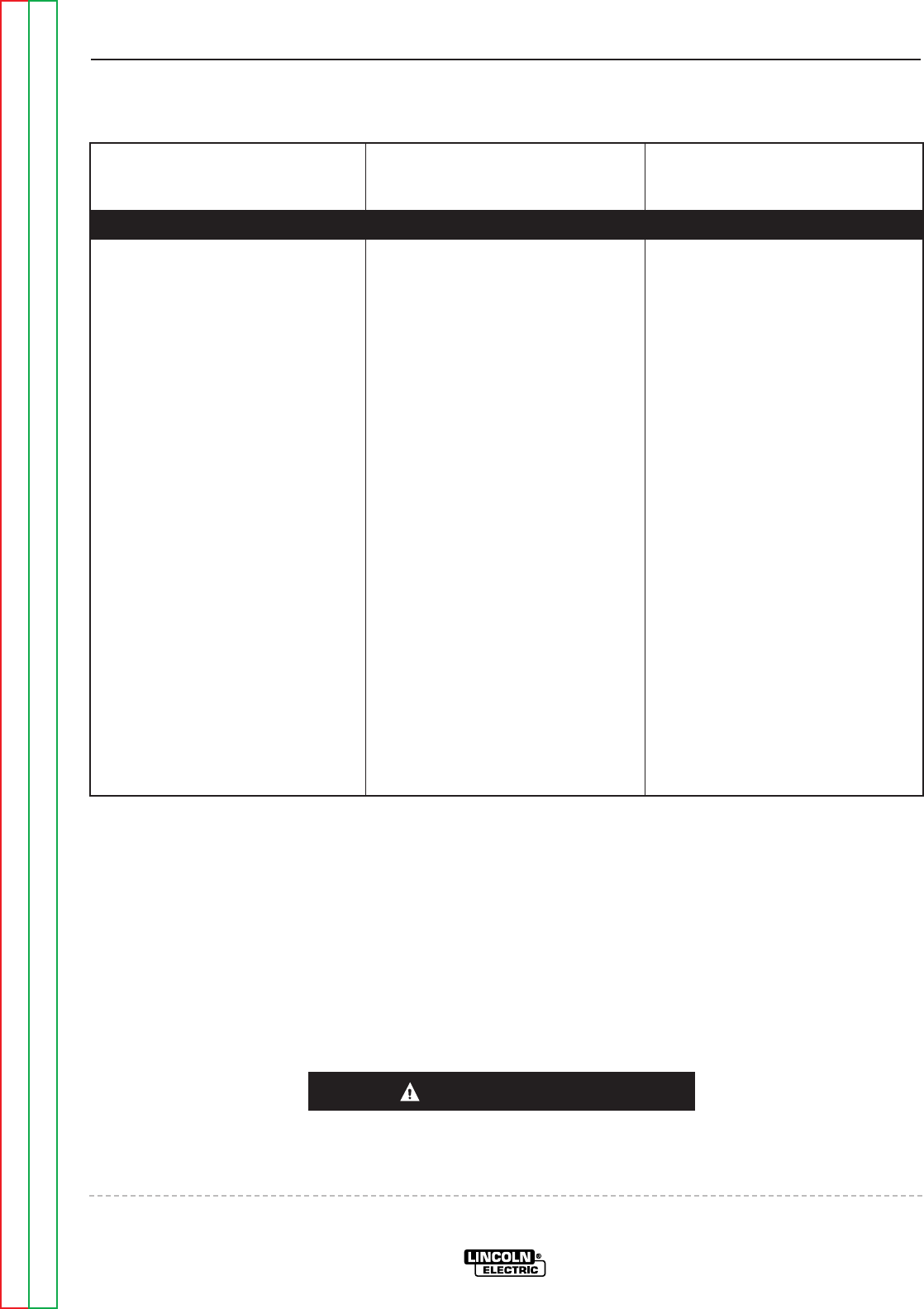

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

Engine will not idle down to low

speed. Machine has normal weld

output and auxiliary power.

1. Make sure the idler switch (S5)

is in the “Auto” position.

2. Make sure there is NOT an

external load on the weld termi-

nals nor the auxiliary power

receptacles.

1. With the idler switch (S5) in the

“Auto” position, no external

load connected to the machine

and the engine running, check

the DC voltage at leads #222J

to #214 located at the idler

solenoid. Also check from

leads #222H to #213. No (zero)

volts is normal. If 12VDC IS

present, the control board may

be faulty. If no voltage is indi-

cated and the solenoid is keep-

ing the engine in a high speed

condition, the idler solenoid

may be faulty. Also check for a

mechanical restriction in the

throttle linkage.