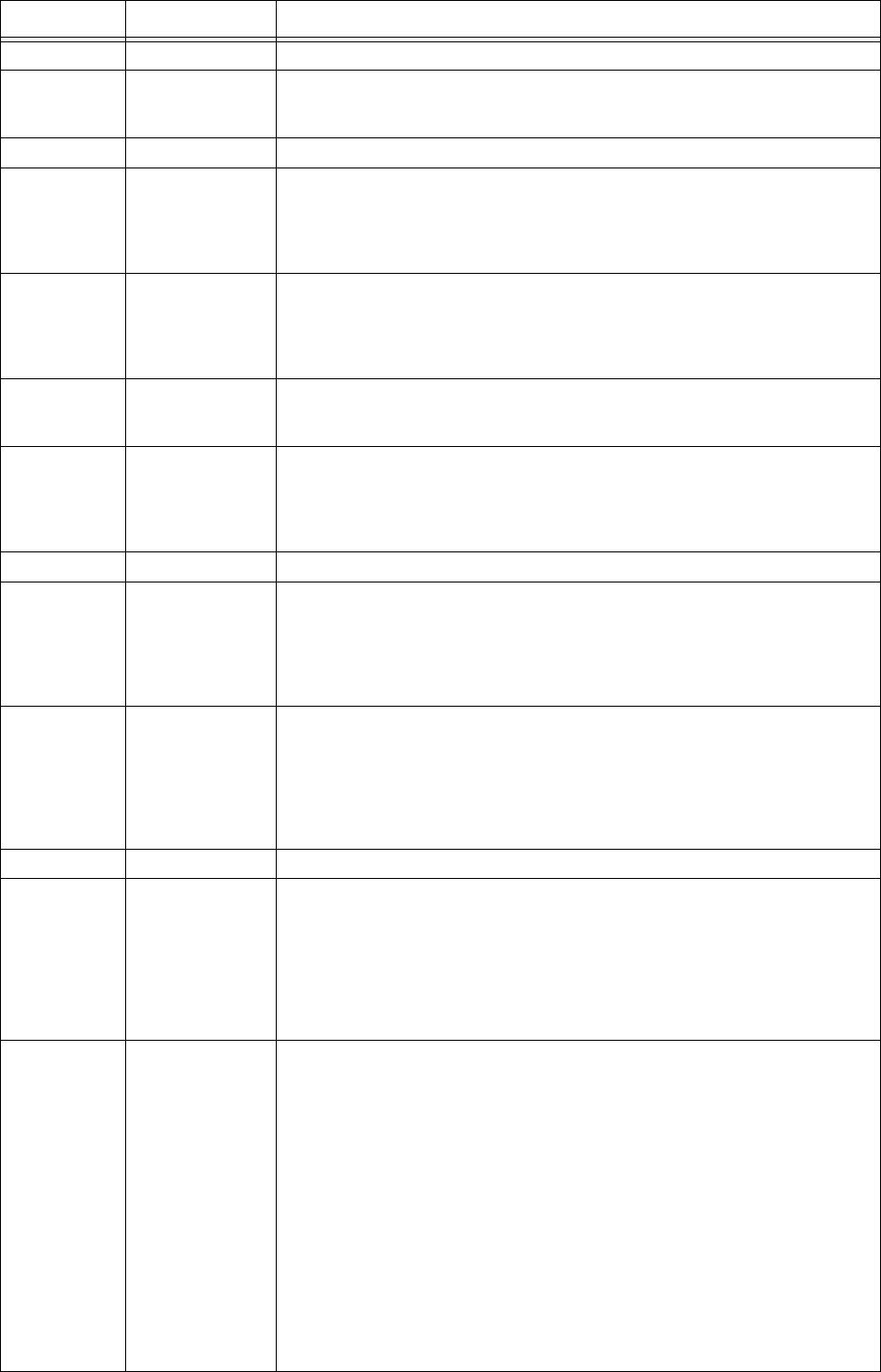

■Revision history

Date of print Specifications No. Details of revisions

2012-03-13 BFP-A8878

・First print.

2012-03-21 BFP-A8878-A

・ The painting color was corrected. (Error in writing)

・ Notes were added to the example of safety measures. (The measure against the noise, The

electric specification of the output terminal)

2012-04-04 BFP-A8878-B

・ CE marking specification was added.

2012-05-17 BFP-A8878-C

・ The position repeatability was corrected (improvement).

・ ON voltage/ON current and OFF voltage/ OFF current of the parallel input-and-output

interface were corrected (error in writing).

・ The mechanical stopper position to change the operating range to +/-130 degree was

corrected to N12 (Error in writing)

2012-06-05 BFP-A8878-D

・ Limitation of the electric current value of the relays (coil) connected to the external

emergency stop input was added.

・ The connection method of the Fig.3-27 : AXMC terminal connector (CR750) corrected to

"soldering."

・ The description of the capability value of pose repeatability was deleted.

2012-09-03 BFP-A8878-E

・ The connector name of hand input signal/output signal of "Fig.2-24: Wiring and piping for

hand" was corrected.

・ The power supply capacity was corrected.

2012-10-04 BFP-A8878-F

・ The notes were added to "Fig 3-24: Example of EMC noise filter installation".

・ The lithium battery (ER6) was added to The United Nations’Recommendations on the

Transport of Dangerous Goods.

・ The notes about installation of the controller and the robot arm were added. (neither direct

rays nor the heat of lighting)

2012-10-11 BFP-A8878-G

・ “Table 1-1: Combination of the robot arm and the controller” was corrected.

2012-11-20 BFP-A8878-H

・ The statement about trademark registration was added.

・ The notes about the input-output connected to the controller were added. (do not ground

the + side of 24V power supply prepared by customer)

・ ”Declaration of Incorporation” was updated.

・ The metal plate which fixes "Hand internal wiring and piping set (option)" was changed to

attachment of the robot arm in standard.

2013-01-11 BFP-A8878-J

・ EC-Statement of Compliance was updated.

・ Note of the external emergency stop were added (opens the connector terminal at factory

shipping).

・ The connectors of RH-3FH series machine cable (AMP1, AMP2, BRK) were combined as

CN1 connector.

・ Type names of machine cables (option, special specifications) were changed. (No-CE

specification)

2013-02-15 BFP-A8878-K

・ Type name of CR751 controller was corrected. (formerly: CR751-03HD-0)

2013-07-19 BFP-A8878-M

・ The simple spanner for resin nuts was added to the attachments of the external wiring/

piping box (option).

・ ”Declaration of Incorporation” and “EC-Statement of Compliance” were updated.

・ ”Fig.2-28: Wiring and piping system diagram for hand and example the solenoid valve

installation” was modified.

・The cautions of operating in a low temperature environment or after a prolonged stop in ”6.3

Precautions for handling” were modified.

・ The caution about fumigation of wood packing was added to ”6.3 Precautions for handling”.

2013-09-19 BFP-A8878-N

・ ”Fig.6-11: Limitations when connecting the relay etc. (CR750)” and ”Fig.6-12: Limitations

when connecting the relay etc. (CR751)” were corrected.

(Error output → Emergency stop output, Contactor controleoutput for additional axes →

Error output)

・ The descriptions of CR751-03HD1-0-S15 (CE marking specification controller) were added.

・ Type name of CR751 controller was corrected. (formerly: CR751-03HD)

・ The dimensions of screw hole position for fixing user wiring/p

iping were added.

・ The following descriptions of (5) in ”Fig.2-24 : Wiring and piping for hand” were corrected.

The power source wire only for the multifunctional hand → Spare wire

The connector pins name of robot side and connector name of counter side were added.

The connector pins name of counter side was corrected.

・ The descriptions of solenoid valve set were corrected, and explanations were added.

・ ”Fig.2-28 : Wiring and piping system diagram for hand and example the solenoid valve

installation” was corrected.

・ The useable length from the shaft end of Internal Wiring/Piping set for hand was corrected.

・ The descriptions about the ventilation duct which the robot of clean specification has were

corrected.