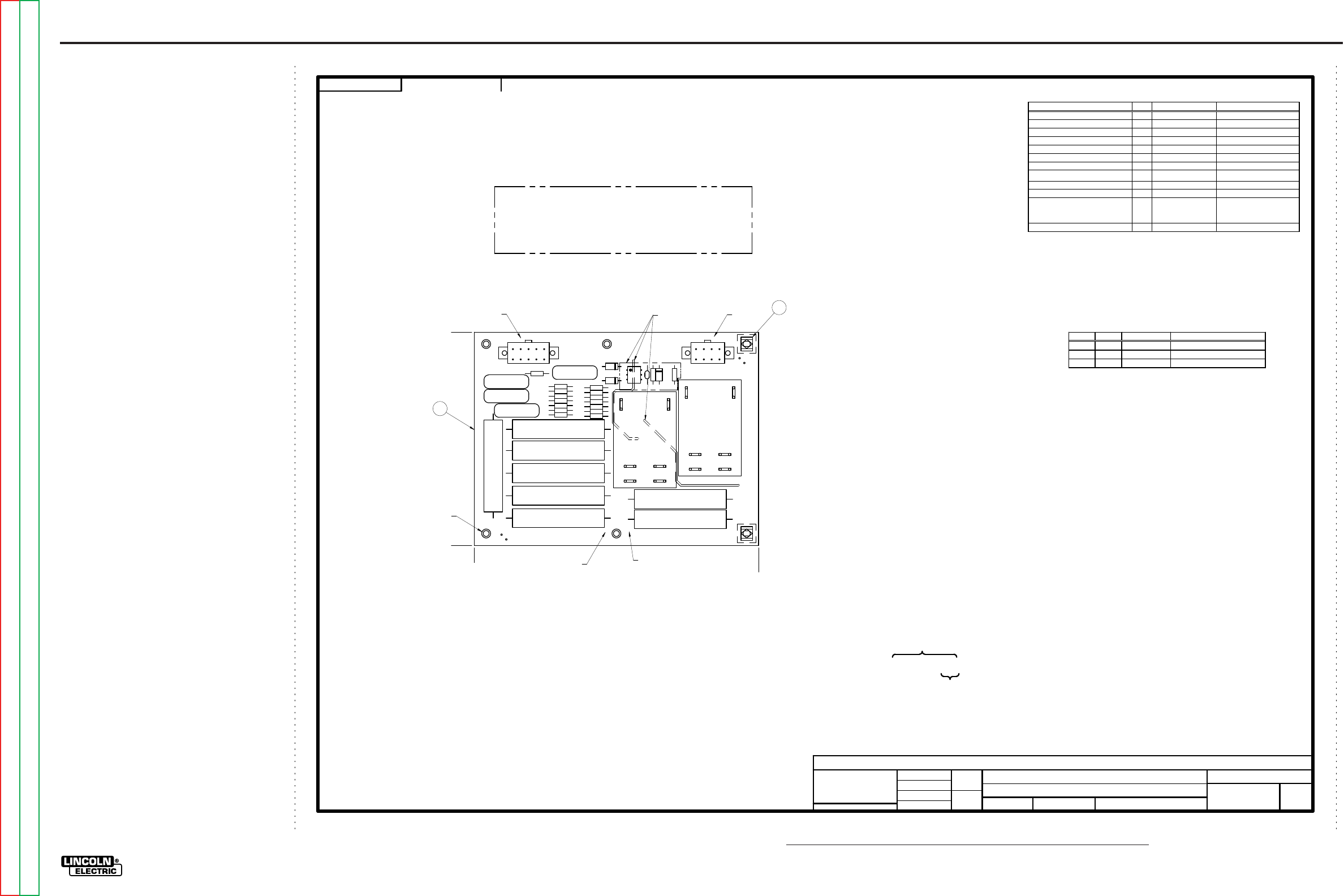

NOTE: Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. Individual Printed Circuit Board Components are not available from Lincoln Electric. This information is pro-

vided for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the

machine.

ELECTRICAL DIAGRAMS

G-22

PC BOARD ASSEMBLY - INPUT PC BOARD

L11396-2

INVERTER WELDERS

INPUT P.C. BOARD ASSEMBLY

1:

1

L11396

-1

FEI

-

U

NLESS

OTHERW

ISE

SPE

C

IF

IE

D

TOLERA

N

CE

MANUFACTURIN

G

TOLERANCE PER

E2056

ON 2 PLACE DECIMA

LS IS ± .02

ON 3

PLAC

E D

E

CI

MAL

S I

S ± .002

ON ALL ANGLE

S IS ±

.5 OF A DEG

REE

WITH PUBLISHED STANDARDS.

MA

TERIA

L TO

LERANCE ("

")

TO AGREE

t

DO N

OT S

CA

LE

TH

IS

D

RAW

ING

DRA

WN

B

Y:

DE

SI

GN INFORM

A

TION

E

NGIN

EE

R:

APPROVED:

REFERENCE:

EQU

IP

ME

NT

TYPE

:

SU

BJ

EC

T:

SCA

L

E:

L11396-2

MATERIAL

DISPOS

ITI

ON:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

C

RM3440

9

1

PA

GE

___

OF

___

1

ENGINE

ERING CONTROL

L

ED

MANUFACTURER:

No

DOCUME

NT

N

UMB

E

R:

DOCUMENT

REVISION:

T

HIS

DOC

UME

N

T C

ON

TAINS P

R

OP

RIETA

RY IN

FO

RMATIO

N

OW

NE

D BY L

IN

C

OLN

GLOBAL, IN

C. A

N

D MAY NOT BE

D

UPLI

CA

TE

D,

C

OMMU

NI

CA

TE

D

TO OT

HE

R PA

R

TIES O

R

USE

D

FO

R A

NY P

U

RP

OSE WIT

HOU

T THE E

X

PRESS

W

RITTE

N PE

RMISSIO

N

OF LIN

C

OLN

GLOBAL, IN

C.

PROPRI

ETA

RY & CONFIDE

NTIAL:

B

3/16/2

00

7

REVISE

D M

AKE SPE

CIFI

C

ATIO

N

CHANGE DET

AI

L:

S

O

L

I

D

E

D

G

E

ST

RP

CAPACITORS = MFD / VOLTS

RESISTORS = OHMS/WATTS

N.A. THIS AREA TO BE COVERED ON BOTH SIDES OF BOARD WITH ITEM 2 PRIOR TO

ENCAPSULATION. MATERIAL MUST BE APPLIED THRU SLOTS FROM BOTTOM

SIDE TO COMPLETELY FILL TO

UNDERSIDE OFDEVICE ON COMPONENT SIDE.

N.B. P.C. BOARD HOLES TO BE FREE OF ENCAPSULATION MATERIAL.

N.C.

DO NOT COAT WITH ENCAPSULATION MATERIAL.

N.D.

APPLY ITEM 2 AS SHOWN, ALL EXPOSED LEADS MUST BE COVERED. MATERIAL

MUST BE APPL

IED PRIOR TO ENCAPSULATION.

N.E.

APPLY ITEM 2 ON N

ON

-COMPONENT SIDE OF BOARD PRIOR TO

ENCAPSULATION.

ALL EXPOSED PINS MUST BE COVERED.

MAKE PER E1911-ROHS

ENCAPSULATE WITH E1844

TEST PER E3647-I

SCHEMATIC REFERENCE: M19528-2B0

L11396-2

B0

IDENT

IFI

CATION

C

ODE

MA

NU

FA

CTURE

D A

S:

A

LL

C

OMP

ON

E

NT

SA

ND

MATE

RI

ALS

U

SE

DIN

TH

IS

ASSEM

BL

YARE TO

B

E

R

oH

S

C

OMPLIA

NT

PE

R

E4253.

P.

C

.

BOARD

BLA

N

K

INFORM

ATI

ON

(MAKES 8

B

OA

RD

SPE

R

PANEL, SEE ELE

CTR

ON

IC

FILE

F

OR

A

DDI

TI

ON

AL

IN

F

OR

MATI

ON)

BUY COM

PLETE AS

L11396

-B

(

2 LAYER BOARD PER E3281)

ITEM REQ'D

PART NO.

IDENTIFICATION

1 1 SEE BLANK INFO.

P.C. BD. BLANK

21.0OZ.

E2861

SEALANT

3 2 S14020-7 PLASTIC EXPANSION NUT

REFERENCES

QTY

PART NO. DESCRIPTION

C1

1

S16668-5

.022/50

CR1, CR2 2

S14293-18

DPSTRELAY

D1, D3 2

T12199-1

1N4004

D2

1

T12705-58

DIODE,1.0A,1500V

N.C.

J60

1

S24020-8

HEADER,VERTICAL

N.C.

J61

1

S24020-10

HEADER,VERTICAL

OCI1

1

S15000-22

OPTO ISOLATOR

R1, R2, R3, R6, R7, R8, R9, R10 8

S24376-3

100/1OW

R4

1

S19400-2673

267K 1/4W

R5

1

S19400-4750

475 1/4W

R11, R12, R13, R14, R15, R16,

R17, R18, R19, R20, R21, R22,

R23, R24, R25

15

S19400-3011

3.01K 1/4W

TP1, TP2, TP3, TP4 4

T13640-23

MOV,250J,660V

XXXXXXX

XXXXXXXX

XXX

XXX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

T

P1

T

P2

T

P3

OCI1

T

P4

C1

R4

R5

R2

R3

R10

R9

R6

R7

R8

R22

R24

R25

R23

R13

R14

R15

R16

R17

R18

R19

R20

R21

R12

R11

R1

D1

D2

D3

J61 J60

CR1

CR2

L1139

6-2

INPUT

0

6.00

±

.04

0

4.50

±

.04

1

N.

B.

N.D.

N.D.

N.D.

N.D.

N.

A.

3

G-22

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC