THEORY OF OPERATION

E-5 E-5

POWER WAVE 655/R

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

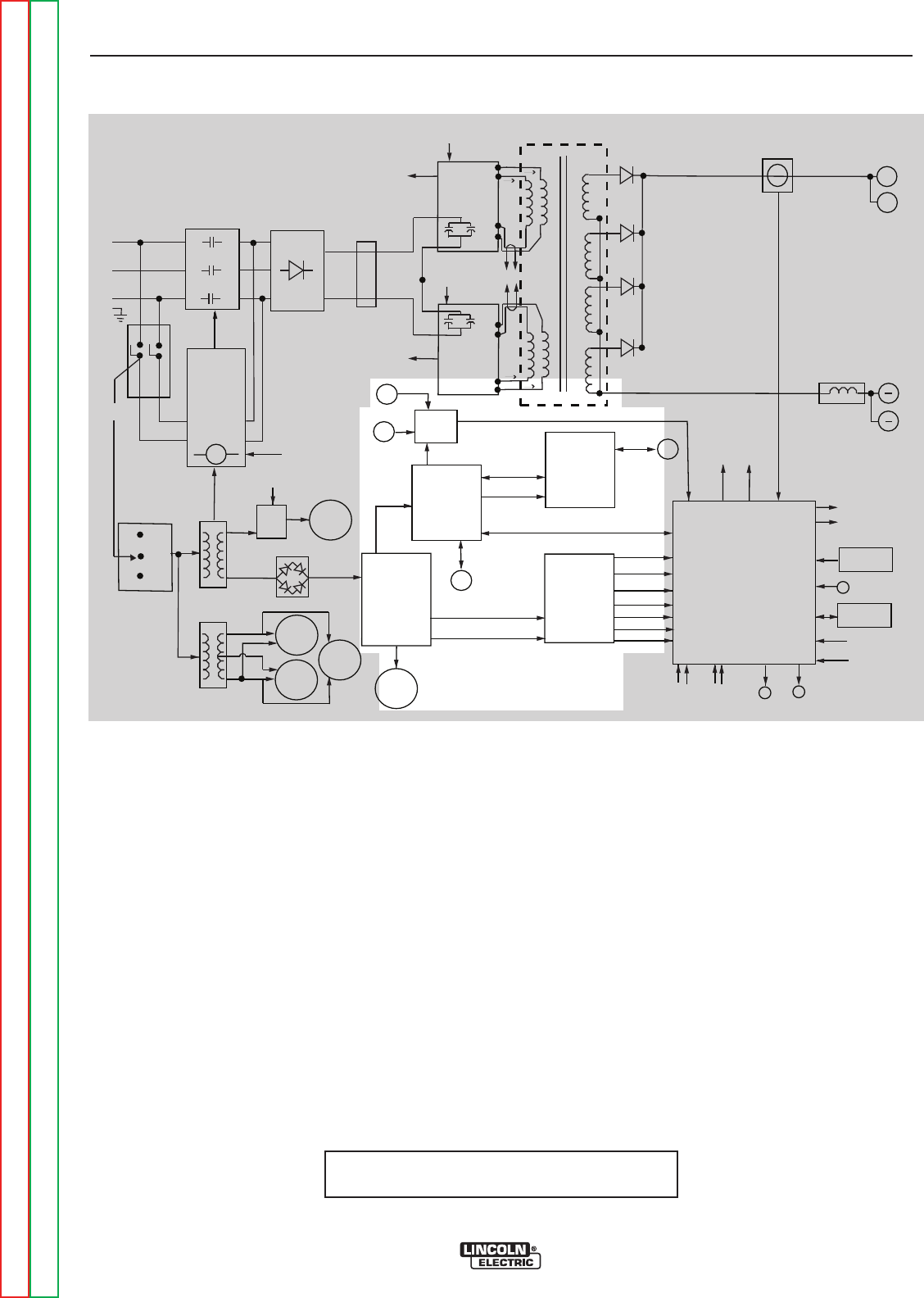

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

DC BUS BOARD, POWER BOARD,

FEED HEAD BOARD, GATEWAY

BOARD AND VOLTAGE SENSE

BOARD

The DC Bus Board receives approximately 65VDC

from the Bus Board rectifier. The DC Bus Board regu-

lates that 65VDC to a +40VDC supply. This regulated

40VDC is applied to the Feed Head Board, the

Ethernet/Gateway Board, the Power Board, and the

wire feeder receptacle.

The switching power supplies on the Power Board sup-

ply a variety of regulated DC voltages to the Control

Board. The Control Board uses these regulated volt-

ages to power the many circuits and communication

functions incorporated within the Control Board.

When the Feed Head Board activates the Voltage

Sense Board, the actual arc voltage is sensed (lead

67), and this information is delivered through the volt-

age sense board to the Control Board.

The Power Wave 655R uses two digital communication

platforms. Internally the PC boards communicate via

ArcLink. Externally the Power Wave 655R communi-

cates using the industry standard Ethernet or Device

Net protocol.The Ethernet/Gateway Board makes the

translation between the platforms possible. The Power

Wave 655R does not have a dedicated interface device

or board. The robot (or other input device – PLC, etc.)

acts as the user interface, issuing commands that are

translated by the Gateway Board to ArcLink compatible

messages. Figure E.5 depicts the flow of communica-

tion information.

FIGURE E-4 – DC BUS BOARD, POWER BOARD, FEED HEAD BOARD,

GATEWAY BOARD AND VOLTAGE SENSE BOARD

+

I

NPUT

BOARD

LEFT

SWITCH

BOARD

RIGHT

SWITCH

BOARD

INPUT

RECTIFIER

CR1

GATEWAY

BOARD

DC

BUS

BOARD

FEED

HEAD

BOARD

POWER

BOARD

CONTROL

BOARD

OUTPUT

CHOKE

ELECTRODE

TERMINAL

T

HERMOSTATS

T

1

T2

AUX

RECONNECT

RELAY

W

ATER

COOLER

115VAC

RECP.

115VAC

FAN

ARC LINK

WIRE

FEEDER

RECP.

S1

S6

C

ONNECTION

T

O WIRE

DRIVE

S1

S6

VOLT

SENSE

BOARD

MAIN

TRANSFORMER

S5

C

ONTACTOR AND PRECHARGE

C

ONTROL SIGNALS FROM

C

ONTROL BOARD

F

ROM CONTROL

B

OARD

2

4

V

A

C

1

15 VAC

5

2 VAC

2

30 VAC

4

0 VDC

4

0 VDC

40 VDC

40 VDC

ARC LINK

CONNECTION

TO

ROBOT

VOLTA GE SENSE

OUTPUT

C

AP.V/F

F

EEDBACK

CAP.V/F

FEEDBACK

IGBT DRIVE

FROM

CONTROL

BOARD

C

T CURRENT

T

O CONTROL

B

OARD

-15 V

+

15 V

+

5 V

+

5 V ARC LINK

+5V RS232

+15V SPI

STATUS THERMAL

LIGHT LIGHT

S

2 WORK

S

ENSE

L

EFT S.B.

CAP.V/F

RIGHT S.B.

CAP.V/F

S3

RS232

L

EFT CT

CURRENT

FB

C

U

R

R

E

N

T

F

B

A

RC LINK

IGBT

DRIVES

TO

LEFT

S.B.

TO

RIGHT

S.B.

6

7A

67B

SW1

BUS BOARD

RECTIFIER

CURRENT

TRANSDUCER

OUTPUT DIODES

D1 -D4

115 VAC

40 VDC

D

EVICE NET

V

OLTA GE SENSE SELECT

IGBT DRIVE

FROM

CONTROL

BOARD

+

5V SPI

RIGHT CT

CURRENT

FB

T

O FAN RELAY

CONTACTOR AND

PRECHARGE

CONTROL SIGNALS

6

5 VDC

WORK

TERMINAL

POWER WAVE 655/R

380-

415

440-

460

550-

575

+

ETHERNET/

A

A

HARMONIC

FILTER

C

POS

NEG

Auxiliary

Fan