Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

B-5 B-5

PRO-CUT 80

CONTROLS AND SETTINGS

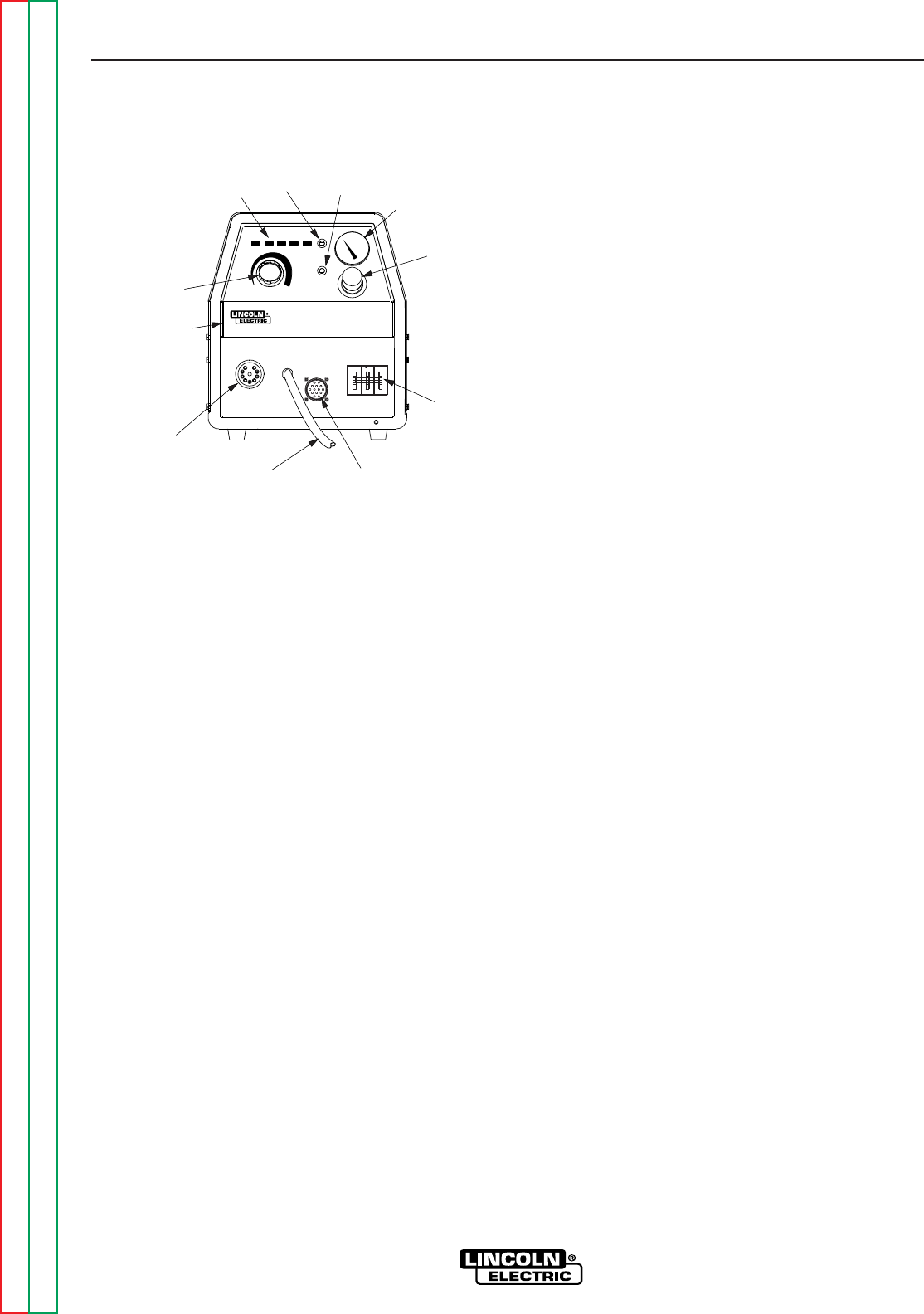

FIGURE B.2 - CASE FRONT CONTROLS

OUTPUT CURRENT CONTROL KNOB - Adjusts the

amount of cutting current applied. Affects cutting

speed, dross formation, cut width, heat zone and trav-

el speed.

TORCH CONNECTOR - Quick- connect type coupling

for the PCT 80 cutting torch.

WORK CABLE - Provides clamp and cable connection

to workpiece.

ON/OFF POWER SWITCH - Turns machine on or off.

GAS REGULATOR KNOB - Adjusts compressed gas

pressure delivered to the torch. Length of torch hose

is an adjustment factor. Optimum setting is 70-75 psi.

The gas purge button must be pressed in to set pres-

sure.

GAS REGULATOR GUAGE - Provides gas presssure

reading as set by the gas regulator knob.

GAS PURGE BUTTON - Used to check or set gas

pressure. Push in and hold to check pressure, then

continue to hold to set the pressure. Shuts off gas

when released.

RESET BUTTON - Used to reset the machine following

a safety circuit trip.

STATUS (DISPLAY) BOARD INDICATORS - Four lights

indicating Power, Gas Low, Thermal and Safety.

PILOT ARC CONSIDERATIONS

The Pro-Cut has a smooth, continuous pilot arc. The

pilot arc is only a means of transferring the arc to the

workpiece for cutting. Repeated pilot arc starts, in

rapid succession, is not recommended as these starts

will generally reduce consumable life.

Occasionally, the pilot arc may sputter or start inter-

mittently. This is aggravated when the consumables

are worn or the air pressure is too high. Always keep

in mind that the pilot arc is designed to transfer the arc

to the workpiece and not for numerous starts without

cutting.

When the pilot arc is started, a slight impulse will be

felt in the torch handle. This occurrence is normal and

is the mechanism which starts the plasma arc. This

impulse can also be used to help troubleshoot a "no

start" condition.

CUTTING OPERATION

When preparing to cut or gouge, position the machine

as close to the work as possible. Make sure you have

all materials needed to complete the job and have

taken all safety precautions. It is important to follow

these operating steps each time you use the machine.

• Turn the machine's ON/OFF POWER SWITCH to

the OFF position.

• Connect the air supply to the machine.

• Turn the main power and the machine power switch

on.

- The fan should start.

- The pre-charge circuit will operate for 3 seconds,

then the green "Power" status indicator should

turn on.

- If the "SAFETY" status indicator is lit, push the

"Reset" button. If there is no problem, the status

indicator will go off. If there is a problem, refer to

"STATUS INDICATOR" in this section.

• Be sure that the work lead is clamped to the work-

piece before cutting.

• Set the output current control knob for maximum

current for high cutting speed and less dross forma-

tion per Figure B.1. Reduce the current, if desired,

to reduce the kerf (cut) width, heat affected zone or

travel speed as required.

• Push-in and hold the Purge button to check or set

the gas pressure. Pull the pressure regulator cap out

and turn it to set the pressure.

- Adjust the gas regulator for 70 PSI for 25 foot

(7.62m) torches or 75 PSI for 50 foot (15.24m)

torches.

- Release the Purge button.

XXXXXXXX XXXXXXXX XXXXXXXX XXXXXXXX

PRO-CUT 80

Torch

Connector

Work

Cable

Input

Power

Switch

Output

Control

Knob

Consumable

Storage

(behind

door)

Status

Indicators

Reset

Button

Gas

Purge

Button

Gas

Regulator

Gauge

Gas

Regulator

Knob

Interface

Connector