Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-11 F-11

PRO-CUT 80

ELECTRIC SHOCK can kill.

• Have an electrician install and

service this equipment.

• Turn the input power off at the

fuse box before working on

equipment.

• Do not touch electrically hot parts.

• Prior to performing preventative mainte-

nance, perform the following capacitor dis-

charge procedure to avoid electric shock.

DISCHARGE PROCEDURE

1. Turn off input power and disconnect input

power lines.

2. Remove the 5/16" hex head screws from

the wraparound machine cover.

3. Be careful not to make contact with the

capacitor terminals located at the bottom of

the Input Power Board.

4. Obtain a high resistance and high wattage

resistor (25-1000 ohms and 25 watts mini-

mum). This resistor is not supplied with

machine. NEVER USE A SHORTING STRAP

FOR THIS PROCEDURE.

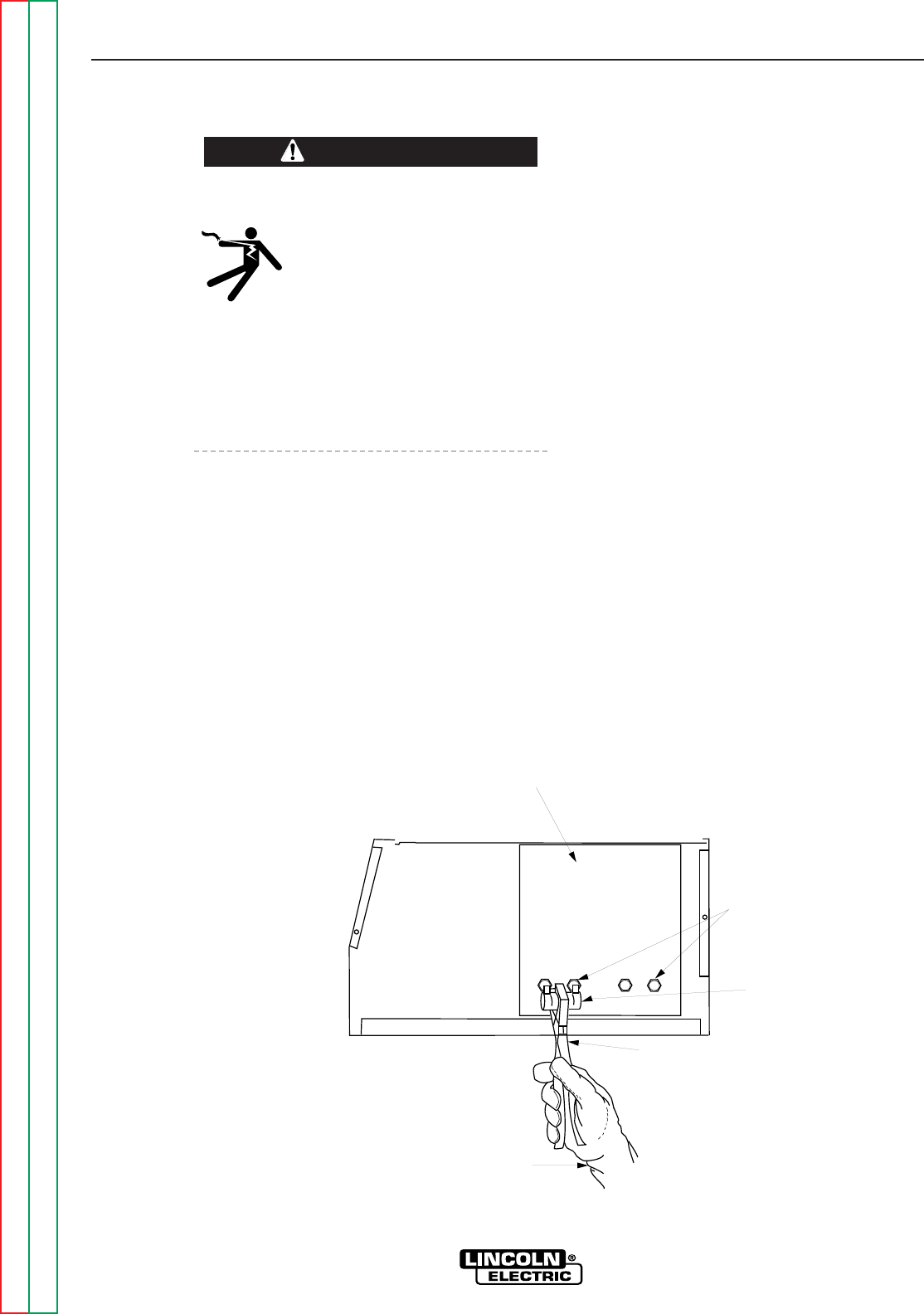

5. Locate the four capacitor terminals (large

hex head cap screws) shown in Figure F.1.

At the bottom of the PowerBoard

(203,206)(207,202)

6. Use electrically insulated gloves and insu-

lated pliers. Hold the body of the resistor

and connect the resistor leads across the

two capacitor terminals. Hold the resistor in

place for 10 seconds. DO NOT TOUCH

CAPACITOR TERMINALS WITH YOUR

BARE HANDS.

7. Repeat the discharge procedure for the

capacitor on the other two terminals.

8. Check the voltage across the terminals of

all capacitors with a DC voltmeter. Polarity

of the capacitor terminals is marked on the

PC board above the terminals. Voltage

should be zero. If any voltage remains,

repeat this capacitor discharge procedure.

WARNING

CAPACITOR

TERMINALS

POWER

RESISTOR

POWER

BOARD

RIGHT SIDE OF MACHINE

INSULATED

GLOVES

INSULATED

PLIERS

FIGURE F.1 – LOCATION OF INPUT FILTER CAPACITOR TERMINALS

INPUT FILTER CAPACITOR DISCHARGE PROCEDURE (continued)