TROUBLESHOOTING & REPAIR

F-33 F-33

PRO-CUT 80

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TRIGGER CIRCUIT TEST (continued)

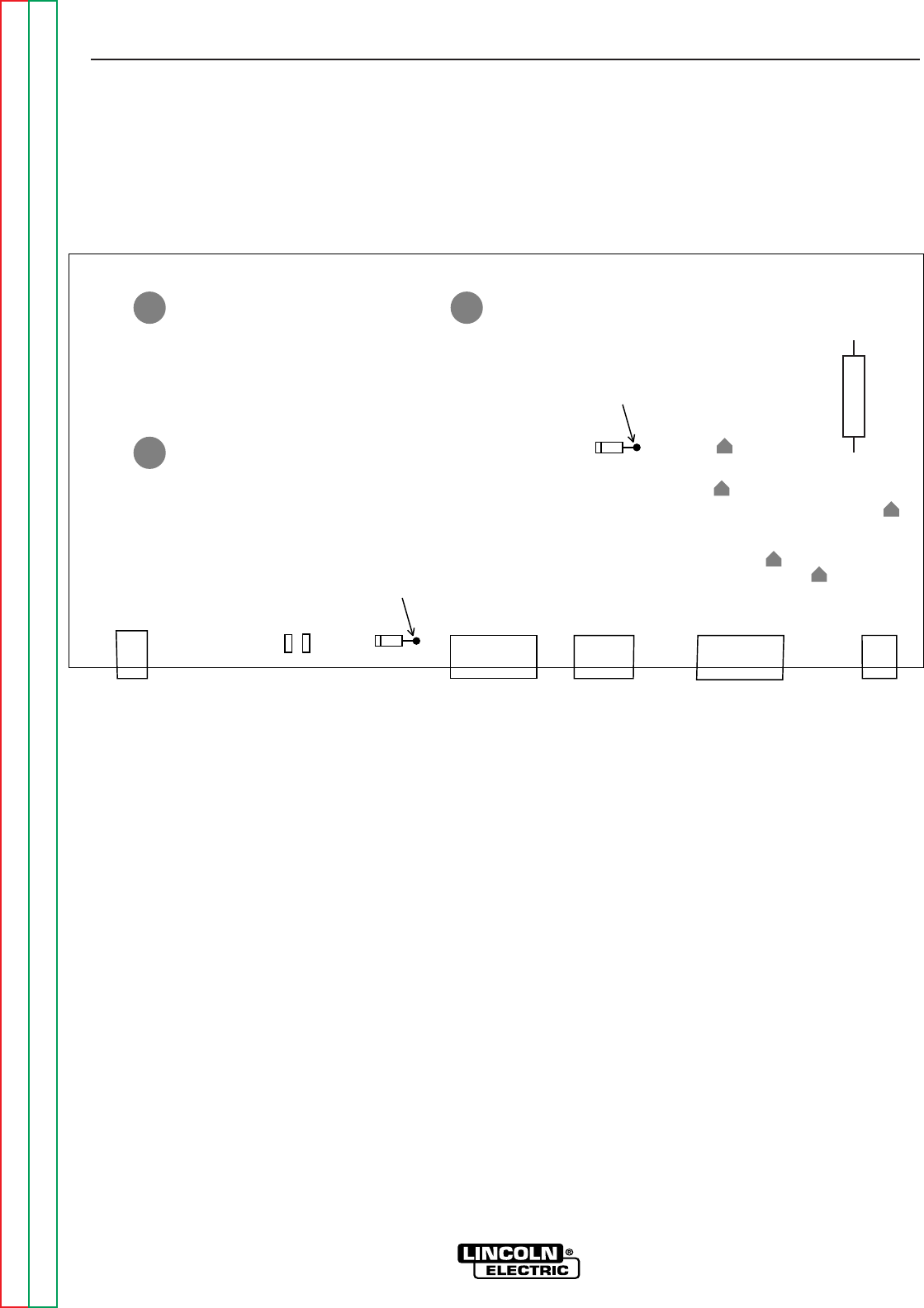

G3439 PRO-CUT 80 OUTPUT

LED1

LED2

D29

LED4

LED3

LED5

J33 J31 J34 J32 J30

X20

X40

X4 X2

(B12) (B11)

(B21)

TEST POINT

+

C13

D25

TEST POINT

FIGURE F.10 - OUTPUT BOARD TRIGGER CIRCUIT TEST POINTS AND LEDS

PRO-CUT 80 OUTPUT BOARD

LED DEFINITIONS

LED1: (Red) This light indicates that 24 VAC is

being supplied to the output board from the aux-

iliary transformer. It also shows that the 24 VAC

is being rectified to approximately 32 VDC. This

DC voltage is used for the "parts-in-place"

check for the torch circuit.

LED2: (Red) This light indicates that 12 VAC is

being supplied to the output board from the aux-

iliary transformer. It also shows that the 12 VAC

is being rectified to approximately 17 VDC. This

DC voltage is used to power the trigger circuit

and solenoid driver circuits incorporated on the

output board.

LED3: (Green) This light indicates that the air

solenoid driver circuit is functioning. When this

LED is lit, the air solenoid should be activated.

LED4: (Green) This light indicates that the trig-

ger circuit on the output board has been activat-

ed. This LED should be lit when the torch or

remote trigger is closed. This trigger circuit, on

the output board, then sends a signal to the

control board.

LED5: (Green) This light indicates that the elec-

trode solenoid driver circuit is functioning. When

this light is lit, the electrode solenoid should be

activated. The electrode solenoid should be

energized during gas (air) pre-flow time. During

pilot and cutting arc periods, the LED should be

off. When the arc goes out, the machine enters

the post-flow state. Two seconds after the start

of post-flow the electrode solenoid is activated a

few times. The LED should blink to indicate this

activity. The electrode solenoid will then be

energized for the duration of post-flow. (The LED

should be on.)