MACHINE INTERFACE

The PRO-CUT 80 comes standard with a machine

interface. Interface signals provided include: arc start,

arc initiated, and arc voltage. These signals are acces-

sible through the 14 pin MS connector on the case

front.

ARC START:

The Arc Start circuit allows for triggering of the power

source to commence cutting. This circuit can be

accessed through pins K and M of the 14 pin MS con-

nector. The circuit has a 17 VDC nominal open circuit

voltage and requires a dry contact closure to activate.

ARC INITIATED:

The Arc Initiated circuit provides information as to

when a cutting arc has transferred to the work piece.

This circuit can be accessed through pins I and J of the

14 pin MS connector. The circuit provides a dry contact

closure when the arc has transferred. Input to this cir-

cuit should be limited to 0.3 A for either 120VAC or

30VDC.

ARC VOLTAGE:

The Arc Voltage circuit can be used for activating a

torch height control. This circuit can be accessed

through pins D and G of the 14 pin MS connector. The

circuit provides full electrode to work arc voltage (no

voltage divider, 335VDC maximum).

Users wishing to utilize the Machine Interface can

order a K867 Universal Adapter (please adhere to the

pin locations stated above) or manufacture a 14 pin MS

connector cable assembly.

OPERATION

B-9

B-9

PRO-CUT 80

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

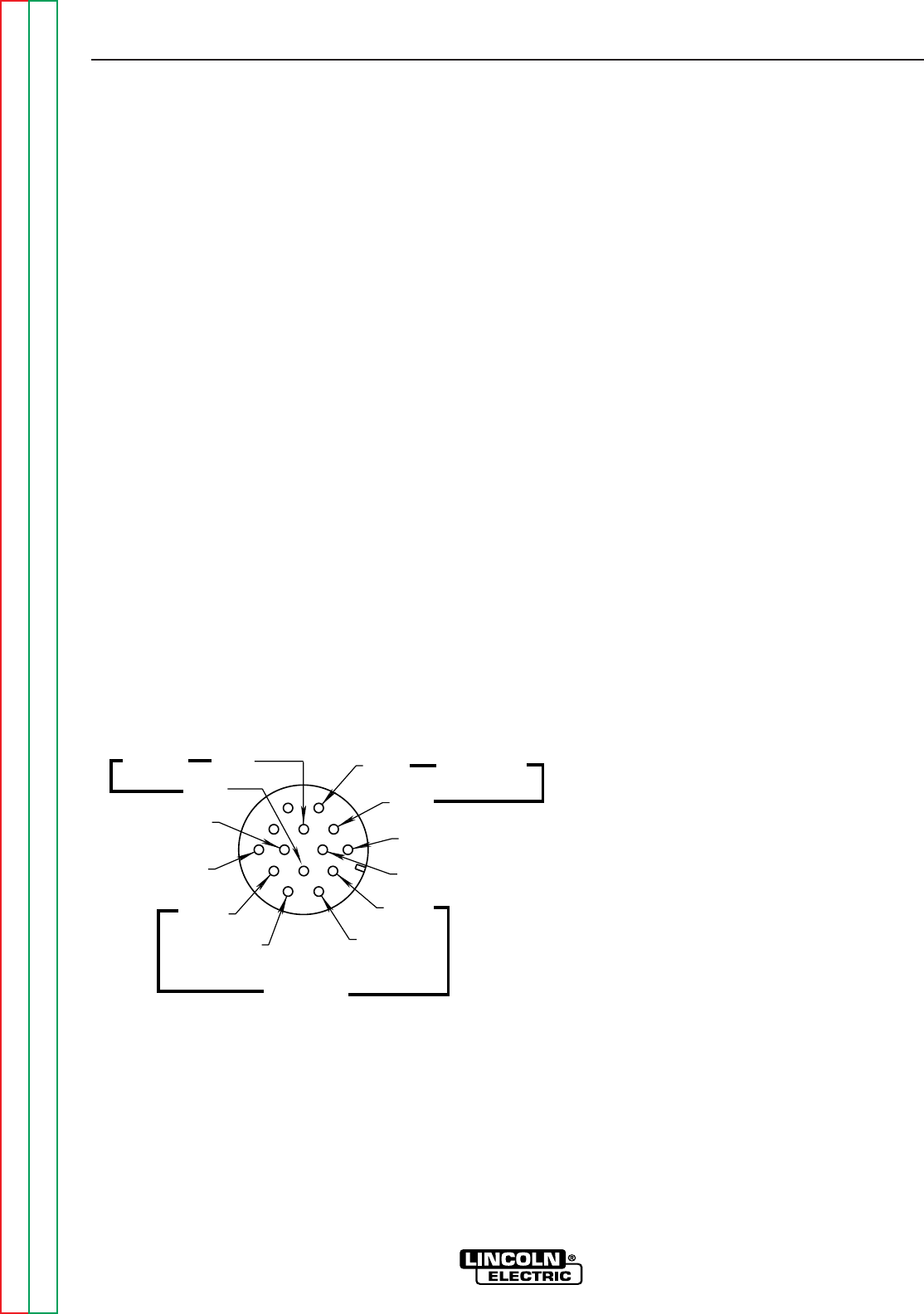

14-PIN BOX RECEPTACLE, FRONT VIEW

J=347

I=348

H

N

G=343

F

E

D=344

C

L

Arc Start

Arc Voltage

Arc Initiated

M=4A

K=2A