THEORY OF OPERATION

E-4 E-4

PRO-CUT 80

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

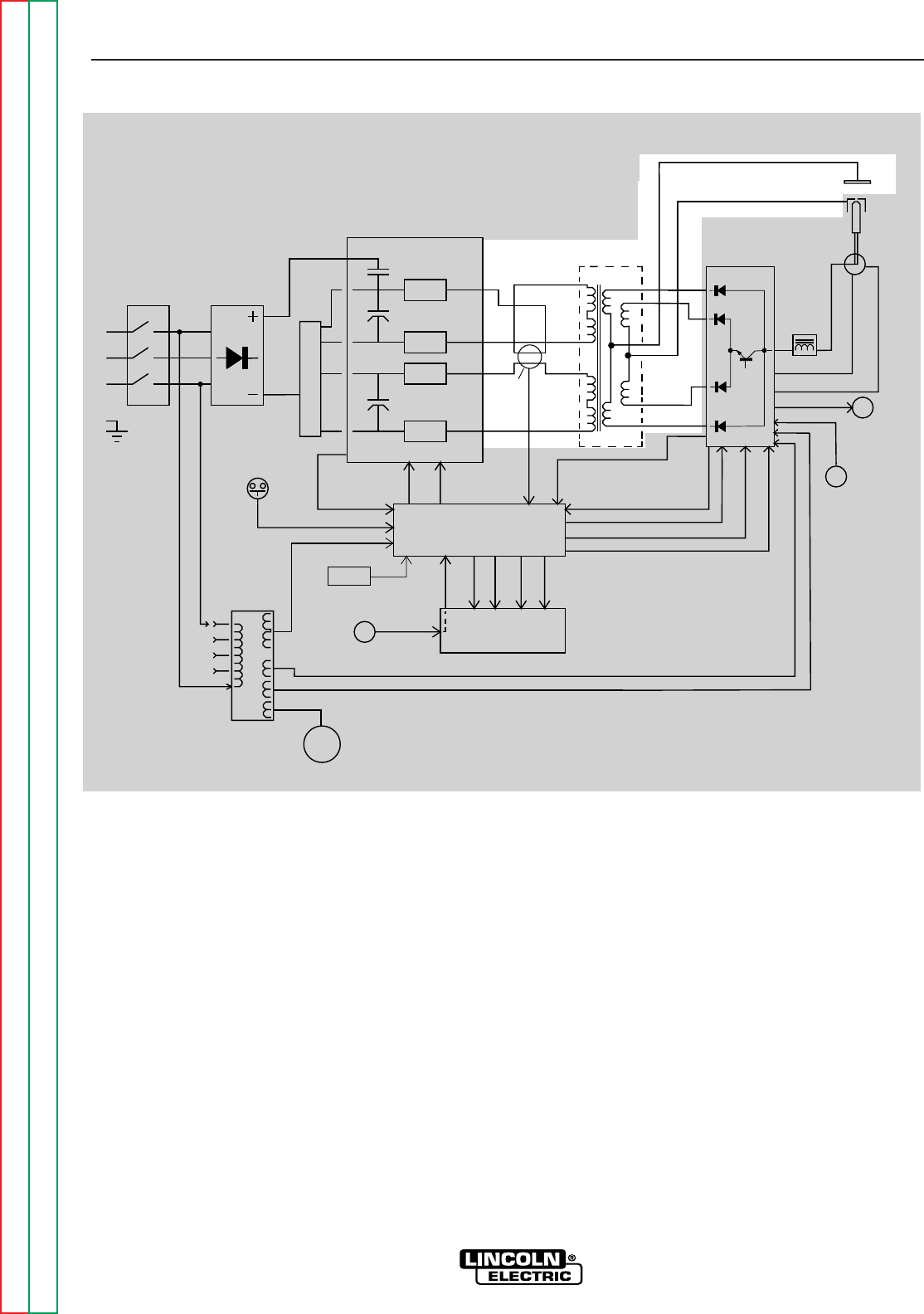

FIGURE E.4 – MAIN TRANSFORMER

INPUT

LINE

SWITCH

INPUT

RECTIFIER

FAN

MOTOR

"A"

L

E

A

D

AUXILIARY

TRANSFORMER

OUTPUT

CONTROL

AIR

PRESSURE

SWITCH

P

R

O

T

E

C

T

O

N

I

SIGNAL

CR 1

DRIVE

SIGNAL

RELAY

IGBT

GATE

SIGNALS

R

E

A

D

Y

A

I

R

L

O

W

T

H

E

R

M

A

L

S

A

F

E

Y

T

TRIGGER & SAFETY

ELECTRODE & TRANSFER

CURRENT FEEDBACK

PILOT ENABLE

ELECTRODE SOLENOID ENABLE

AIR SOLENOID ENABLE

AIR

SOLENOID

TRIGGER & SAFETY

E

L

E

C

T

R

O

D

E

S

O

L

E

N

O

I

D

TORCH

CONNECTOR

ELECTRODE

NOZZLE

WORK

R

E

C

O

N

N

E

C

T

S

W

T

C

H

I

POWER BOARD

CR 1

RELAY

IGBT

IGBT

IGBT

IGBT

CAPACITOR

CAPACITOR

CURRENT

TRANSFORMER

CONTROL BOARD

DISPLAY BOARD

18/36VAC

12VAC

24VAC

MAIN

TRANSFORMER

OUTPUT BOARD

CHOKE

PILOT

TRANSISTOR

THERMOSTATS

115VAC

REMOTE

INTERFACE

RECEPTACLE

&

2

& 2

MAIN TRANSFORMER

Each IGBT pair acts as a switch assembly. Each

assembly feeds a separate, oppositely wound primary

winding of the main transformer. The reverse direction

of current flow through the main transformer primaries

and the offset timing of the IGBT pairs induce an AC

square wave output signal at the secondary of the

main transformer.

The DC current flow through each primary winding is

redirected or "clamped" back to each respective filter

capacitor when the IGBTs are turned off. This is need-

ed due to the inductance of the transformer primary

winding.

The primary currents also pass through the current

transformer, which sends a signal to the control board.

If the primary currents are not equal, the control board

compensates by adjusting the IGBT gate signals.

The firing of both IGBT pairs occurs during halves of

the 50 microsecond intervals, creating a constant

20KHZ output.

The secondary portion of the main transformer is made

up of two separate windings. One secondary winding

supplies the electrode-to-work voltage. This is the

high current winding, which is capable of supplying

maximum output current during the cutting process.

The other secondary winding supplies the electrode-

to-nozzle voltage for the pilot arc current. The con-

ductor in this winding is smaller since the pilot current

is considerably less than the cutting current. While

one winding is conducting the other winding is at a lim-

ited voltage and aids in the arc transfer to and from the

workpiece.