Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-7 F-7

PRO-CUT 80

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed.

Call 1-800-833-9353.

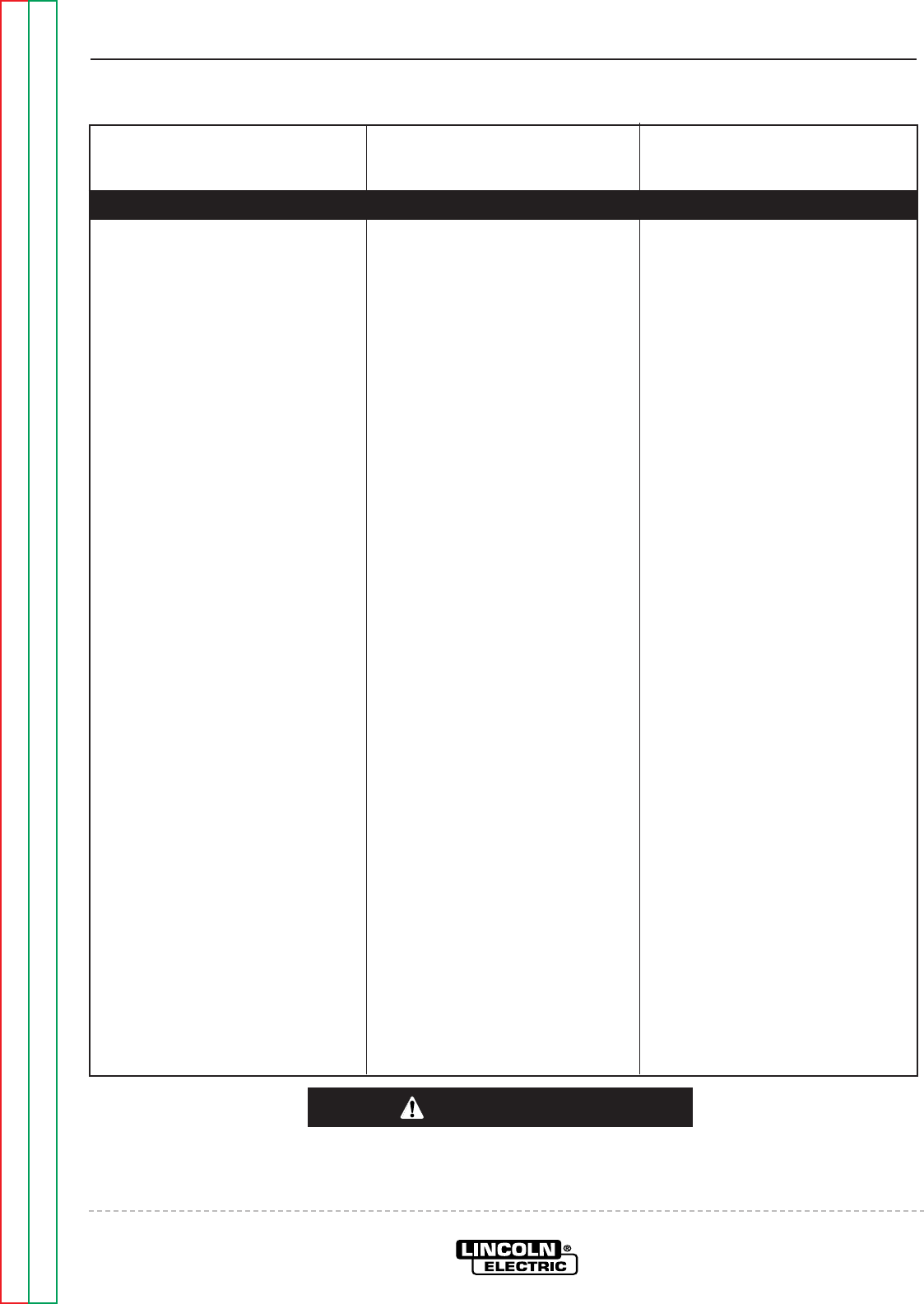

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

CUTTING PROBLEMS

The pilot arc is normal, but the arc

will not transfer to the workpiece.

1. Make sure the operating proce-

dure is correct for the process.

See the Operation section of

this manual.

2. Make sure the work clamp is

connected tightly to the work-

piece.

3. The workpiece must be electri-

cally conductive material.

1. Check the lead connections X2,

X4 and B21 at the output board.

2. Check the output control

potentiometer (R1). Normal

resistance is 10 ohms. Also

check the associated leads for

loose or faulty connections to

the display board. See the

Wiring Diagram.

3. Check leads #216, #218 and

#219 between the display

board and the control board.

Check for loose or faulty con-

nections. See the Wiring

Diagram.

4. The control board may be

faulty. Replace.

5. The output board may be faulty.

Perform the Output Board

Resistance Test.

6. The display board may be

faulty. Replace.