SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

Have qualified personnel do the maintenance work.

Always use the greatest care when working near mov-

ing parts.

If a problem cannot be corrected by following the

instructions, take the machine to the nearest Lincoln

Field Service Shop.

See additional warning information throughout this

manual.

MAINTENANCE

The only maintenance that may be required for the

Multi-Weld 350 is to clean out any accumulated dirt and

debris. Clogging could contaminate internal compo-

nents or obstruct proper cooling of the power compo-

nents, resulting in premature over-temperature shut-

down.

The recommended cleaning procedure is as follows:

1. Be sure to disconnect the Converter input cable to

remove its input power.

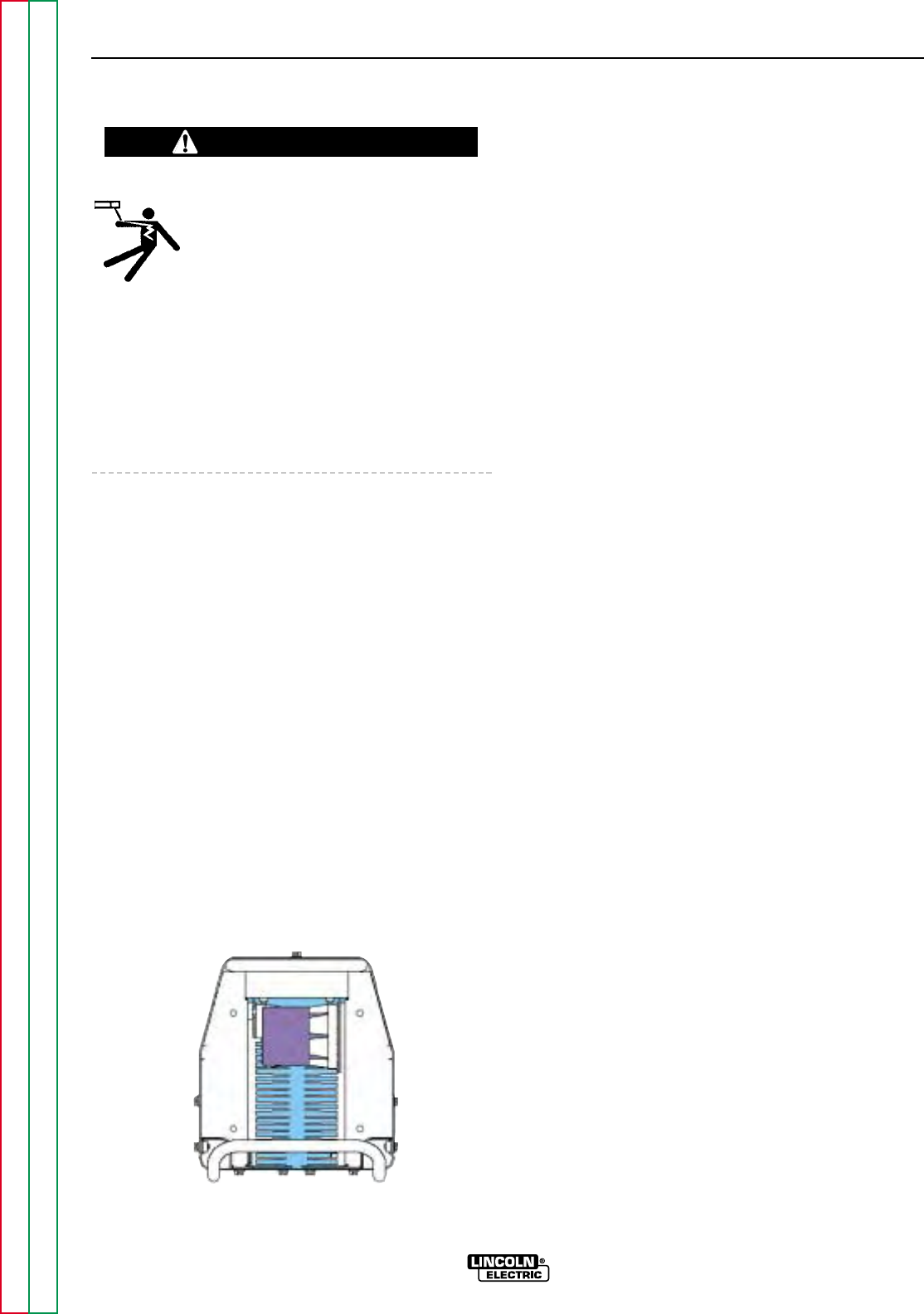

2. Remove the four screws securing the rear louver

panel and remove the panel to expose the cooling

tunnel heatsinks. (See Figure D.1 below.)

3. Holding the unit by the front handles, so the back is

facing down, shake the loose debris out of the unit.

Raking out the heatsink fins may be necessary for

jammed debris.

4. If necessary, remove the case wraparound cover.

Using the skid handles to hold the unit upside down,

carefully dump out any remaining loose debris or

carefully blow out using low pressure air.

5. Reassemble the cleaned out Converter by reversing

the above steps.

DIGITAL METER CALIBRATION

If calibration of either digital meter is ever necessary,

meter calibration adjustment trimmers are provided on

the Weld Control PC board inside the Control Module.

(See Figure D.2.) Calibration must be done with an

Output current load, so meters are displaying Actual

(not Preset) values. It is recommended that the cali-

bration levels be near the rating plate values, for best

accuracy, and compared to "master" meters with better

than 2% accuracy.

The accuracy of Actual AMPS meter should be within

3% of the welding amps monitored. The AMPS meter

trimmer (R561) is located near the center of the Weld

Control PC board just below the VOLTS meter trimmer

(R562). Clockwise rotation of the trimmer adjustment

screw will decrease the meter reading.

The accuracy of Actual VOLTS meter should be within

3% of the welding volts monitored. The VOLTS meter

trimmer (R562) is located near the center of the Weld

Control PC board just above the AMPS meter trimmer

(R561). Clockwise rotation of the trimmer adjustment

screw will decrease the meter reading. The “master”

voltmeter should be connected as close as possible to

the “ELECTRODE +” stud and “WORK -” lead bolt for

best accuracy.

D-2 D-2

MAINTENANCE

MULTI-WELD 350

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WARNING

FIGURE D.1 – TUNNEL HEATSINKS