Observe Safety Guidelines TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely,

contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-800-833-9353.

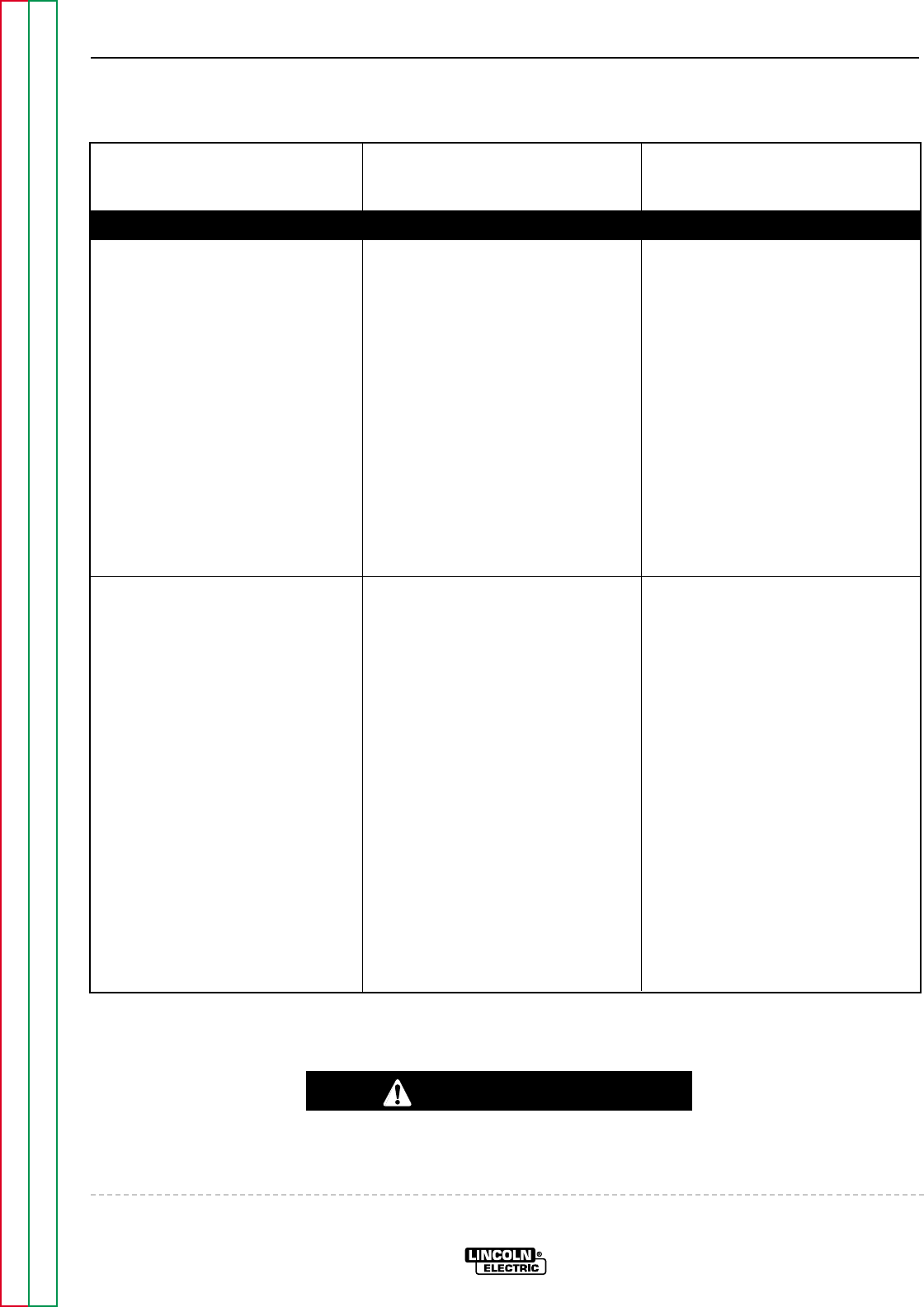

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

WELDING PROBLEMS

The welding output is high with no

control.

1. Check all input and output

cables for shorts. Check the

positive input and output cables

for “grounded” connections to

the machine’s case.

1. Check shunt feedback leads

R326, 327, R226, 227, plugs

P21 and P6, for loose or faulty

connections. See the Wiring

Diagram.

2. Check the continuity of leads

401, 301, 201, plugs P20, P22

and P31. See the Wiring

Diagram.

3. Check the Output Control R1

and the associated leads. See

the Wiring Diagram.

4. The Weld Control Board may be

Faulty.

No control of welding output. 1. The panel Output Control is dis-

abled when a remote control

device is plugged into the 6-pin

remote receptacle.

2. Check the welding cables for

loose or faulty connections.

1. Check the Output Control (R1)

and the associated leads for

loose or faulty connections.

2. Check all the plug connections

to the Weld Control Board for

loose or faulty connections.

See the Wiring Diagram.

3. The Weld Control Board may be

faulty. Replace.

F-10 F-10

TROUBLESHOOTING & REPAIR

MULTI-WELD 350

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC