TROUBLESHOOTING & REPAIR

F-59 F-59

MULTI-WELD 350

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

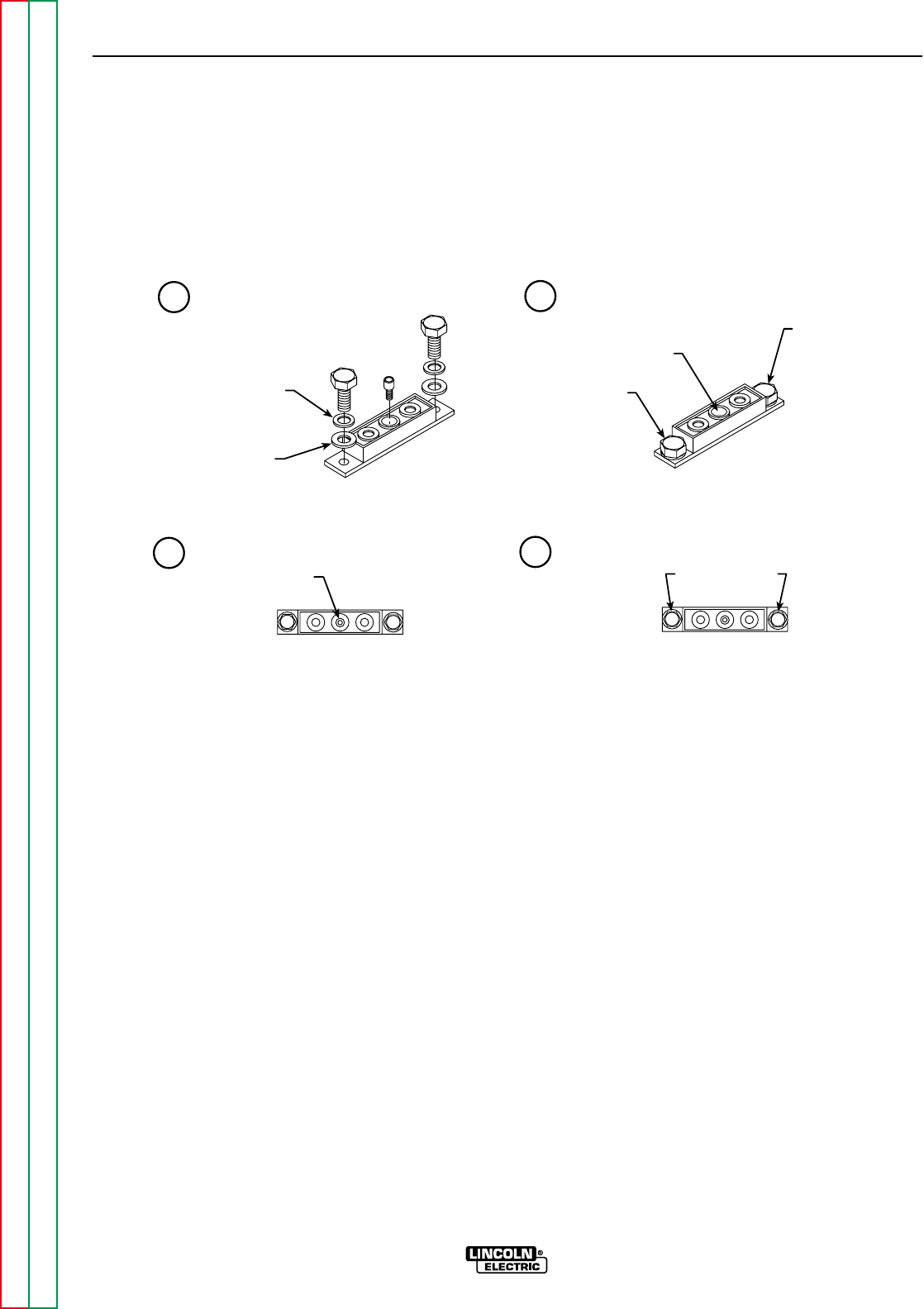

SPRING WASHER

PLAIN WASHER

2 TO 3

TURNS EACH

FINGER TIGHT

5.0-10 IN-LBS.

5.0-10 IN-LBS.

12-18 IN-LBS.

30-40 IN-LBS.

1

2

3

4

FIGURE F.16 – DIODE MODULE TIGHTENING SEQUENCE

DIODE MODULE REMOVAL AND REPLACEMENT(CONTINUED)

Refer to Figure F.16.

4. Place a spring washer then a flat washer

over each outer mounting screw and insert

them into the holes. Insert the allen head

screw into the center hole. Tighten all three

screws 2 – 3 turns each, finger-tight only.

(1)

5. Using the torque wrench and 7/16" socket,

tighten the outer screws to between 5.0 and

10 in-lbs. (2)

6. Using the torque wrench and 9/64" allen

head socket, tighten the center screw

between 12 and 18 in-lbs. (3)

7. Now tighten the two outer screws between

30 and 40 in-lbs. (4)

8. Place the negative capacitor strap over the

diode module and align the mounting holes.

Place a lock washer and two flat washers

over each 7/16" screw and insert them into

the holes. Using the torque wrench and

7/16" socket, tighten each screw between

30 and 40 in-lbs.

9. Install the 7/16" bolt, lock washer, flat

washer, heavy lead and negative strap to

the negative terminal on the capacitor.

Tighten the bolt to 50-60 in-lbs.

10. Remove the wooden blocking and careful-

ly lower the tunnel assembly onto the

machine base. Support the tunnel assem-

bly and turn the machine onto its side.

11. With the 3/8" wrench, install the four

screws that hold the tunnel assembly to the

machine base. Turn the machine back

upright.

12. Perform the Case Cover Assembly

Replacement procedure.