TROUBLESHOOTING & REPAIR

F-53 F-53

MULTI-WELD 350

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

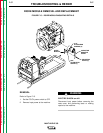

POWER CAPACITOR REMOVAL AND REPLACEMENT (CONTINUED)

7. Using the slot head screw driver, remove

the two screws and lock washers from the

tunnel assembly top cover. Then remove

the four screws, lock washers, and flat

washers that mount the Analog Control

Power Supply PC Board. This will allow

you to access the clamps that hold the

capacitors to their brackets in the heat

sinks.

8. Lift off the top cover of the tunnel assem-

bly. Peel away the adhesive-backed rub-

ber stripping (if present) as necessary.

Use care – the stripping may tear.

9. Using the slot head screw driver, loosen

the clamp from around the bracket of the

capacitor you want to remove.

10. Using the 7/16" wrench, remove heavy

leads #X1, #X4 and small leads #401 and

401A (left side) or #X1A and #X4A (right

side) of the capacitor terminals. Note the

fasteners for reassembly: bolt, lock wash-

er, and flat washer. See the Wiring

Diagram.

11. Using the 7/16" wrench, remove the two

bolts holding the negative strap to the

diode module. Note the fasteners for

reassembly: bolt, lock washer, two flat

washers.

12. Using the 7/16" wrench, remove the two

nuts holding the positive strap to the

Chopper PC board. Hold the bolt head

behind the board to remove each nut.

Note the fasteners for reassembly: flat

washer, lock washer, nut. Note the place-

ment of the reverse diode lead on the bot-

tom bolt.

13. Push the capacitor from the inside, out of

the heat sink. Note that the bracket stays

in the heat sink.

REASSEMBLY

1. Slide the capacitor into the heat sink.

Position the positive (+) terminal next to

the Chopper PC board.

2. Tighten the bracket clamp.

3. Replace the leads and straps as labeled

(Figure F.13) and tighten the fasteners.

Use the 7/16" socket and torque wrench to

tighten the capacitor terminal bolt to 50-60

in-lbs. Tighten the nuts holding the positive

strap to the Chopper PC board to 50-60 in-

lbs.

4. Tighten the two 7/16" screws that hold the

negative strap to the diode module to 30-40

in-lbs.

5. Replace any adhesive-backed rubber strip-

ping, if present, that was damaged during

disassembly.

6. Replace the Analog Control Power Supply

PC Board.

7. Replace the tunnel assembly top cover.

8. Connect the wire harness plug assemblies

above each Chopper PC Board and above

the tunnel assembly (four plugs total).

9. Perform the Case Cover Assembly

Replacement procedure.