NOTE: Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. Individual Printed Circuit Board Components are not available from Lincoln Electric. This information is pro-

vided for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the

machine.

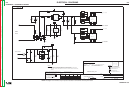

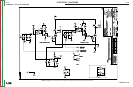

ELECTRICAL DIAGRAMS

G-7

COMMANDER 500

PC BOARD ASSEMBLY - CHOPPER PC BOARD

0

0

CAD

9-22-2000

MAP

FULL

2-10-98

t

UNLESS OTHERWISE SPECIFIED TOLERANCE

ON HOLE SIZES PER E2056

ON 2 PLACE DECIMALS IS .02

WITH PUBLISHED STANDARDS.

ON 3 PLACE DECIMALS IS .002

ON ALL ANGLES IS .5 OF A DEGREE

MATERIAL TOLERANCE (" ") TO AGREE

THE LINCOLN ELECTRIC CO.

CLEVELAND, OHIO U.S.A.

EQUIP.

TYPE

SCALE

SUBJECT

DR

DATE

CHK

REF.

SUP'S'D'G

SHT.

NO.

THE LINCOLN ELECTRIC CO.

THIS SHEET CONTAINS PROPRIETARY INFORMATION

OWNED BY

AND IS

NOT TO BE REPRODUCED, DISCLOSED OR USED

THE LINCOLN ELECTRIC CO.

L

L

WITHOUT THE EXPRESS PERMISSION OF

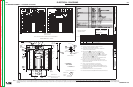

COMPONENT SIDE CIRCUITRY

OPPOSITE COMPONENT SIDE CIRCUITRY

ENGINE WELDERS

300 CHOPPER P.C. BOARD AS’BLY

L11068-1

5.75

0

NOTE: FOR BLANK SHEARING TOLERANCE SEE P.C. BOARD ASSEMBLY.

(MAKES 6 BOARDS)

BLANK PART NO. L11315-B

0

0

2

MAKE FROM S19399

11315-1

11315-1

L11315-1B0

MANUFACTURED AS:

IDENTIFICATION CODE

}

}

CAPACITORS = MFD/VOLTS

RESISTORS = OHMS

.490~.005

MAX.

R .045

EYELET DETAIL

.275

.285

4

3

N.E., N.F.

SIDE

OPPOSITE

.105

N.A. CAUTION: THIS DEVICE IS SUBJECT TO DAMAGE BY STATIC

ELECTRICITY. SEE E2454 BEFORE HANDLING.

NOTES :

SEALANT PRIOR TO ENCAPSULATION.

SOLDER BLOBS PERMITTED.

N.F. SOLDER EYELET SO THAT SOLDER COVERS ENTIRE EYELET AND ALL

AROUND EYELET ON OPPOSITE COMPONENT SIDE ONLY. NO ICICLES OR

SHOWN. EYELET MUST NOT SPIN AFTER CLINCHING.

N.E. FEMALE EYELET TO BE AGAINST THE OPPOSITE COMPONENT SIDE AS

PLACE SEALANT ALONG SIDE AND UNDER COMPONENTS.

N.C. THESE AREAS TO BE COVERED ON BOTH SIDES OF BOARD WITH

N.G. DO NOT COVER OVER COMPONENT C5 WITH SEALANT.

e.g. M16100-39 X XX XX ........

VENDOR CODE

VCE(SAT)

VGE(TH)

MAKE PER E1911

TEST PER E3846-CH

2

1

4

ITEM

REQ’D

PART NO.

IDENTIFICATION

2

3

4

5

T9147-11

1

1

P. C. BOARD BLANK

EYELETS (MALE)

EYELETS (FEMALE)

4

2.0 OZ.

E2861

SEALANT

T9147-15

M16100-39

ELECTRONIC MODULE

6

S20590-1

HEAT SINK

2

L11315-B

Ch’ge. Sht. No.

0

~.04

6.00

~.04

1

6

2.21

3.78

.475

2.80

4.55

~.02

N.C.

N.D.

N.C.

N.C.

OPPOSITE COMPONENT SIDE CIRCUITRYOPPOSITE COMPONENT SIDE CIRCUITRY

CRIMP HEIGHT

N.G.

1.75

1.012

3.60

VGE(TH) WITHIN 5 SORT CODES (0.5VSPAN) FOR THE SAME VCE(SAT) CODE

AND MANUFACTURING CODE.

N.H. ELECTRONIC MODULES ON A COMMON P.C. BOARD ASSEMBLY TO HAVE

N.A., N.H.

7

1

S18250-542

PLUG & LEAD ASSEMBLY

300

300

7

ITEM REQ’D PART NO. IDENTIFICATION

N.A.

XG-UF

CHOPPER300

C6 ˇ

L11315-1

1.575

1.425

.075

C2

Q1

CHOPPER

C5

R1

X1

300

C

L11315-1

RA

B1

B3

B2

B

B7

A2

A1

RA

B

N.J. THIS DIMENSION APPLIES TO TWO OF THE FOUR EYELETS

N.J.

(RESTRAINED)

N.J.

FOR PARTS ORDERS:

INCLUDE (1) L11167 PRINT

AND (1) T12837-1

XG-UF

4-14-2000

N.K.

ENCAPSULATE WITH E1844 (1 COAT)

N.D. INJECT SEALANT ITEM 5 THROUGH THE PC BOARD HOLES

MATERIAL AS PER APPROPRIATE MANUFACTURING WORK INSTRUCTIONS.

COVER ALL MODULE LEADS THAT PROTRUDE FROM THE NON-MODULE

SIDE OF THE BOARD WITH ITEM 5 SEALANT.

(10 HOLES) TO SEAL MODULE LEADS. CAVITY BETWEEN BOARD

AND MODULE TO BE COMPLETELY FILLED WITH ITEM 5 SEALANT

N.K. ELECTRONIC MODULES TO BE ASSEMBLED AND ENCAPSULATD PER E3875.

G-7

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC