COOLING SYSTEM: The cooling system of the Deutz

engine needs to be checked and cleaned periodically.

Consult the engine Operation Manual for the proper

frequency and procedure.

COOLING BLOWER BELT: The following procedure

should be followed to replace the cooling blower belt:

1. Allow the machine to cool.

2. Unfasten and slide the battery holder out from the

welder.

3. Disconnect the negative battery cable.

4. Remove the engine case side.

5. Loosen the air cleaner hose clamp and detach the

hose.

6. Remove the engine end panel with air box and air

cleaner attached for access to the engine.

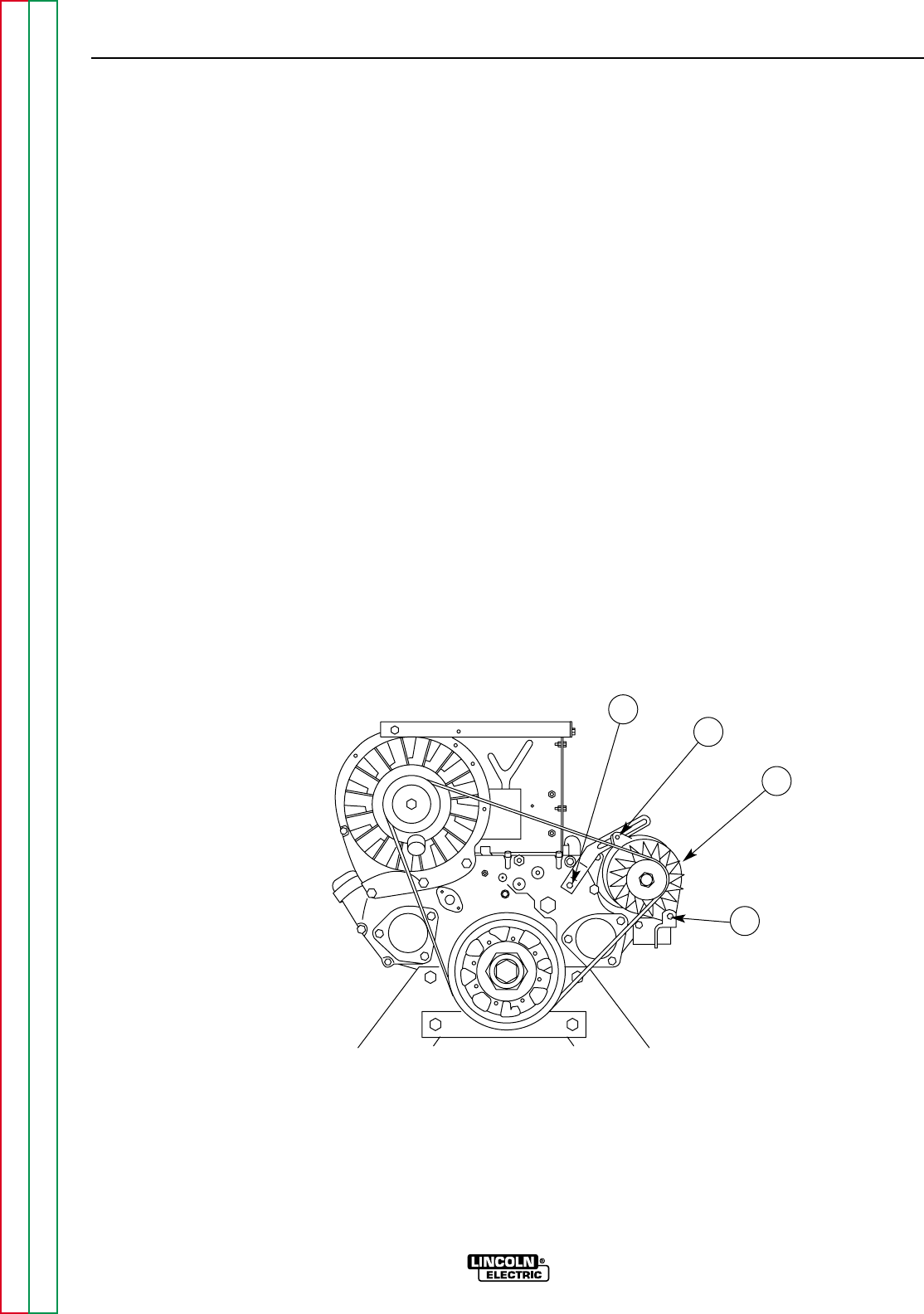

7. See Figure D.4. Loosen the alternator mounting

bolts (1, 2, 3) and rotate the alternator toward the

engine.

8. Remove the old cooling blower belt and install a

new one.

9. Push outward on the alternator (4) and adjust the

cold belt tension to 63-73 lbs. (10-15 mm maxi-

mum deflection) midway between any two pulleys.

Tighten bolts (1), (2), (3).

10. Reinstall the air cleaner hose, engine case side,

and engine end panel. Reattach the negative bat-

tery cable. Slide in and refasten the battery holder.

11. Check the cooling blower belt tension after 100

hours of operation. (Follow seps 1-6; 9 and 10.)

D-7 D-7

MAINTENANCE

COMMANDER 500

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE D.4 – COOLING BLOWER BELT REPLACEMENT AND ADJUSTING

1

2

4

3